Lifting and walking type storage battery van

A technology for batteries and trucks, applied in the direction of lifting devices, etc., can solve the problems of battery life limitation, increase the cost of large-scale equipment, and bottlenecks in the development of electric forklifts, and achieve the effect of simplifying replacement steps, satisfying convenience, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

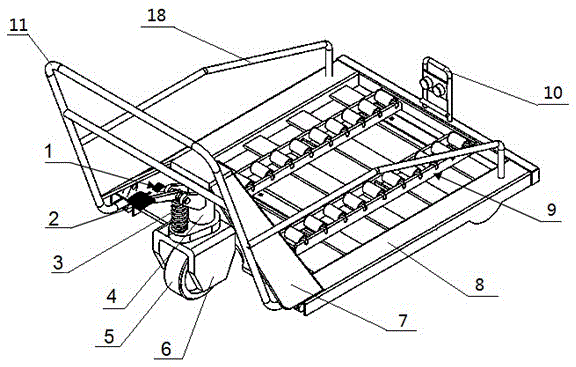

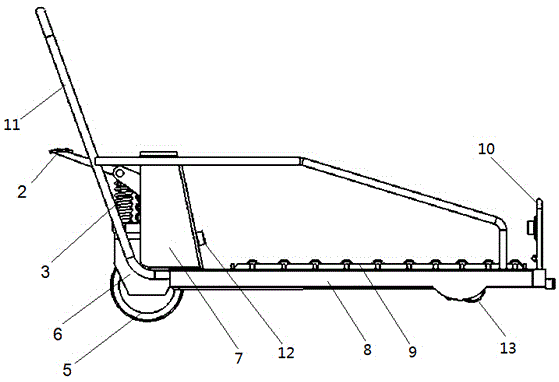

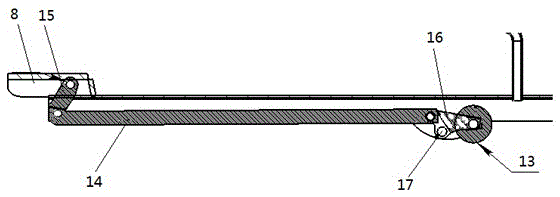

[0026] Such as figure 1 , 2 As shown in , 3, a kind of hoisting and walking type storage battery truck comprises a car body floor 8, the bottom of the car body floor 8 is provided with front wheels 13 and rear wheels 5, and the rear end of the car body floor 8 is fixed vertically A rear plate 7 is provided, and two roller brackets 9 are symmetrically fixed on the top surface of the vehicle body floor 8, and rollers are uniformly arranged on the roller brackets 9; the top of the rear plate 7 is connected with the hydraulic device 4; The front and rear bottom ends of the vehicle body floor 8 are respectively connected with the triangular connecting rod 16 and the short connecting rod 15 through a rotating shaft, and the second end of the triangular connecting rod 16 is connected with the main shaft of the front wheel 13 through a rotating shaft. The third end of the rod 16 is connected to the short connecting rod 15 through the long connecting rod 14 .

[0027] In a further so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com