Method for generating electricity by means of low temperature exhaust heat of power plant

A low-temperature waste heat and power plant technology, applied in hydropower, engine components, machines/engines, etc., can solve problems such as not having the advantage of water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

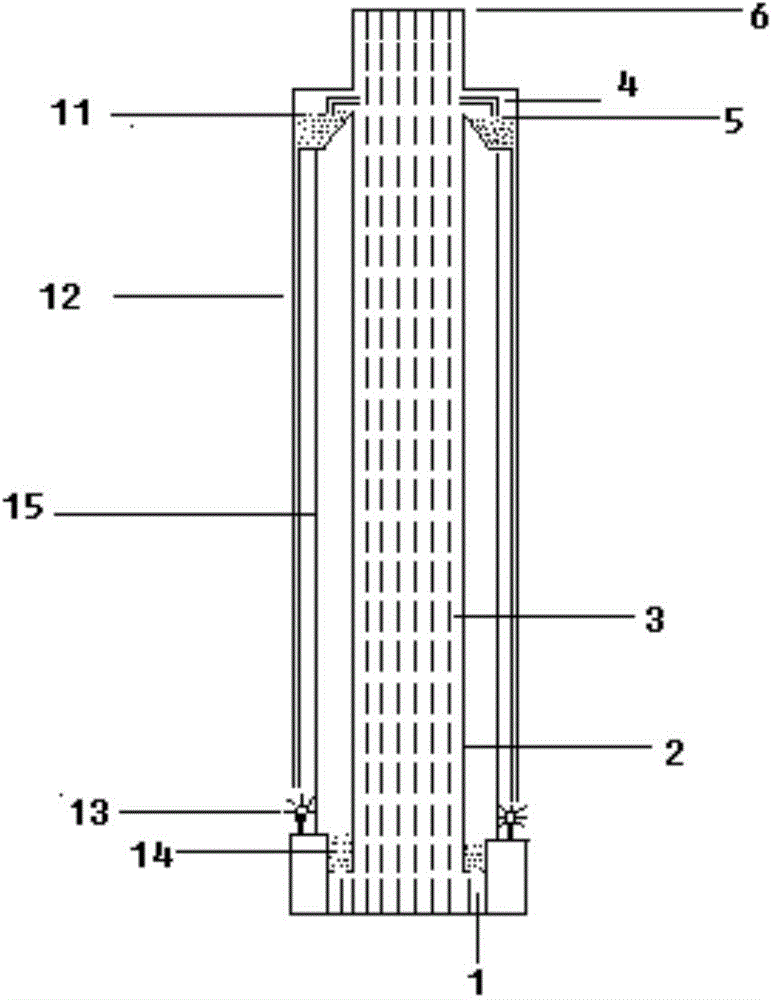

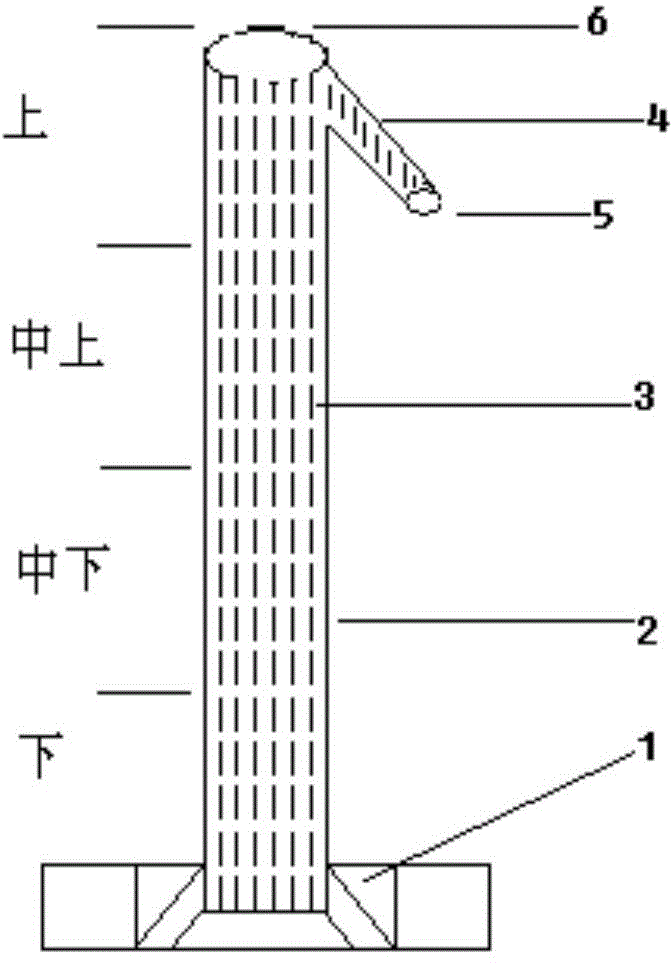

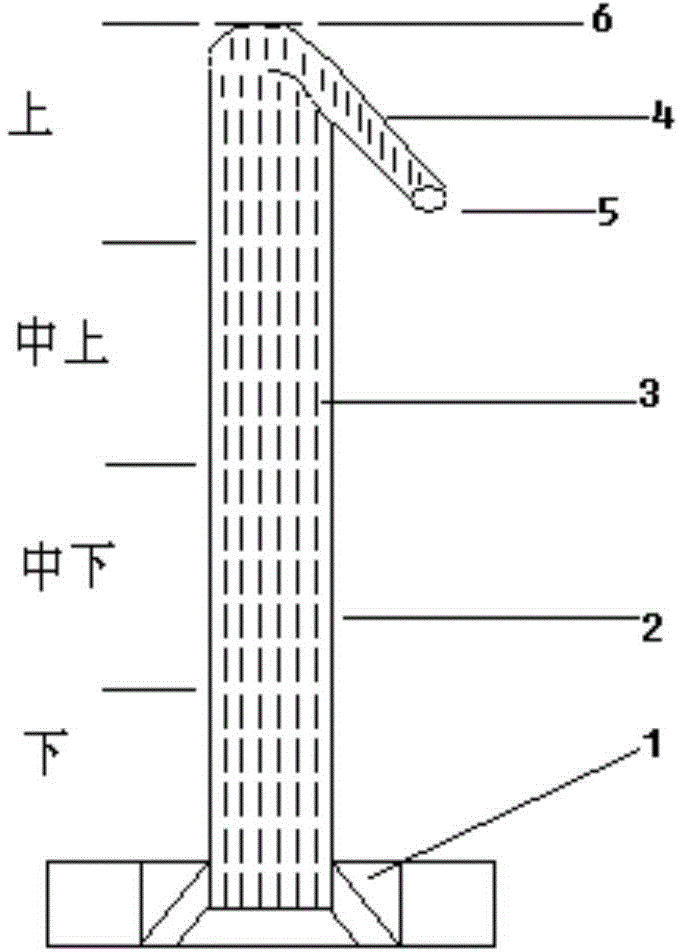

[0066] to attach figure 1 As an implementation example to illustrate:

[0067] figure 1 It is a schematic diagram of the power generation structure of the "water upward flow" equipment, in which 1 is the immersion body, 2 is the outer casing of the pipe, 3 is the capillary pipe inside the pipe, 4 is the water outlet of the pipe, 5 is the water outlet, 6 is the top horizontal line, 11 is 12 is the drop between the high reservoir and the water turbine, 13 is the water turbine, 14 is the waste heat water of the power plant, and 15 is the supporting structure of the high reservoir. As the name implies, the submerged body (1) is the part soaked in water, including the part of the outer shell of the pipe (2) soaked in water and the part of the inner capillary (3) soaked in water.

[0068] The water (14) with waste heat from the power plant is pumped to the high-level storage tank (11) through the equipment with the function of "water flowing upward", and there is a drop between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com