Method for welding main steam or main water supply pipeline of nuclear island in nuclear power plant

A welding method and main steam technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of high labor intensity, easy injury of welders, low efficiency, etc., to achieve good welding seam forming quality and reduce welding material consumption. , the effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

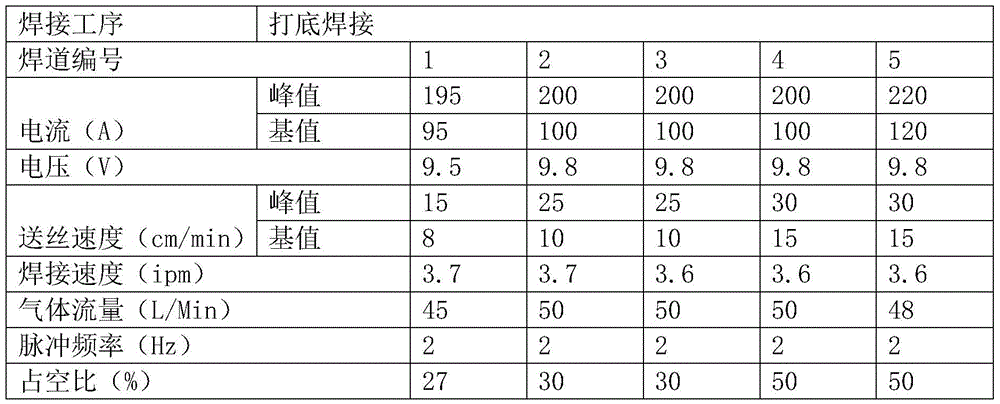

[0043] The welding equipment adopts LIBRUDIGT-VI automatic welding machine, the welding wire model is ER70S-6, the welding wire diameter is 1.0mm, the shielding gas is argon, the purity of the shielding gas is ≥99.99%, the tungsten pole is cerium tungsten pole, and the diameter of the tungsten pole is 3.2mm. The welding position is 5GT, and the specification of the main steam pipe of the nuclear island is The main steam pipe of the nuclear island is made of P280GH alloy steel.

[0044] The welding method of the main steam or main water supply pipeline of the nuclear power plant nuclear island of the present embodiment comprises the following steps:

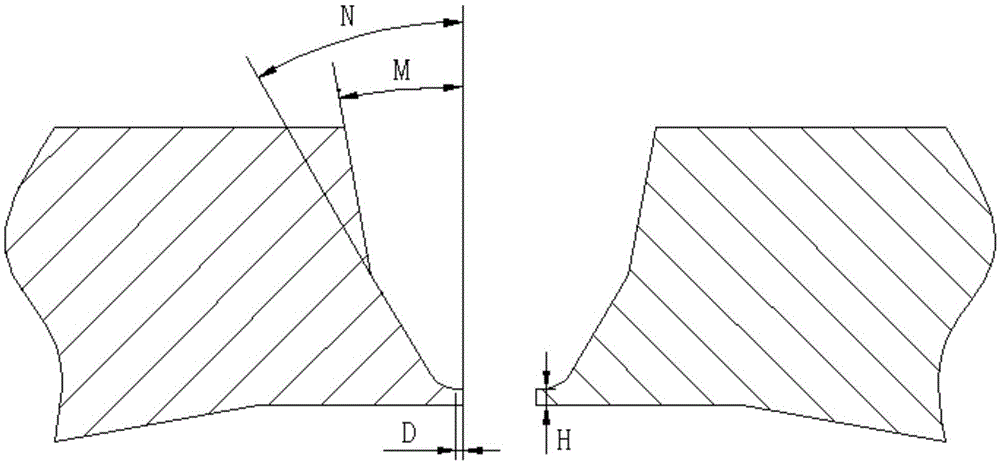

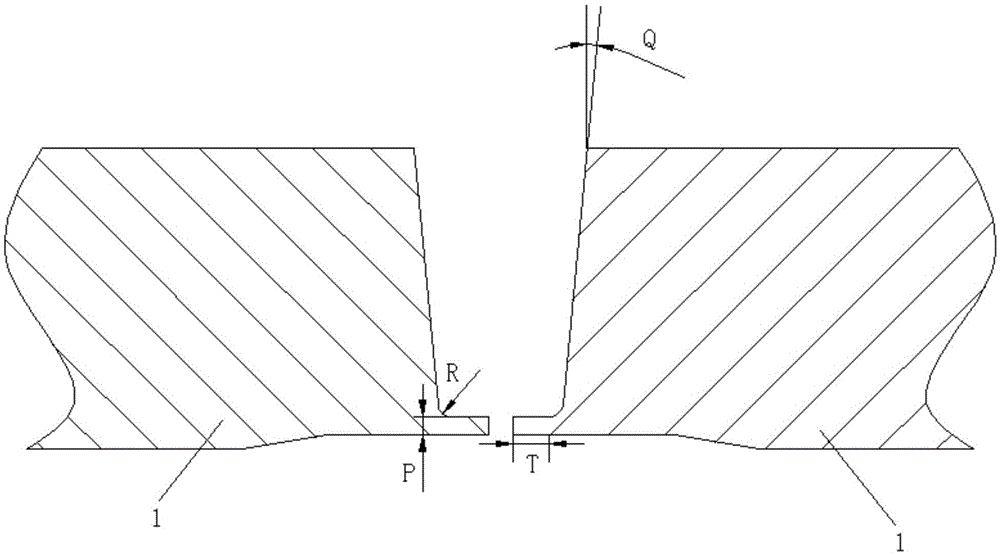

[0045] (1) The groove of the main steam pipe of the nuclear island is machined with a groove machine. The finished groove is a U-shaped groove, and the groove angle Q of the groove is 7°, the length T of the blunt side is 2mm, and the blunt side The thickness P is 2mm, and the chamfer radius R is 2mm.

[0046] After the groove ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com