A method of predicting impeller flutter

A technology of impeller and flutter, which is applied in special data processing applications, instruments, electrical digital data processing, etc. It can solve the problems of inability to predict the stability of milling processing, and does not consider the change of workpiece transfer function, so as to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

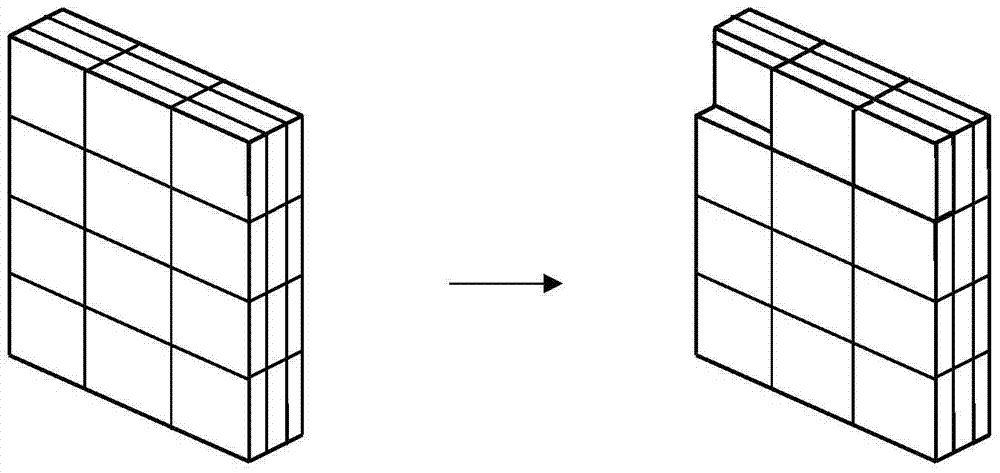

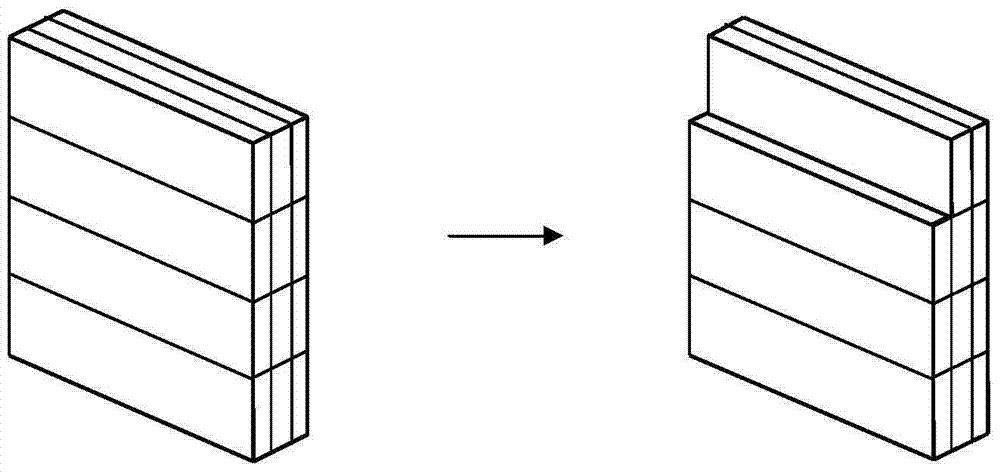

[0040] In this embodiment, the impeller of titanium alloy TC4 is taken as an example. The selected cutting conditions are: the spindle speed is 800rpm, the feed speed is 96mm / min, the cutting depth is 1mm, and the length of the clamping part of the impeller workpiece is 30mm. Choose a ball end milling cutter, semi-contact up milling method, and take 15mm as the axial length of a processing sub-stage in the axial direction of the milling cutter.

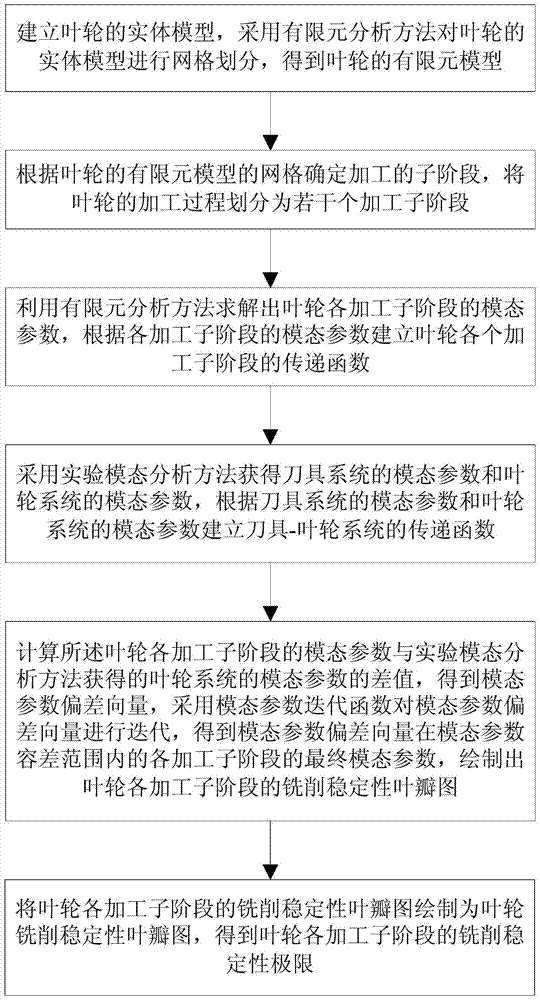

[0041] A method for predicting impeller flutter, such as figure 1 shown, including the following steps:

[0042] Step 1: Establish a solid model of the impeller, use the finite element analysis method to mesh the solid model of the impeller, and obtain the finite element model of the impeller.

[0043] In this embodiment, CAD is used for solid modeling of the impeller. Generally, for thin-walle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com