Brake disc type braking system of traction type soil tank experimental platform and braking method of brake disc type braking system

An experimental platform and braking system technology, applied in the field of brake disc brake system, can solve the problem of uncontrolled braking force, etc., to achieve the effect of accelerating heat dissipation, improving operation safety, and smooth braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

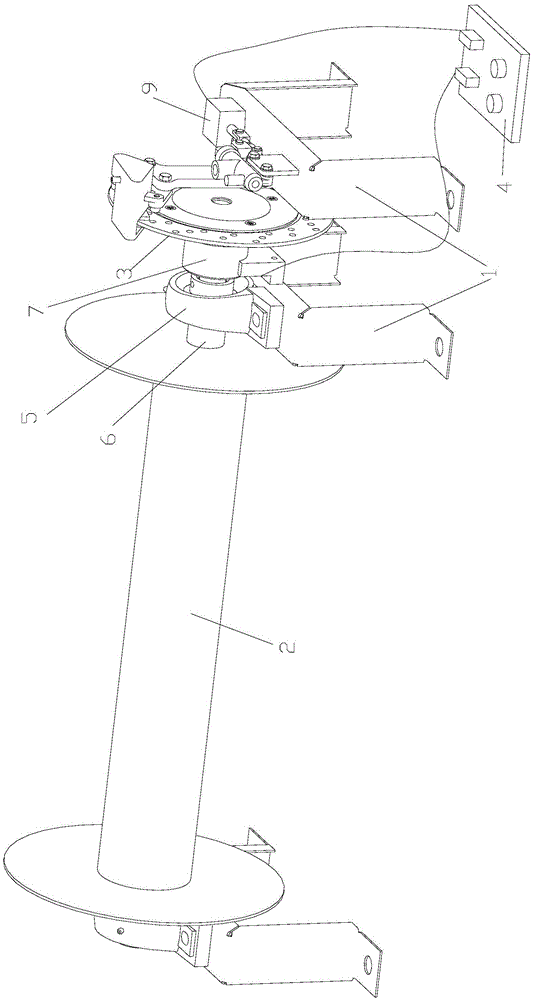

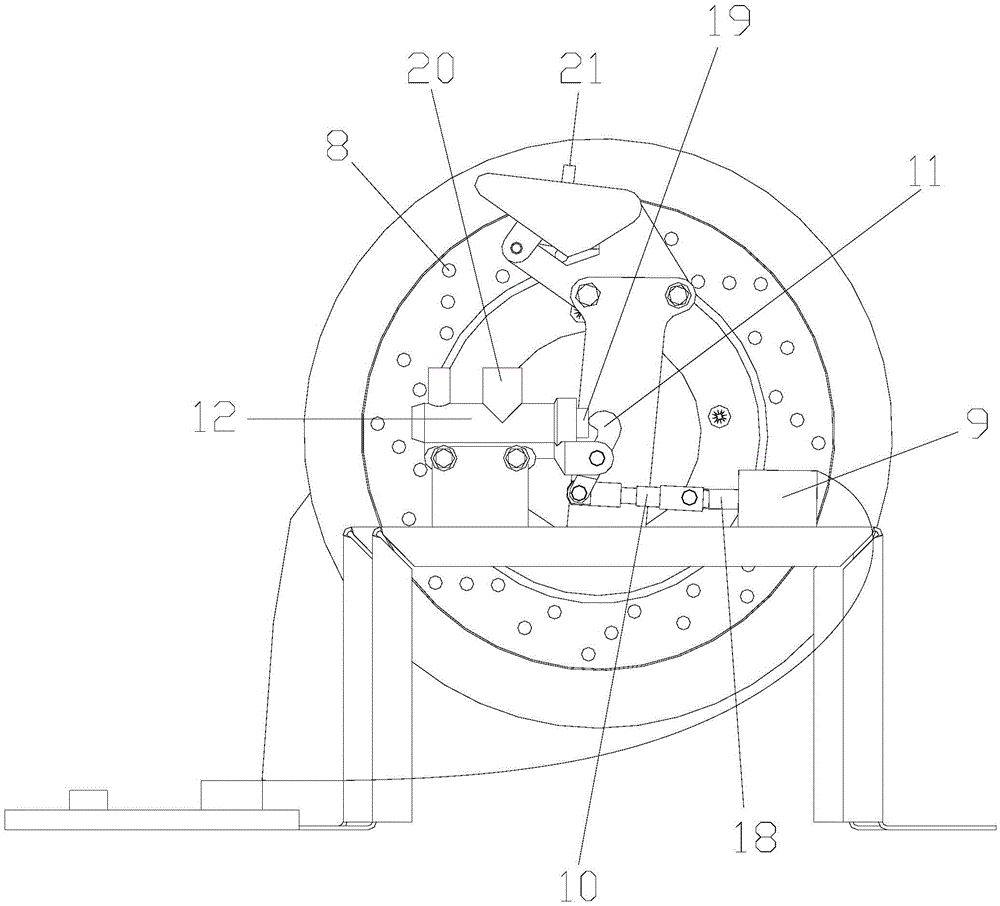

[0022] like figure 1 , figure 2 and image 3 The brake disc brake system of the traction soil tank experimental platform shown includes a frame 1, a traction winding drum 2, a brake disc 3, a brake mechanism and a control module 4,

