Dry type sewage pump

A sewage pump, dry-type technology, applied in the direction of non-variable pumps, non-volume pumps, pumps, etc., can solve the problems of inconvenient movement, manual start and stop, etc., to achieve convenient movement, improve market competitiveness, reduce The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

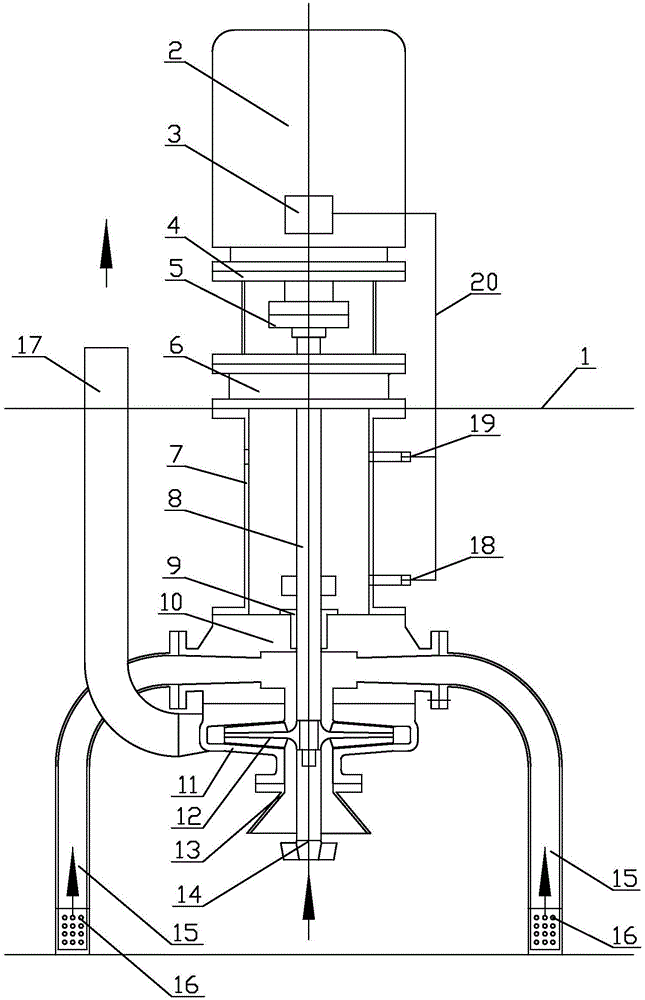

[0038] figure 1 It is a schematic diagram of the structure of the dry sewage pump of the present invention, such as figure 1 As shown, the dry sewage pump includes a motor 2, a controller 3, a motor bracket 4, a coupling 5, a bearing chamber 6, a support cylinder 7, a pump shaft 8, a bearing 9, a pump cover 10, a pump body 11, and an impeller 12. , Suction bell 13, agitator 14, water inlet pipe 15, filter 16, water outlet pipe 17, lower liquid level gauge 18, upper liquid level gauge 19 and signal line 20.

[0039] The dry sewage pump is driven by the motor 2 through the coupling 5 and the pump shaft 8 to rotate the impeller 12, sucking sewage into the pump body 11 from the suction bell 13 and the inlet pipe 15. The impeller 12 transfers kinetic energy to the sewage, so that the pot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com