Rapid shaping device and method based on ultraviolet exposed dynamic mask plate technology

A mask and ultraviolet light technology, applied in the direction of additive processing, etc., can solve the problems of difficult to increase the life of the mask, small collision probability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

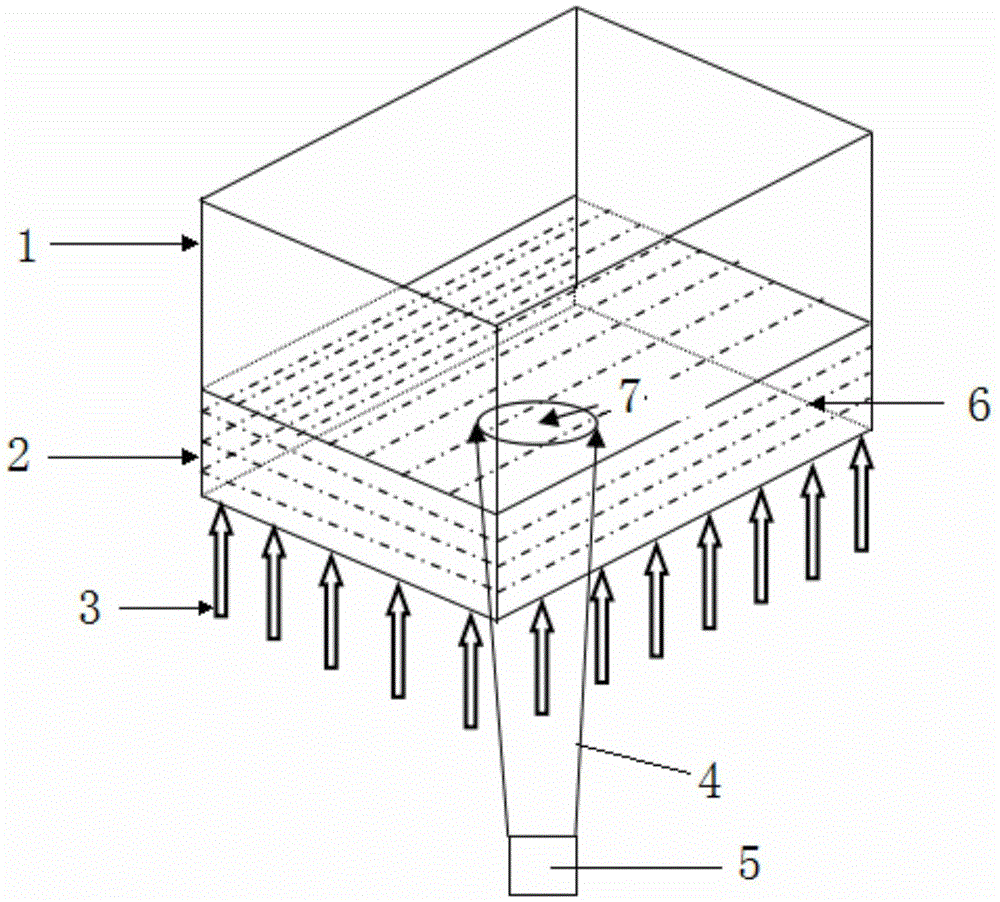

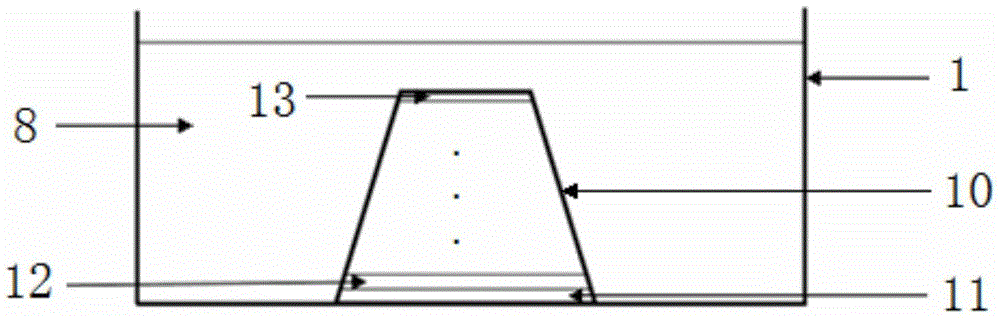

[0029] Such as figure 1 As shown, the rapid prototyping device based on the ultraviolet exposure dynamic mask technology includes a resin tank 1, a closed air chamber 2, a long-wave ultraviolet light source, a short-wave ultraviolet light source and a control host 5. The closed air chamber 2 is set in the resin tank 1 Below, the light emitted by the long-wave ultraviolet light source and the short-wave ultraviolet light source is incident into the resin tank 1 through the closed air chamber, and the liquid photosensitive resin is housed in the resin tank 1, and can be cured under the irradiation of long-wave ultraviolet light 3; Oxygen 6 is housed in the enclosed air chamber, and the short-wave ultraviolet light source projects short-wave ultraviolet light 4 to the oxygen in the enclosed air chamber according to the specific shape of the forming and processing layered slices, making it react to generate ozone, and making the enclosed air chamber 2 The local projection area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com