A top bolt drilling rig and a top bolt drilling rig comprising the same

A technology for top anchor and drilling rig, which is used in the installation of anchor rods, drilling equipment, and earth-moving drilling and mining, etc., can solve the problems of low degree of mechanization, low efficiency and high labor intensity of the single-piece rock-bolt drill. , to solve the contradiction of excavation and anchor imbalance, compact structure and high drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Embodiment 1: The specific structure of the four-arm top bolter rig comprising the above-mentioned top bolter rig is as follows:

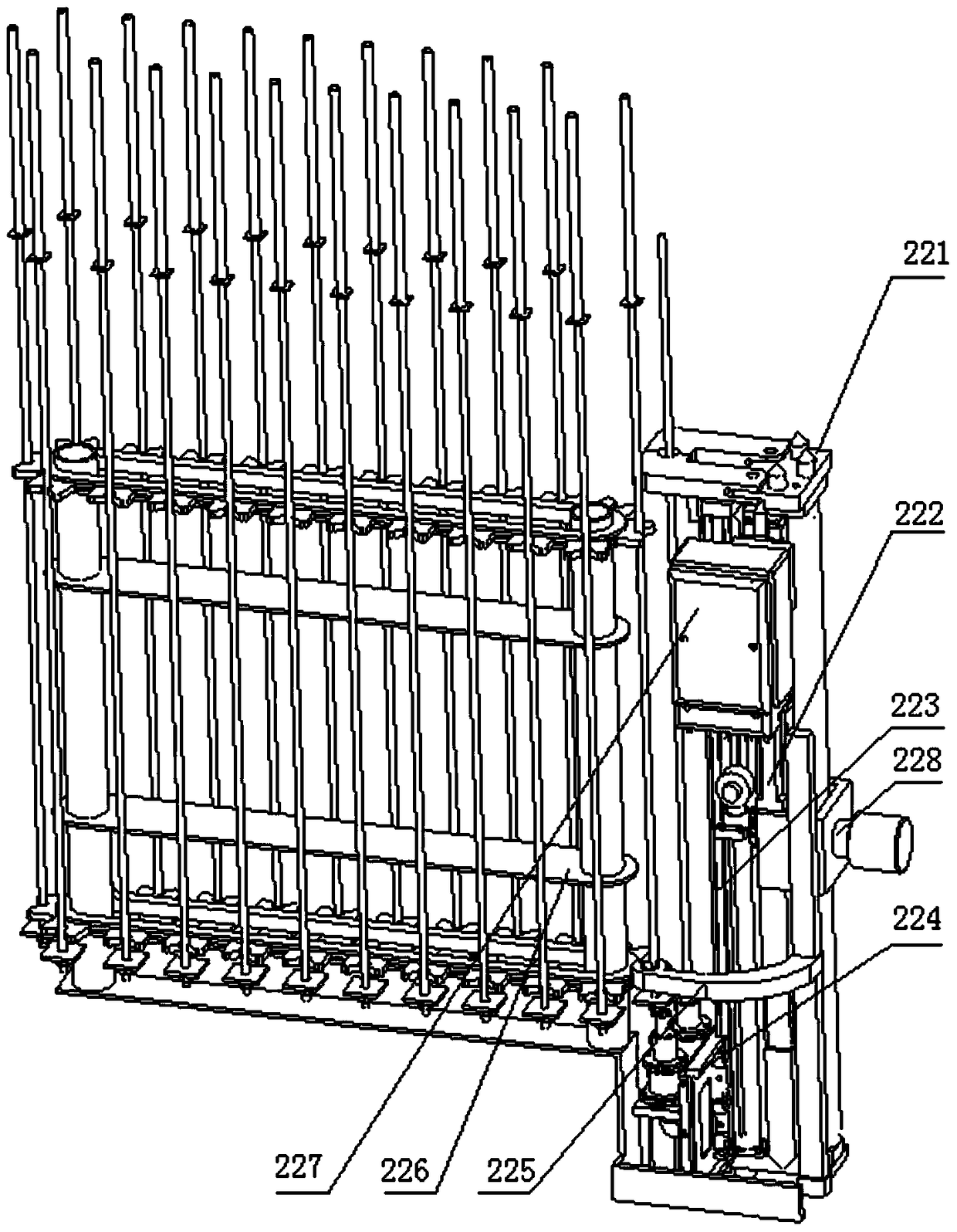

[0070] Refer to attached Figure 6 and 7 As shown, the four-arm top bolt drilling rig includes a self-propelled mechanism 7, a body part 4, a drilling arm mechanism 2, a control mechanism 6, a storage and delivery mechanism 5, a supporting and laying mechanism 1, and an electrical and hydraulic system 3 .

