Low-temperature plasma generator with hexagon pipe-type structure

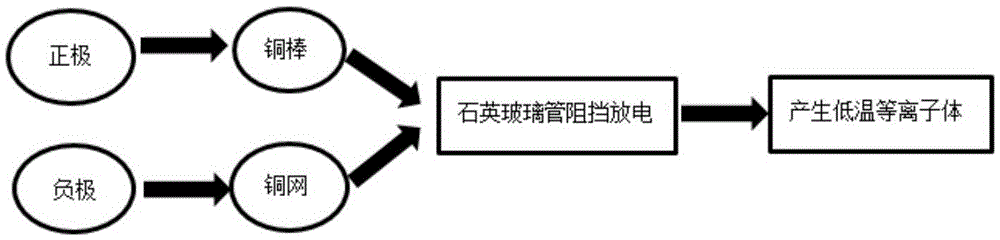

A low-temperature plasma and generator technology, applied in the direction of plasma, electrical components, etc., can solve the problems of increasing the use of dielectric layer materials, large demand for plate raw materials, and the space utilization rate has not reached the highest level, so as to improve the space utilization rate. , the effect of saving usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

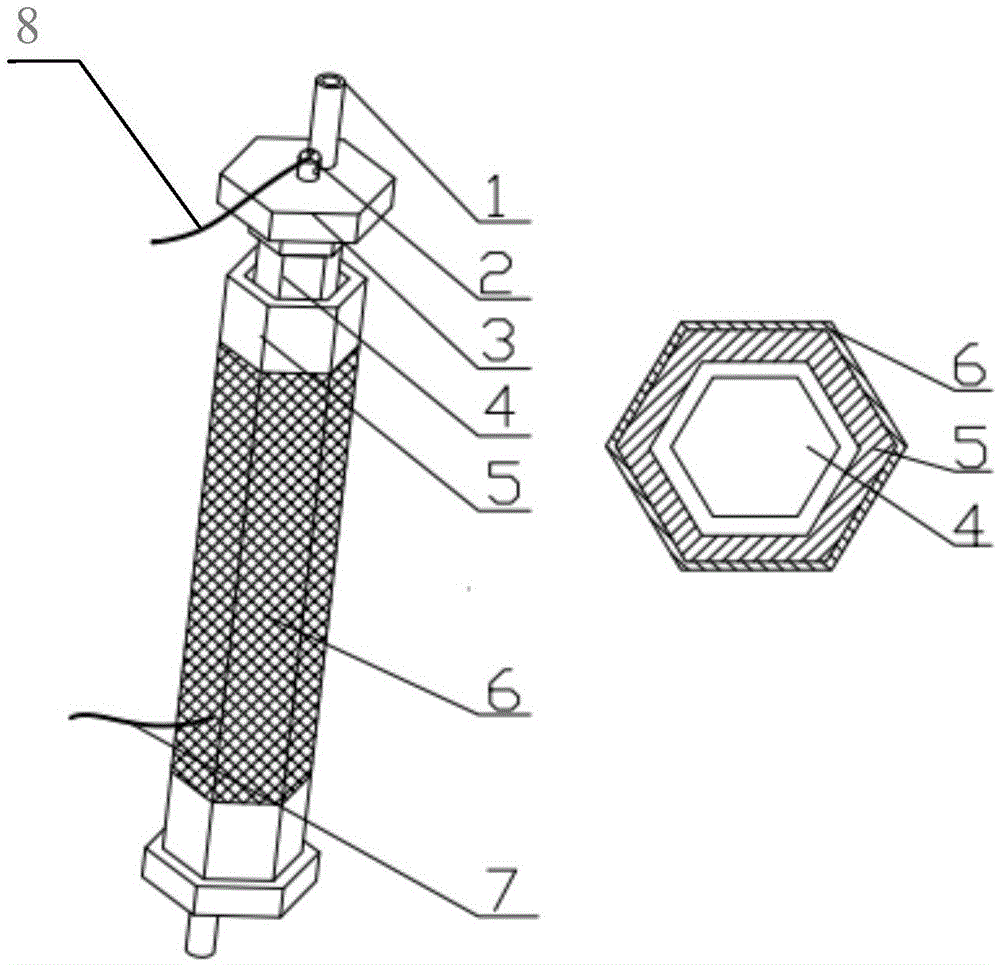

[0010] The present invention can be used to remove harmful inorganic (NO x , SO x ) and organic gases (VOCs). The invention proves through experiments that the single low-temperature plasma generator with hexagonal tubular structure can achieve above 99% removal rate of the above gases.

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. Advantageous features of the present invention will be apparent from the following description and claims. It should be noted that the drawings are all in a very simplified form and use very precise ratios, and are only used for the purpose of clearly and conveniently assisting in describing the embodiments of the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not constitute a conflict with each other.

[0012] Such as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com