Manufacturing method of training clothes using ems

A clothing manufacturing and clothing technology, applied in the field of training clothing manufacturing using EMS, can solve problems such as lack of fixation stability, automatic stitching completion, and comfort effects, etc., to achieve good electrical conductivity, low silver loss rate, and comfortable fit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0042] A method for manufacturing training garments using EMS, comprising the steps of:

[0043] 1) Preparation of close-fitting electrode 1:

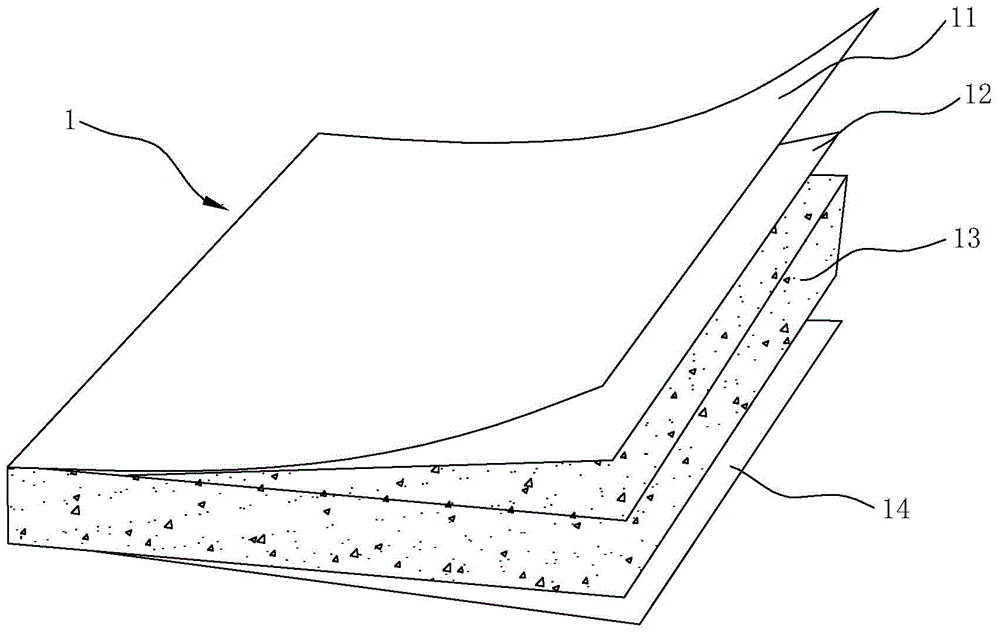

[0044] seefigure 1 , the electrodes include silver-plated cloth 11, film 12, elastic layer 13 and base cloth 14 arranged in sequence, and are composited to form electrodes. Combined muscle, its making comprises the following steps:

[0045] (1) Make silver-plated cloth 11: in the present invention, select nylon fiber to add spandex to weave elastic fabric (warp knitting, weft knitting or woven fabric) for use, nylon fiber is preferred, is thinner fiber, the basis of elastic fabric The silver-plated cloth 11 is obtained by doing chemical silver plating (coating silver glue) on the surface. The surface chemical silver plating technology on the nylon fiber is relatively mature, which can ensure that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com