Multi-gear automatic transmission

An automatic transmission and gear technology, which is applied in the field of automobile transmission system, can solve the problems of large overall transmission range, complex bearing arrangement, increase the difficulty of oil circuit design and manufacturing cost, etc., and achieve the effect of excellent gear ratio sequence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

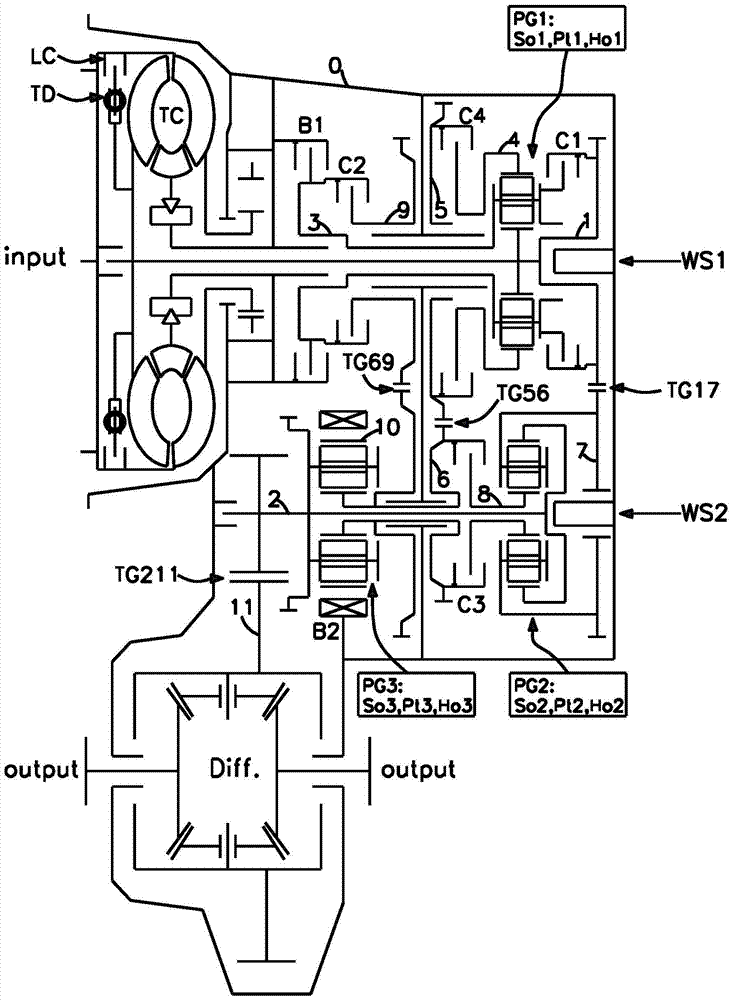

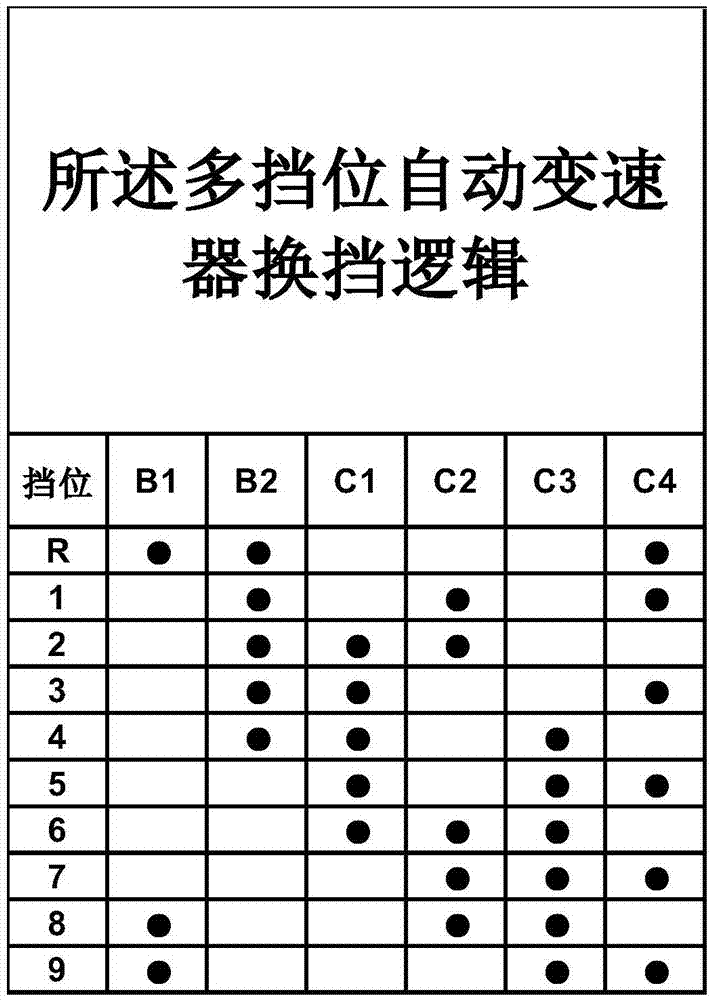

[0057] Such as figure 1 As shown, a multi-speed automatic transmission can realize nine forward gears and one reverse gear. It includes two shaft systems WS1 and WS2 arranged in parallel. The input shaft input is connected to the first shaft of the first shaft system WS1 through the torque converter TC with torsional shock absorber TD and lock-up clutch LC, and the second shaft of the second shaft system WS2 is through the final reduction gear set TG211 Drive the differential gear Diff., and then transmit it to the wheels on both sides through the output terminals on both sides of the differential gear.

[0058] The first axis system is located on the active side, including the first axis 1, the third axis 3, the fourth axis 4, the fifth axis 5, and the ninth axis 9. The second shaft system is located on the driven side and includes a second shaft 2 , a sixth shaft 6 , a seventh shaft 7 , an eighth shaft 8 , and a tenth shaft 10 .

