A kind of high-purity propane production method for environmentally friendly refrigerant r290

A production method and high-purity technology, applied in chemical instruments and methods, purification/separation of hydrocarbons, hydrocarbons, etc., can solve the problems of low purity of propane, inability to use it as a refrigerant, and production costs, and achieve low reaction temperature , low production cost, low device investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Feedstock 1 contained 86% by weight of propane, 1.0% by weight of ethane, 1.5% by weight of propylene, 5.5% by weight of butane and 5.0% by weight of butene , The pentane content is 1.0%. In addition, the water content in the raw material 1 was 150 ppm (weight) and the sulfur content was 36 ppm (weight).

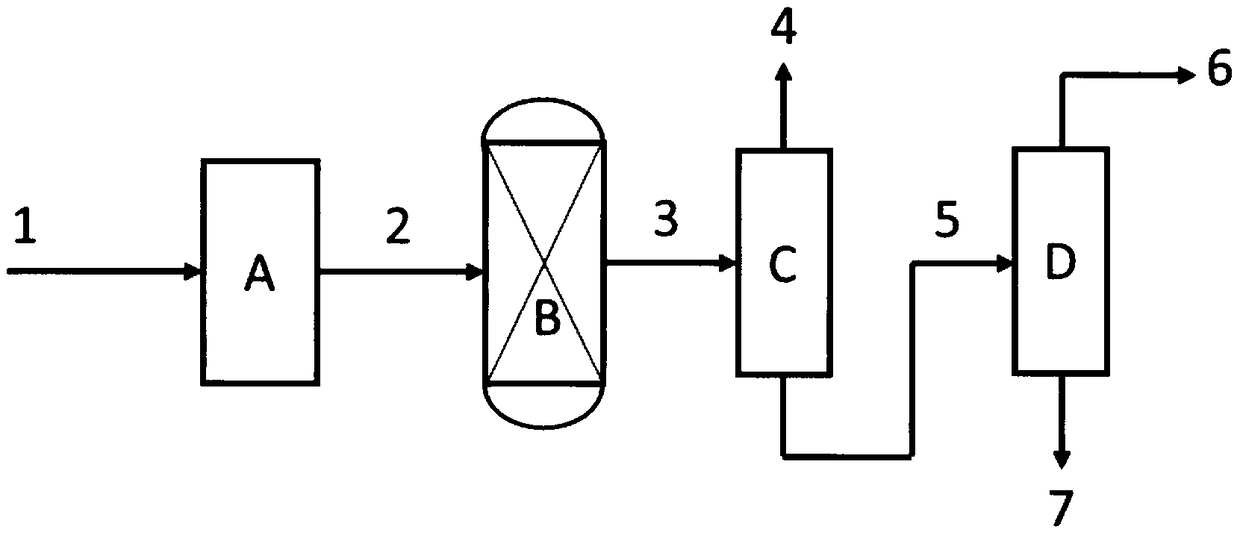

[0028] according to figure 1 The raw material 1 of the process shown enters the raw material pretreatment unit. The raw material pretreatment unit includes a desulfurization reactor and a dryer for desulfurization and dehydration. After treatment, the water content is less than 5ppm (weight) and the sulfur content is less than 1ppm (weight).

[0029] The hydrogenation reactor is a fixed bed reactor, the hydrogenation catalyst carrier of packing is alumina, the active component of the catalyst is palladium, and the auxiliary agent is cobalt, and the specific composition (weight) is 2.5% of palladium, 0.5% of cobalt, and 97% of alumina . The protective agent in the h...

Embodiment 2

[0034] Feedstock 1 contained 93% by weight of propane, 0.5% by weight of ethane, 2.5% by weight of butane, 3.0% by weight of butene and 1.0% by weight of pentane. In addition, the water content in the raw material 1 was 500 ppm (weight) and the sulfur content was 60 ppm (weight).

[0035] according to figure 1 The raw material 1 of the process shown enters the raw material pretreatment unit. The raw material pretreatment unit includes two desulfurization reactors and two dryers for desulfurization and dehydration. After treatment, the water content is less than 10ppm (weight) and the sulfur content is less than 1ppm (weight).

[0036] The hydrogenation reactor is a fixed-bed reactor, the hydrogenation catalyst carrier is alumina, the catalyst active component is nickel, and the auxiliary agent is molybdenum. The specific composition (weight) is 3.5% nickel, 0.1% molybdenum, and 96.4% alumina . The protective agent in the hydrogenation reactor is a mixture of silicon oxide an...

Embodiment 3

[0041]Feedstock 1 contained 96% by weight of propane, 0.1% by weight of ethane, 0.9% by weight of propylene, 1.5% by weight of butane and 1.0% by weight of butene , The pentane content is 0.5%. In addition, the water content in the raw material 1 was 100 ppm (weight) and the sulfur content was 10 ppm (weight).

[0042] according to figure 1 The raw material 1 of the process shown enters the raw material pretreatment unit. The raw material pretreatment unit includes a desulfurization reactor and two dryers for desulfurization and dehydration. After treatment, the water content is less than 5ppm (weight) and the sulfur content is less than 1ppm (weight).

[0043] The hydrogenation reactor is a trickle bed reactor, the loaded hydrogenation catalyst carrier is activated carbon, the active component of the catalyst is platinum, the auxiliary agent is cobalt, and the specific composition (weight) is 0.5% platinum, 0.05% cobalt, and the rest is active carbon. The protective agent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com