Method for constructing large-area, flexible, wearable organic nano-wire field-effect transistor array by using adhesive tape as substrate

A technology of field-effect transistors and nanowire arrays, applied in the field of organic nanowire field-effect transistor arrays, can solve problems such as limitations, less research, and difficult transfer processes, and achieve the effects of maintaining proper performance, low cost, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] 4) Preparation of the insulating layer: use the magnetron sputtering method to coat a layer of Si3N4 on the plated gate substrate as the insulating layer;

[0037] 5) Preparation of source and drain electrodes: on the substrate coated with an insulating layer, metal material gold is deposited as source and drain electrodes by photolithography, development, and evaporation;

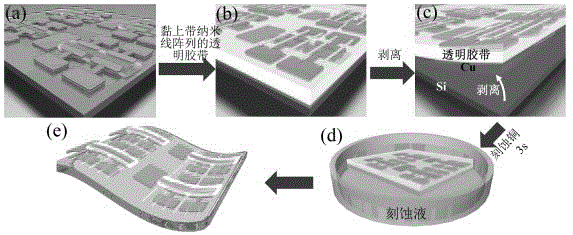

[0038] 6) Growth and transfer of nanowire arrays: With the assistance of gratings, PDMS templates are prepared, nanowire arrays are grown by physical vapor deposition (PVD), and nanowire arrays are transferred to the tape using tape, and then transferred to the plated electrodes on Cu / Si substrates.

[0039] 7) Device construction: Since the adhesive force between the adhesive tape and copper is stronger than that between silicon and copper, the adhesive force of the adhesive tape can be used to directly separate the copper from the silicon substrate, and further separate the electrodes and nanowire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com