Drill bit water combined integrate inserts

A combined drill technology, which is applied in drilling tool accessories, drill repairing, manufacturing tools, etc., can solve the problem of insufficient hole precision after machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

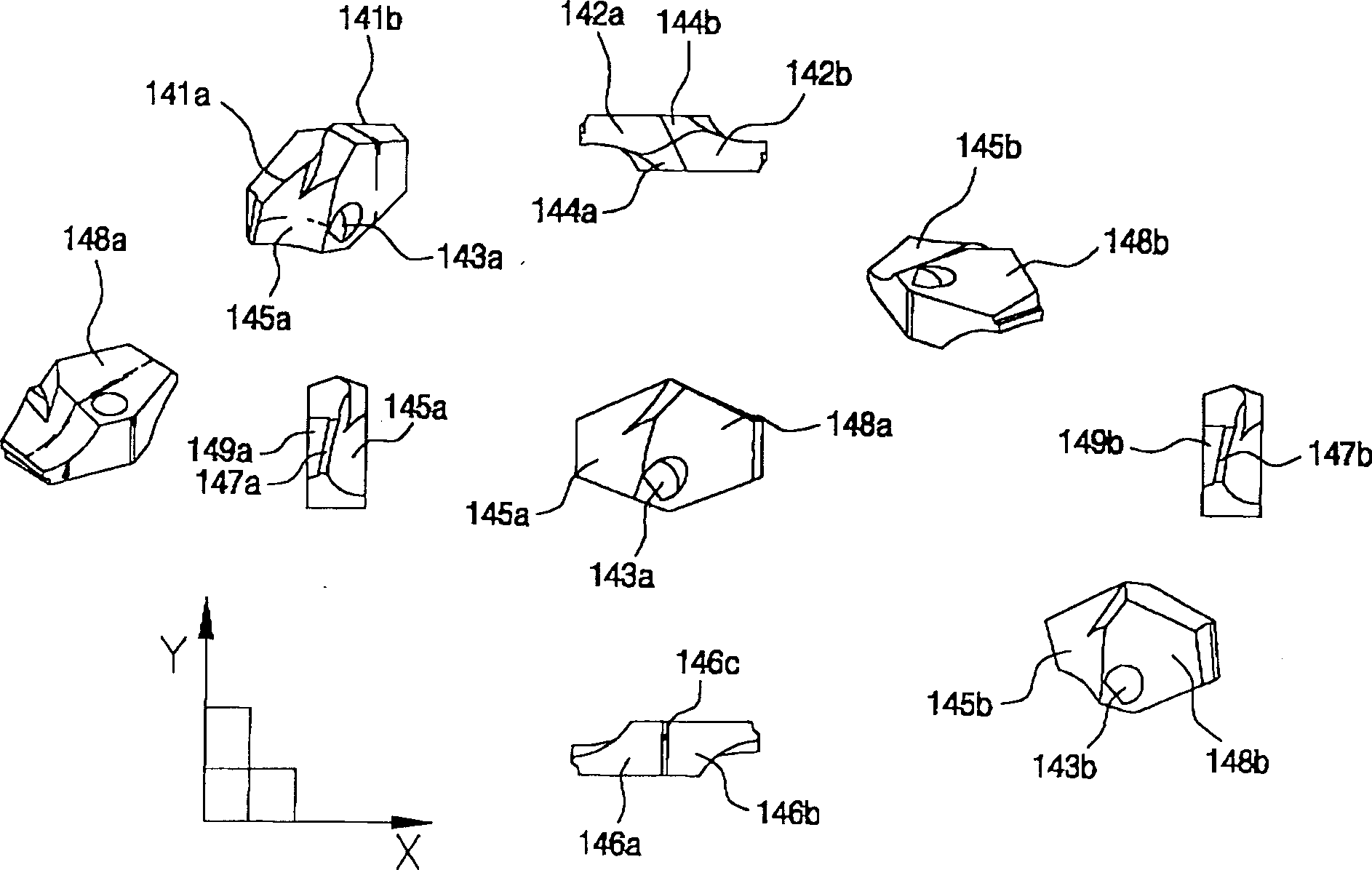

[0019] The drill bit with combined integral insert related to the preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

