Plasma vacuum pump

A vacuum pump and plasma technology, applied in ion diffusion discharge tubes, particle separation tubes, etc., can solve problems such as very high initial pressure requirements, resistance to atmospheric shock, damage to molecular pumps, etc., and achieve simple structure, low cost, and no vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

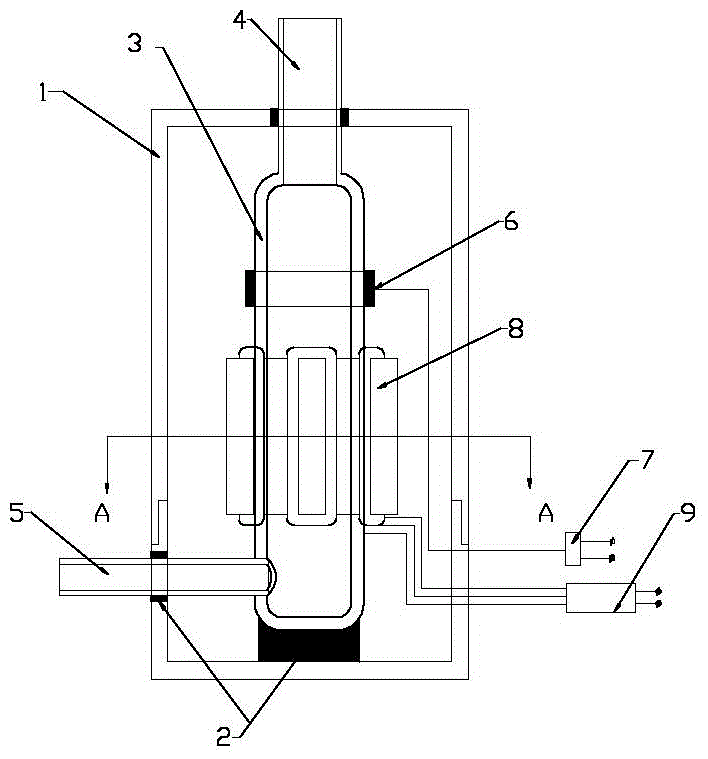

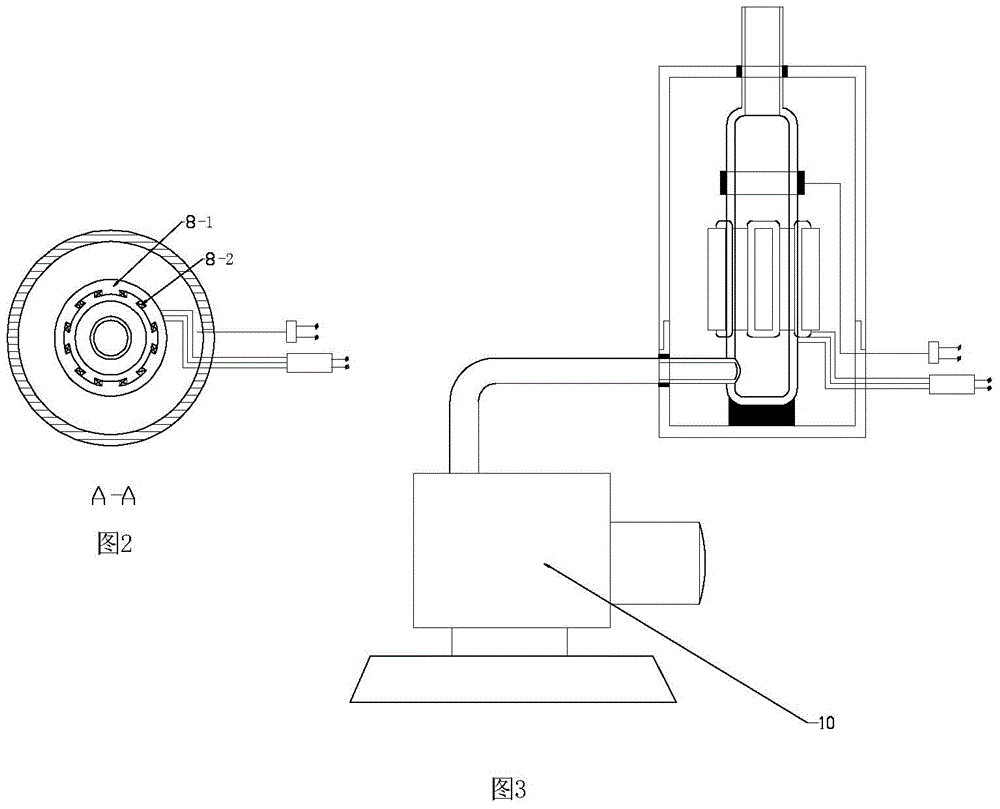

[0018] Such as figure 1 , 2 Shown: a plasma vacuum pump, including a casing 1, a glass pump body 3 set in the casing, an air intake pipe 4 and an exhaust pipe 5 connected to the glass pump body 3, and an electron emission ring 6 set on the glass pump body 3 And the rotating coil 8, the high-frequency generator 7 for the electron emission ring 6 power supply, the frequency converter 9 for the rotating coil 8 power supply; it is characterized in that: the described glass pump body 3 is that the quartz glass tube is made into a bottle shape, and the glass Both ends of the pump body 3 are welded with an intake pipe 4 and an exhaust pipe 5; the exhaust pipe 5 is welded in the radial direction of the glass pump body 3; the electron emission ring 6 is set on the front of the glass pump body 3; The rotating coil 8 is set in the middle and rear part of the glass pump body 3; the glass pump body 3 with the electron emission ring 6 and the rotating coil 8 is inserted into the shell 1; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com