Expansion open hole packer

A packer and open hole technology, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve the problem of high temperature resistance, poor high pressure resistance, expansion type open hole packer wall thickness limit, glue To avoid problems such as cylinder bursting, to improve the effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

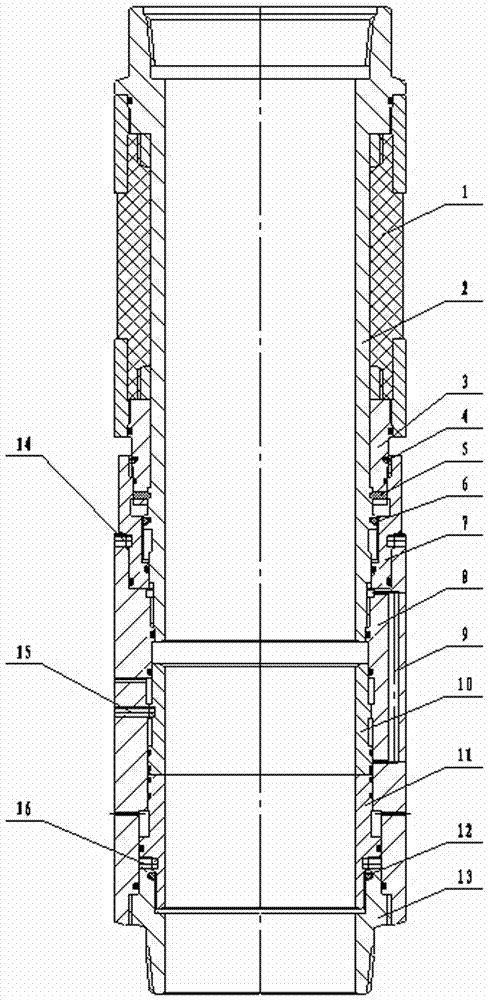

[0020] Expandable open hole packer, including expansion rubber tube 1, central tube 2, rubber tube connecting sleeve 3, upper locking spring 4, clamping block 5, middle locking spring 6, locking sleeve 7, bridge connecting sleeve 8, setting start Sliding sleeve 10, closing and locking sliding sleeve 11, lower locking spring 12, lower joint 13, rubber tube setting pin 14, setting start pin 15, closing locking pin 16. The expansion rubber tube 1 , the rubber tube connecting sleeve 3 and the locking sleeve 7 are sequentially fitted on the outer wall of the central tube 2 . The upper end of the expansion rubber tube 1 is threaded to the central tube 2, and the lower end is screwed to the rubber tube connecting sleeve 3, and the rubber tube connecting sleeve 3 is locked in the groove of the relative central tube 2 by the block 5 installed in the lower groove of the rubber tube connecting sleeve. Inside, the rubber tube connecting sleeve 3 and the central tube 2 are fixed, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com