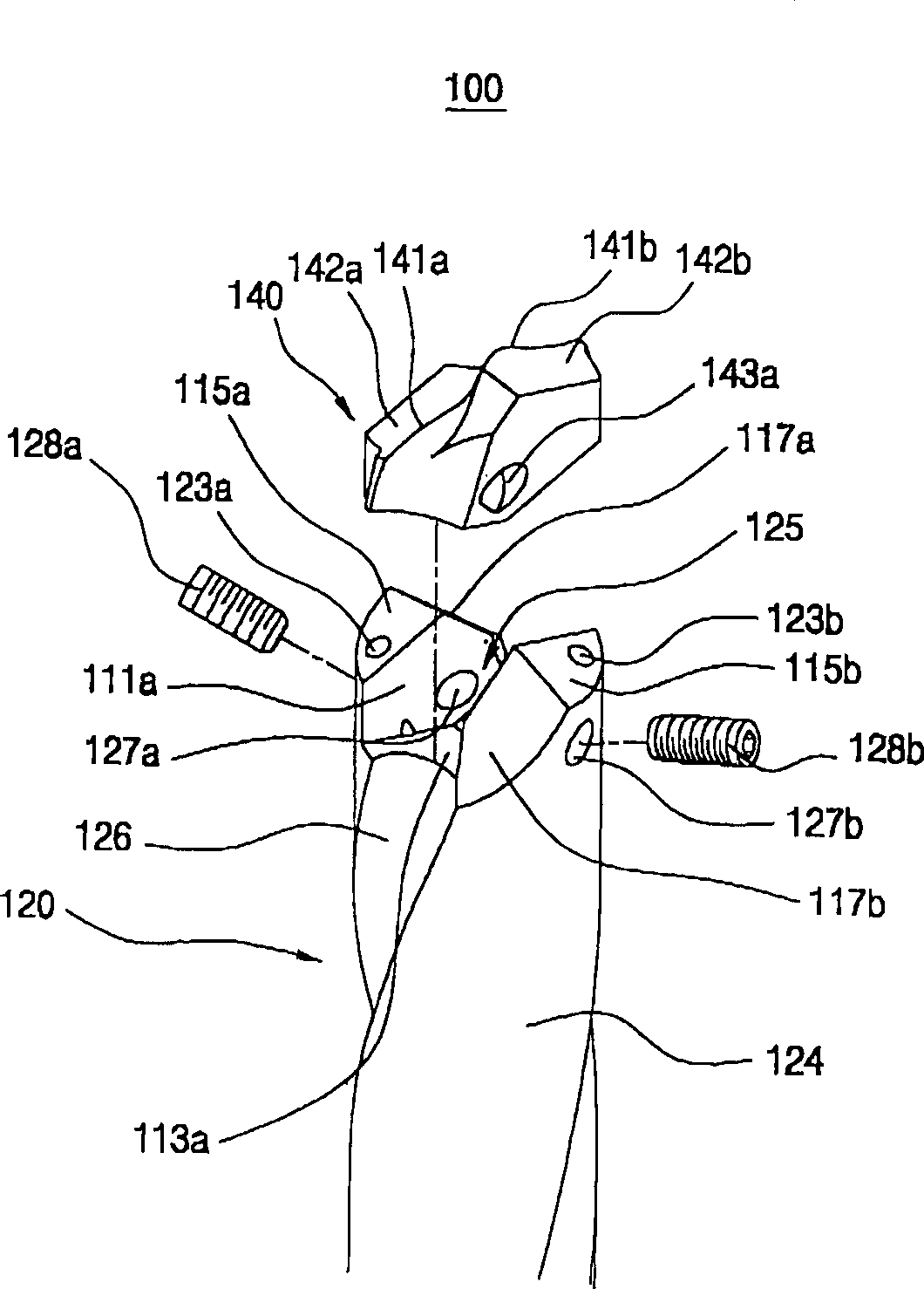

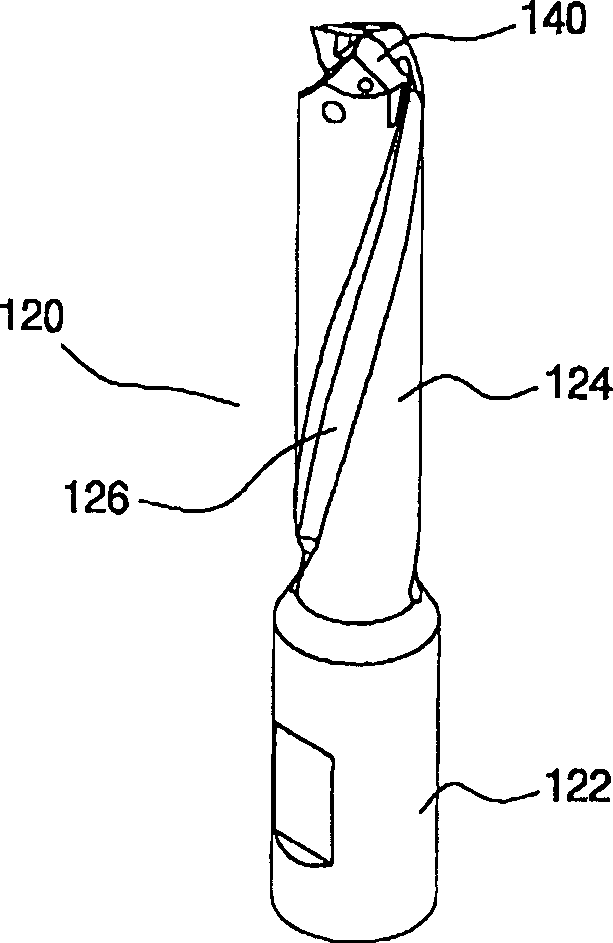

[0020] Such as figure 1 as well as figure 2 As shown, the drill 100 according to the preferred first embodiment of the present invention has a drill body 120 and a drill insert 140 detachably attached to the front end of the drill body 120 .

[0021] The drill body 120 has a shank 122 for fixing the drill to a machine tool (not shown) or a spindle, and a cutting edge 124 extending helically from the shank 122 to the front end of the drill body 120 . On the radially outer side of the cutting edge 124, a spiral groove-shaped flute 126 is formed. A chip flute 126 is formed between the shank 122 and the front end of the drill body 120 for chip discharge and cutting fluid supply.

[0022] Inside the front end of the drill main body 120, an insert base 125 for attaching the drill insert 14...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com