Single crystal gold nanosphere and preparation method thereof

A technology of gold nanospheres and spheres, which is applied in the field of monodisperse single crystal gold nanospheres and its preparation, can solve the problem of inability to synthesize single crystal gold nanospheres with uniform size, irregular shape of spherical gold nanoparticles, particle surface Unsmooth and other problems, to achieve the effect of abundant raw materials, high yield and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

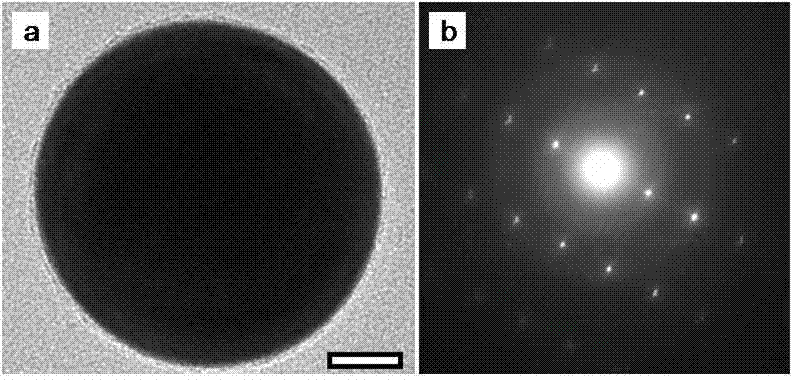

[0028] Preparation of 50 nm single crystal gold nanospheres

[0029] First, add diethylene glycol diacrylate phthalate (PDDA, Mw=100000-200000, 20 wt%) aqueous solution to the ethylene glycol solution, stir well to obtain a mixed solution; then add Chlorauric acid (HAuCl 4 ), and a small amount of silver nitrate (AgNO 3 ) and ferric chloride (FeCl 3) aqueous solution to obtain a reaction precursor solution, in which, diethylene glycol diacrylate (PDDA), chloroauric acid (HAuCl 4 ), silver nitrate (AgNO 3 ), ferric chloride (FeCl 3 ) in the precursor are 0.025 mol / L, 0.0005 mol / L, 0.00002 mol / L, 0.000000125 mol / L; subsequently, the reaction precursor solution is placed at 220 ℃ for 0.5 hours to obtain a red colloidal solution , after naturally cooling to room temperature, use a high-speed centrifuge to centrifuge at a speed of 14,500 rpm for 30 minutes, remove the colorless solution in the centrifuge tube, and obtain the precipitated product; then use deionized water to ul...

Embodiment 2

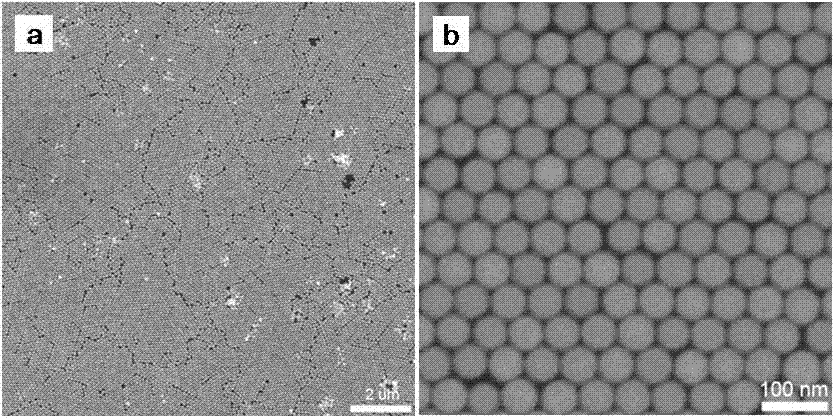

[0031] Preparation of 100 nm Single Crystal Gold Nanospheres

[0032] First, add diethylene glycol diacrylate phthalate (PDDA, Mw=100000-200000, 20 wt%) aqueous solution to the ethylene glycol solution, stir well to obtain a mixed solution; then add Chlorauric acid (HAuCl 4 ) and a small amount of silver nitrate (AgNO 3 ) and ferric chloride (FeCl 3 ) aqueous solution to obtain a reaction precursor solution, in which, diethylene glycol diacrylate (PDDA), chloroauric acid (HAuCl 4 ), silver nitrate (AgNO 3 ), ferric chloride (FeCl 3 ) concentrations in the precursor are 0.025 mol / L, 0.0005 mol / L, 0.00002 mol / L, 0.000001 mol / L; subsequently, react the precursor solution at 220 ℃ for 1 hour to obtain a red colloidal solution , after naturally cooling to room temperature, use a high-speed centrifuge to centrifuge at a speed of 12,000 rpm for 20 minutes, remove the colorless solution in the centrifuge tube, and obtain a red precipitate product; then use deionized water to ultr...

Embodiment 3

[0034] Preparation of 150 nm Single Crystal Gold Nanospheres

[0035] First, add diethylene glycol diacrylate phthalate (PDDA, Mw=100000-200000, 20 wt%) aqueous solution to the ethylene glycol solution, stir well to obtain a mixed solution; then add Chlorauric acid (HAuCl 4 ), and a small amount of silver nitrate (AgNO 3 ) and ferric chloride (FeCl 3 ) aqueous solution to obtain a reaction precursor solution, in which, diethylene glycol diacrylate (PDDA), chloroauric acid (HAuCl 4 ), silver nitrate (AgNO 3 ), ferric chloride (FeCl 3 ) in the precursor are 0.025 mol / L, 0.0005 mol / L, 0.00002 mol / L, 0.0000015 mol / L; subsequently, react the precursor solution at 220 ℃ for 1.5 hours to obtain a red colloidal solution , after naturally cooling to room temperature, use a high-speed centrifuge to centrifuge at a speed of 10,000 rpm for 10 minutes, remove the colorless solution in the centrifuge tube, and obtain a red precipitate product; then use deionized water to ultrasonically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com