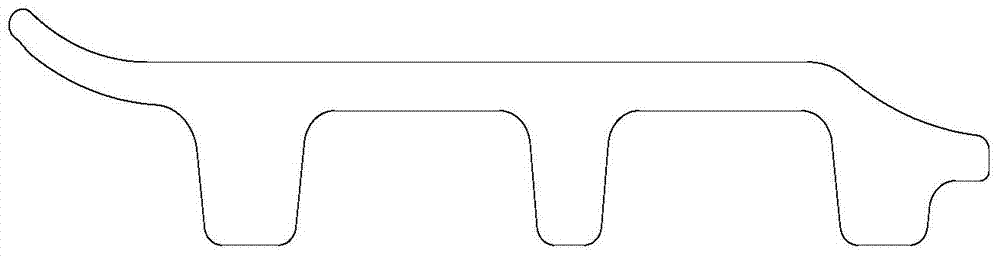

Roughing mill pass system for hot rolling track shoes and hot rolling method for track shoes

A rough rolling mill and crawler shoe technology, applied in metal rolling and other directions, can solve the problems of complex shape of crawler shoe, low degree of automation, uneven deformation, etc., and achieve the effect of eliminating limitations and unfavorable conditions, promoting widening and increasing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

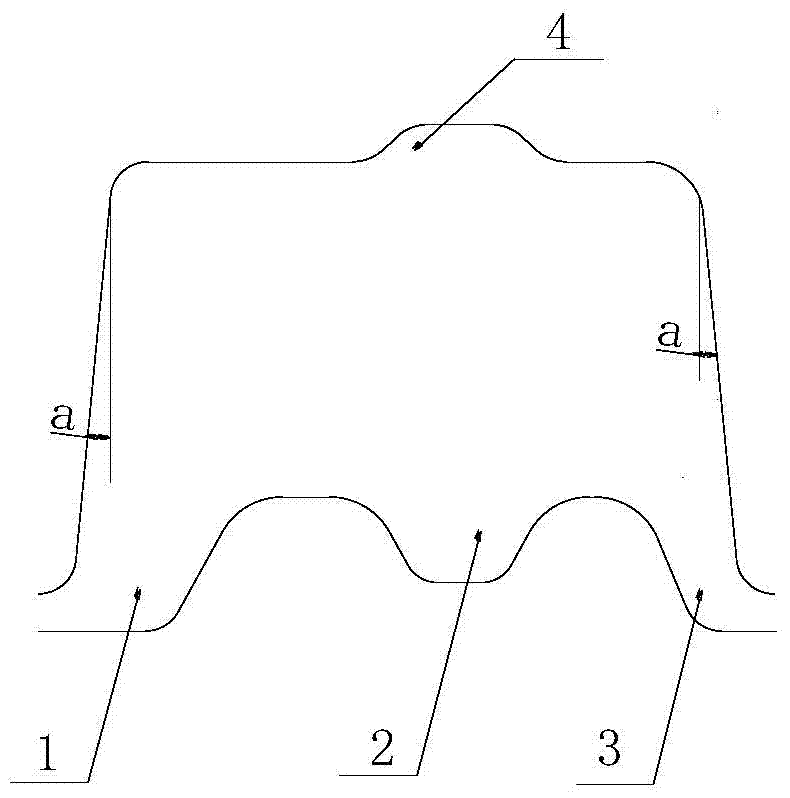

[0037] A hot-rolling process for track shoes. The rough rolling adopts a three-roll rolling mill, and the ratio of the height to the width of the billet is 1; each rough rolling hole is provided with three legs; above the pass, there is a false leg corresponding to the middle leg; The rolling passes are composed of leg height increasing holes and wing plate widening holes.

[0038] The two side legs (the first side leg 1 and the second side leg 3) of each rough rolling hole are equal in height, and the middle leg 2 is 60% of the height of the side legs.

[0039] The artificial leg 4 is located directly above the middle leg 2, has a width similar to that of the middle leg, and a height of 10mm.

[0040] The shape of the leg height increasing hole is roughly E-shape with the opening downward, the top sides of the leg height increasing hole are inclined outwards, the angle a with the vertical direction is 5°, and the opening of the hole is downward.

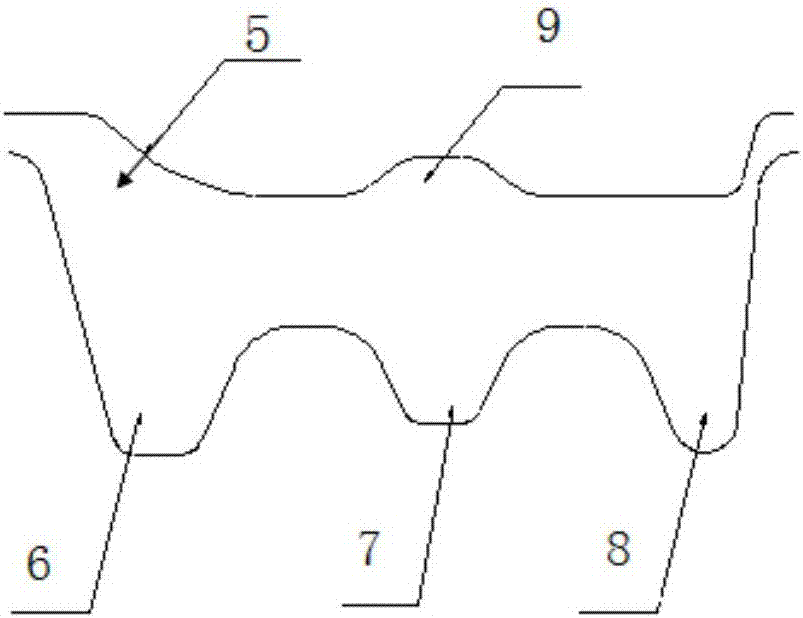

[0041] The wing plate 5 of ...

Embodiment 2

[0046] A hot-rolling process for track shoes. The rough rolling adopts a three-roll rolling mill, and the ratio of the height to the width of the billet is 0.8; each rough rolling hole is provided with three legs; above the pass, there is a false leg corresponding to the middle leg; The rolling passes are composed of leg height increasing holes and wing plate widening holes.

[0047] The two side legs (the first side leg 1 and the second side leg 3) of each rough rolling hole are equal in height, and the middle leg 2 is 90% of the height of the side legs.

[0048] The artificial leg 4 is located directly above the middle leg 2, has a width similar to that of the middle leg, and a height of 20 mm.

[0049] The shape of the leg height increasing hole is roughly E-shape with the opening downward, the top sides of the leg height increasing hole are inclined outwards, the angle a with the vertical direction is 20°, and the opening of the hole is downward.

[0050] The wing plate 5 o...

Embodiment 3

[0055] A hot-rolling process for track shoes. The rough rolling adopts a three-roll rolling mill, and the ratio of the height to the width of the billet is 0.6; each rough rolling hole is provided with three legs; above the pass, there is a false leg corresponding to the middle leg; The rolling passes are composed of leg height increasing holes and wing plate widening holes.

[0056] The two side legs (the first side leg 1 and the second side leg 3) of each rough rolling hole are equal in height, and the middle leg 2 is 70% of the height of the side legs.

[0057] The artificial leg 4 is located directly above the middle leg 2, has a width similar to that of the middle leg, and a height of 30 mm.

[0058] The shape of the leg height increasing hole is roughly E-shape with the opening downward, the top sides of the leg height increasing hole are inclined outwards, the angle a with the vertical direction is 10°, and the opening of the hole is downward.

[0059] The wing plate 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com