[0023] The traction winding drum 2 is installed on the frame 1 through the bearing housing 5, and the rotating shaft 6 of the traction winding drum 2 is equipped with a speed measuring instrument 7, and the speed measuring instrument 7 communicates with the control module 4 through a cable, and the speed of the speed measuring instrument 7 The ring rotates synchronously with the rotating shaft 6;

[0024] The brake disc 3 is fixedly installed on one end of the rotating shaft 6, and the brake disc 3 is provided with a plurality of cooling holes 8;

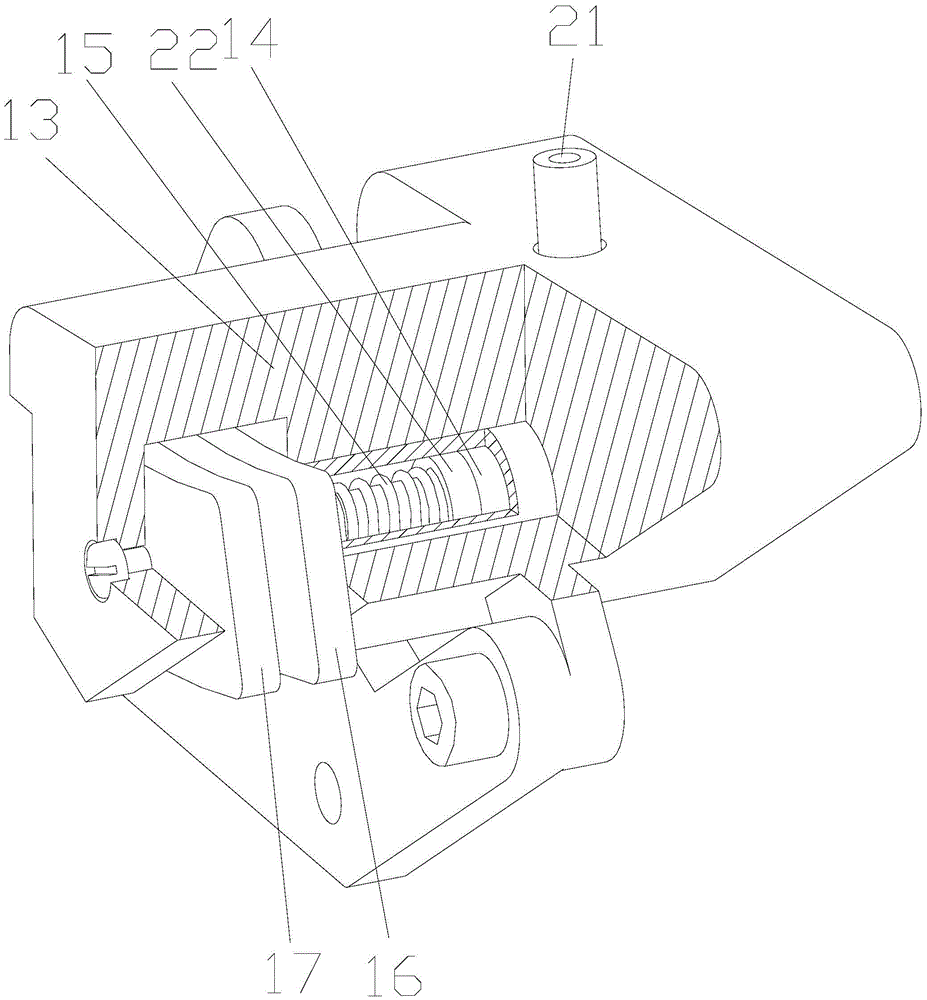

[0025] The brake mechanism includes a linear motor 9, a pull rod 10, a pressure rod 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com