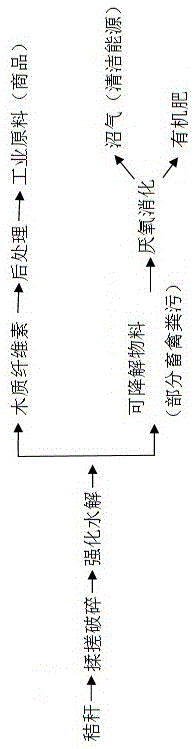

Two-phase anaerobic technology and equipment for extracting lignocellulose from straw and generating methane

A lignocellulose and methane production technology, which is applied in the direction of using microorganism/enzyme cellulose treatment, fiber raw material treatment, biochemical equipment and methods, etc., can solve the problems of difficult maintenance, increased investment, easy failure, etc. The effect of solving problems, solving environmental pollution and increasing capital income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The original Nanjing Ferroalloy Factory in Xiaozhuang Street, Nanjing City carried out a two-phase anaerobic process for extracting lignocellulose and producing methane from straw. The straw used included rice straw, wheat straw and some weeds, totaling 400kg.

[0033]The straw is kneaded and crushed by a kneading crusher, the crushing length is 50-100mm, and the crushing diameter is ≤2mm; the waxy layer crushing rate: ≥80-90%, the surface area of organic matter is increased by 2-3 times, and the non-degradable material crushing size of ≤10mm Amount ≤10-20%. Kneading and crushing can break the waxy layer on the surface of the straw, eliminate the hindrance of the waxy layer, increase the total surface area of the straw, and facilitate subsequent thermal hydrolysis and enhanced hydrolysis and acidification. After kneading and crushing, enter the thermal hydrolysis tank for thermal hydrolysis. The condition of thermal hydrolysis is 60°C and the time is 4 hours. After...

Embodiment 2

[0036] Nanjing Liuhe District Xiongzhou Environmental Protection Equipment Factory conducts a two-phase anaerobic process for extracting lignocellulose and producing methane from straw. The straw used is taken from Longpao Township, Liuhe District, Nanjing, totaling 300kg.

[0037] The straw is kneaded and crushed by a kneading crusher, the crushing length is 50-100mm, and the crushing diameter is ≤2mm; the waxy layer crushing rate: ≥80-90%, the surface area of organic matter is increased by 2-3 times, and the non-degradable material crushing size of ≤10mm Amount ≤10-20%. Kneading and crushing can break the waxy layer on the surface of the straw, eliminate the hindrance of the waxy layer, increase the total surface area of the straw, and facilitate subsequent thermal hydrolysis and enhanced hydrolysis and acidification. After kneading and crushing, enter the thermal hydrolysis tank for thermal hydrolysis. The condition of thermal hydrolysis is 90°C and the time is 1 hour. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crush indicators | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com