[0059] The ninth shaft 9 and the sixth sh...

no. 2 example

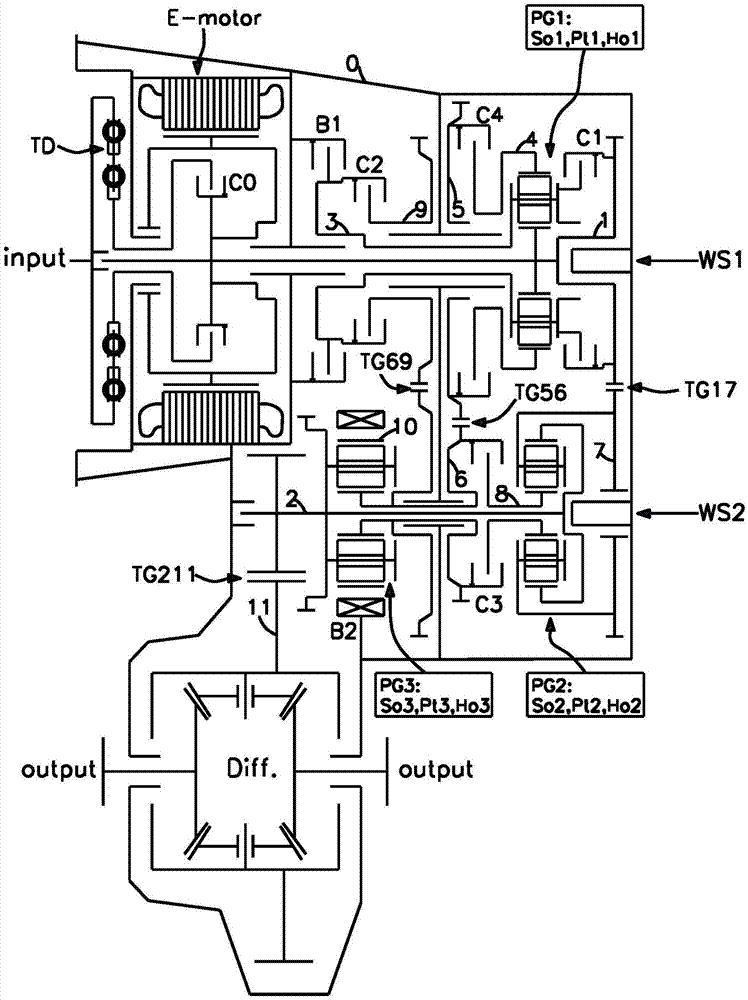

[0090] The second example is figure 2 Shown is another application of the multi-speed automatic transmission of the first embodiment, which is called a hybrid power transmission scheme. The structure of the second embodiment is basically the same as that of the first embodiment, except that the torque converter TC is replaced by an electric motor E-motor. The motor is directly connected to the first shaft of the multi-speed automatic transmission, and an additional clutch C0 is integrated and arranged inside the motor. The clutch C0 is used to cut off and connect the engine, and its two sides are the input shaft input and the first shaft respectively. When the vehicle starts or runs at a low speed, the clutch C0 is opened, and only the motor drives the transmission system. When the power demand of the vehicle is high, such as high-speed driving conditions, the clutch C0 is closed and connected to the engine, so that the power output by the engine can drive the vehicle trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com