Anti-skinning additive for water-based ink, preparation method and application thereof

A water-based ink and anti-skinning technology, which is applied in inks, applications, household appliances, etc., can solve the problems of easy skinning of inks, and achieve the effect of reducing the speed of dirty plates, adding less amount, and reducing water-based inks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

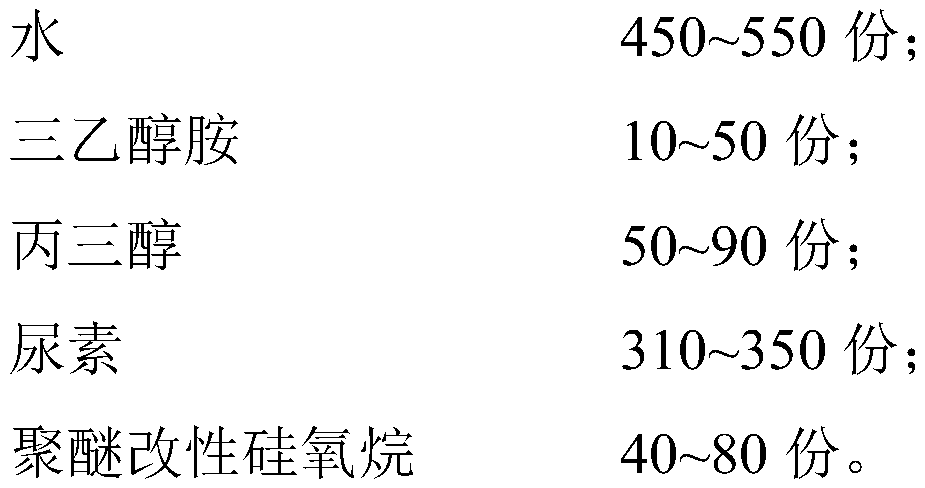

[0035] The present embodiment relates to a kind of anti-skinning auxiliary agent for water-based ink, comprising the following components in parts by weight:

[0036]

[0037] Among them, triethanolamine, glycerin, urea, and polyether modified siloxane are industrial grade raw materials.

[0038] The preparation method is:

[0039] At room temperature, first add 500 parts of water to the material tank, then add 30 parts of industrial grade triethanolamine liquid, and stir for 5 minutes at a medium speed;

[0040] In the stirring state, slowly add 80 parts of industrial grade glycerol liquid into the material tank, and continue to stir for 5 minutes;

[0041] In the stirring state, continue to slowly add 340 parts of industrial grade urea solids into the material tank, and then stir for 5 minutes;

[0042] Slowly add 50 parts of industrial-grade polyether-modified siloxane, and then stir at a medium speed for 10 minutes to disperse all the raw materials evenly, and then th...

Embodiment 2

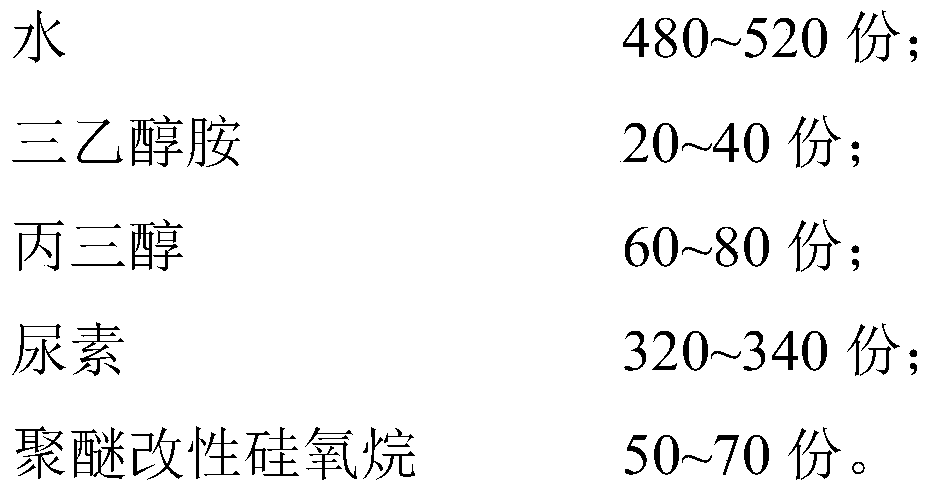

[0048] The present embodiment relates to a kind of anti-skinning auxiliary agent for water-based ink, comprising the following components in parts by weight:

[0049]

[0050] Among them, triethanolamine, glycerin, urea, and polyether modified siloxane are industrial grade raw materials.

[0051] The preparation method is:

[0052] At room temperature, first add 520 parts of water to the material tank, then add 10 parts of industrial grade triethanolamine liquid, and stir for 5 minutes at a medium speed;

[0053] In the stirring state, slowly add 60 parts of industrial grade glycerol liquid into the material tank, and continue to stir for 5 minutes;

[0054] In the stirring state, continue to slowly add 350 parts of industrial grade urea solids into the material tank, and then stir for 5 minutes;

[0055] Slowly add 60 parts of industrial-grade polyether-modified siloxane, and then stir at a medium speed for 10 minutes to disperse all the raw materials evenly, and then pr...

Embodiment 3

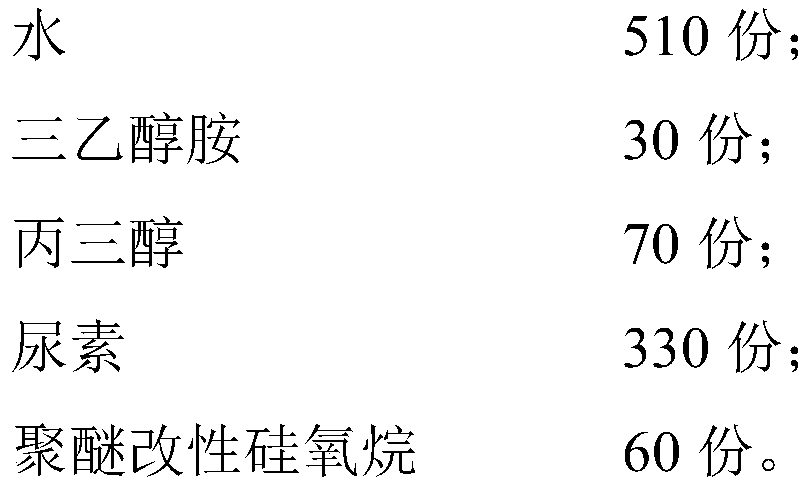

[0061] This embodiment relates to a kind of anti-skinning auxiliary agent for water-based ink, comprising the following components by weight:

[0062]

[0063] Among them, triethanolamine, glycerin, urea, and polyether modified siloxane are industrial grade raw materials.

[0064] The preparation method is:

[0065] At room temperature, first add 510 parts of water to the material tank, then add 30 parts of industrial grade triethanolamine liquid, and stir for 5 minutes at a medium speed;

[0066] In the stirring state, slowly add 70 parts of industrial grade glycerol liquid into the material tank, and continue to stir for 5 minutes;

[0067] In the stirring state, continue to slowly add 330 parts of industrial grade urea solids into the material tank, and then stir for 5 minutes;

[0068] Slowly add 60 parts of industrial-grade polyether-modified siloxane, and then stir at a medium speed for 10 minutes to disperse all the raw materials evenly, and then prepare the anti-ski...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com