Preparing method and using method of aluminum electrolytic anode covering device

A technology of aluminum electrolysis anode and covering device, which is applied in the field of aluminum electrolysis anode coverage and aluminum electrolysis waste recycling, which can solve the problems of complex operation of aluminum electrolysis anode coverage and high labor intensity of workers, so as to improve the quality of molten aluminum and realize mechanized operation , Change the effect of adding method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below by embodiment the present invention will be further described.

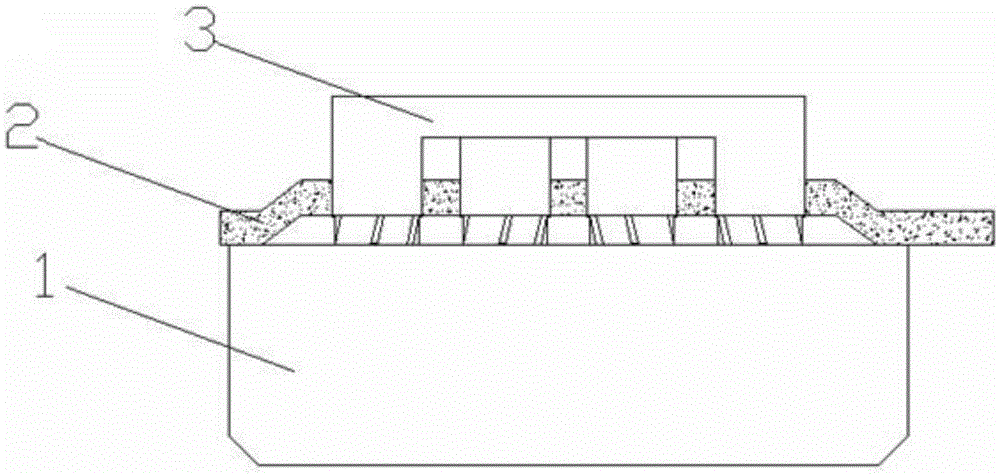

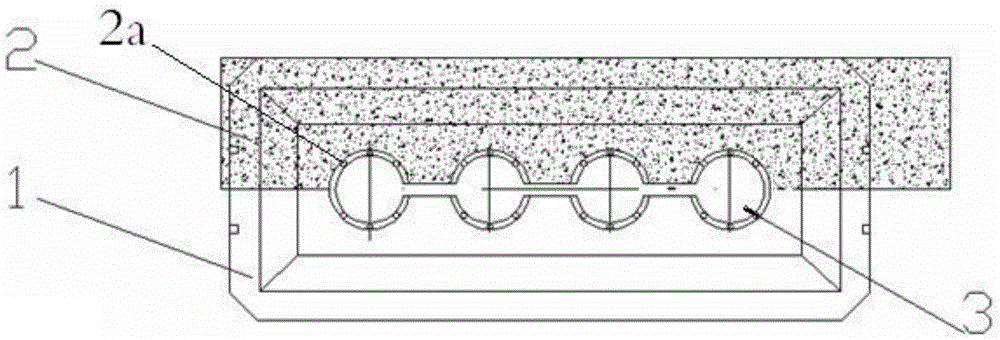

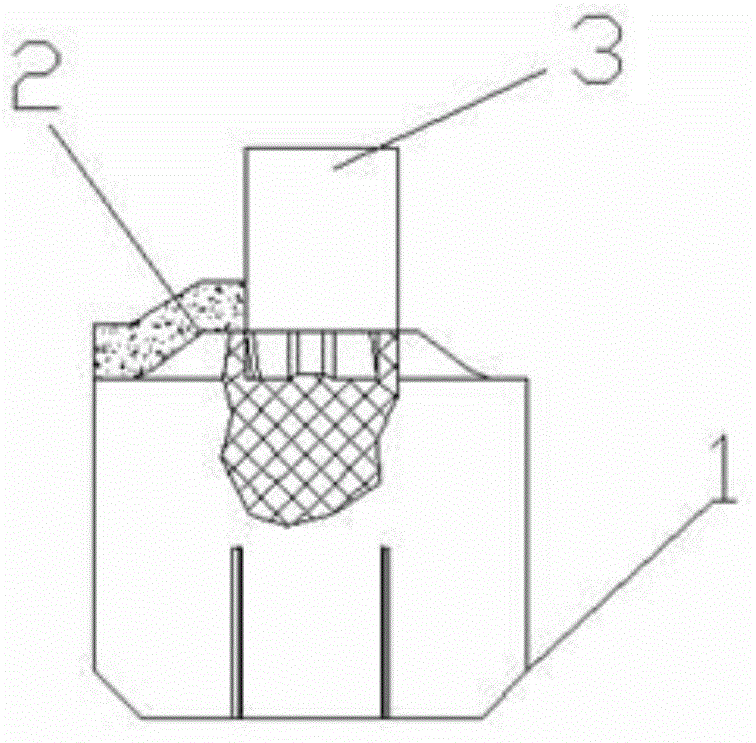

[0025] A method for preparing an anode covering device for aluminum electrolysis, the method is that the slurry formed by stirring and leaching aluminum ash with water is subjected to pressurized water immersion and three-stage countercurrent washing processes, and contains 5-50% Al(OH) 3 (mass ratio) aluminum ash cleaning slag is put into the mold, pressed with a pressure molding machine, and the Al(OH) contained in the aluminum ash cleaning slag is used 3 directly as a self-adhesive. Such as Figure 4 As shown, the specific steps are as follows:

[0026] a. The scum produced during the production of aluminum electrolytic remelting aluminum ingots or aluminum alloy smelting process, that is, aluminum ash, is stirred and leached with water to form flue gas (ammonia gas) and slurry. The ammonia gas is absorbed by water to prepare ammonia water, and the slurry is sent to pressurization Leaching, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com