Ultrasonic cleaning circulating water tank for liquid crystal screen cleaning machine

A technology for circulating water tanks and liquid crystal screens, applied in cleaning methods and appliances, cleaning methods using liquids, optics, etc., can solve the problems of inconvenient cleaning and maintenance of circulating water tanks, inconvenient disassembly and assembly of circulating water tanks, etc., to improve the convenience of maintenance, Easy to assemble and improve installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

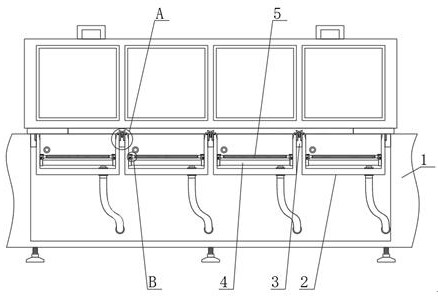

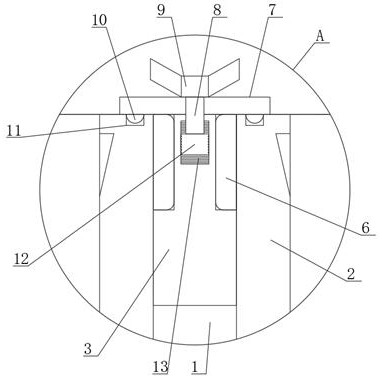

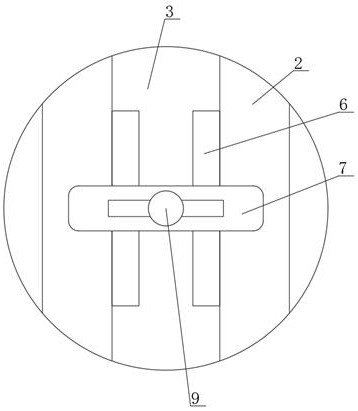

[0024] see Figure 1 to Figure 4 , the present invention provides a technical solution: a liquid crystal screen cleaning machine uses ultrasonic waves to clean the circulating water tank, including a liquid crystal screen cleaning machine body 1 and a plurality of circulating water tanks 2 arranged inside the liquid crystal screen cleaning machine body 1, and the inside of each circulating water tank 2 Ultrasonic generating devices 4 are installed at the bottom, the inner wall of the liquid crystal screen cleaning body 1 is welded and fixed with supporting beams 3 relative to both sides of each circulating water tank 2, and hanging blocks 6 are welded and fixed on both sides of each circulating water tank 2 , both sides of the support beam 3 are provided with hanging grooves corresponding to the hanging block 6, the hanging block 6 is hung in the hanging groove, and the top of the supporting beam 3 is provided with a fixing mechanism corresponding to the hanging block 6, and th...

Embodiment 2

[0032] see figure 1 , figure 2 , image 3 and Figure 5 , the present invention provides a technical solution: a liquid crystal screen cleaning machine uses ultrasonic waves to clean the circulating water tank, including a liquid crystal screen cleaning machine body 1 and a plurality of circulating water tanks 2 arranged inside the liquid crystal screen cleaning machine body 1, and the inside of each circulating water tank 2 Ultrasonic generating devices 4 are installed at the bottom, the inner wall of the liquid crystal screen cleaning body 1 is welded and fixed with supporting beams 3 relative to both sides of each circulating water tank 2, and hanging blocks 6 are welded and fixed on both sides of each circulating water tank 2 , both sides of the support beam 3 are provided with hanging grooves corresponding to the hanging block 6, the hanging block 6 is hung in the hanging groove, and the top of the supporting beam 3 is provided with a fixing mechanism corresponding to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com