Sample measuring cell

A technology for measuring cells and samples, applied in measuring devices, material analysis through optical means, instruments, etc., can solve problems such as inability to adapt to the measurement environment, limited compactness, and reduced reflectivity of high-reflection coatings, and achieve environmental adaptability Long optical path, strong environmental adaptability, and improved environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

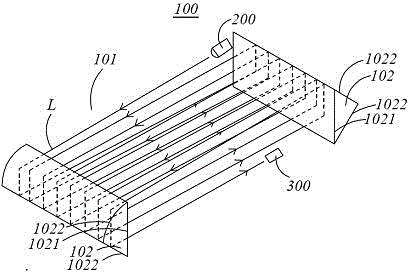

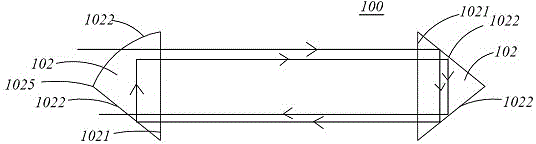

[0031] Such as figure 1 and figure 2 As shown, in one embodiment of the present invention, the sample measurement cell 100 includes a reflective cavity 101 and at least one reflective structure 102; the reflective cavity 101 is used to accommodate the sample to be measured, and the at least one reflective structure 102 is arranged The boundary of the reflective cavity 101; wherein, the reflective structure 102 includes at least one contact surface 1021 and two reflective surfaces 1022, the contact surface 1021 contacts the sample to be measured, and the reflective surface 1022 is away from the sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com