[0071] The self-propelled mechanism 7 is a crawler-type traveling mechanism, which is located at the bottom of the drilling rig, and includes a tightening oil cylinder, a traveling motor and a speed reducer. The tension of the track can be adjusted through the telescopic movement of the tension cylinder; the travel motor drives the reducer, and the track is driven by the sprocket to realize the forward and backward movement of the walking mechanism. The self-propelled mechanism 7 is controlled by the control mechanism 6, and can achiev...

Embodiment 2

[0081] Embodiment 2: The six-arm top bolter comprising the above-mentioned top bolter is further improved on the basis of the above-mentioned four-arm top bolter, and its improvements are as follows:

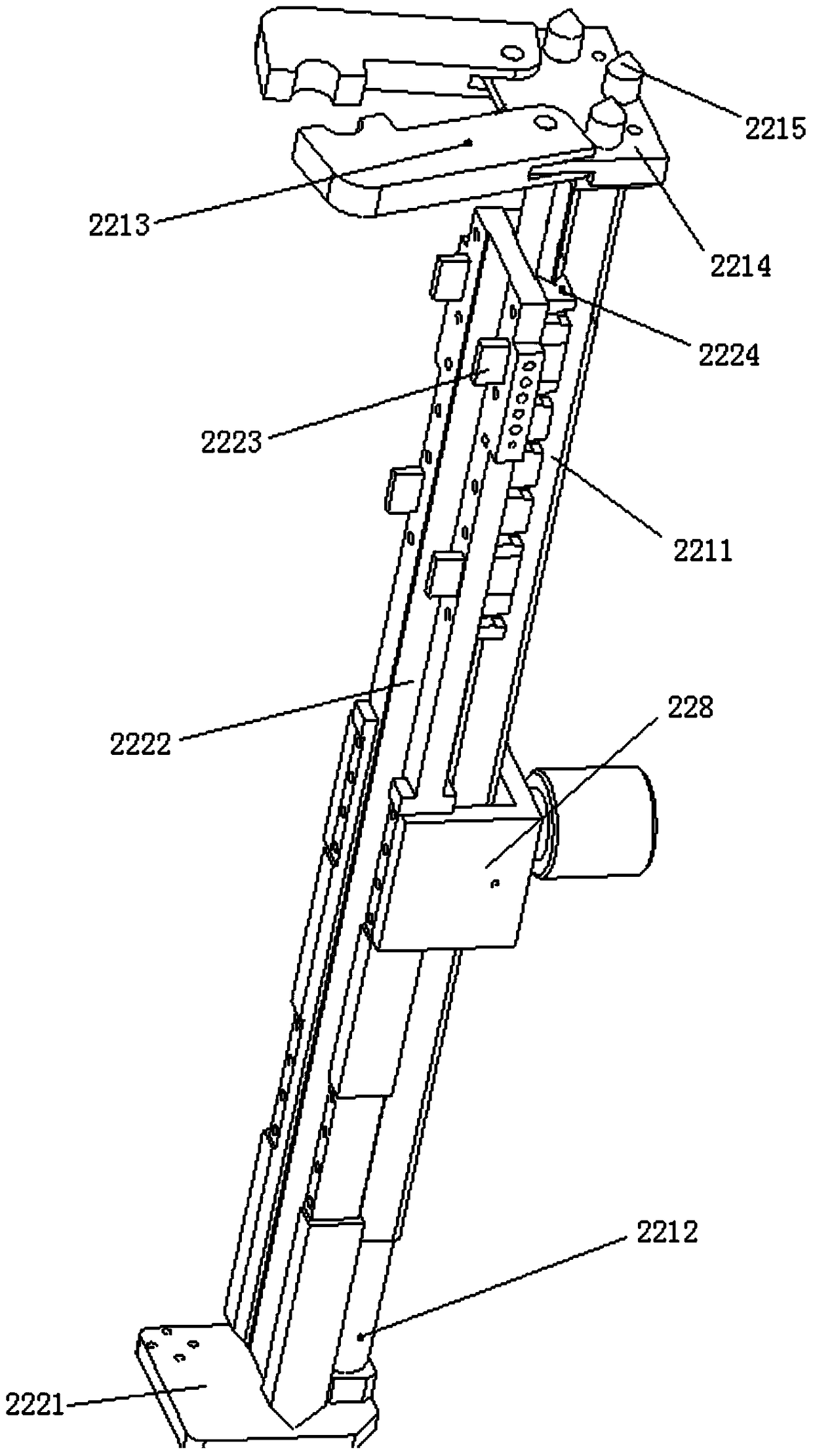

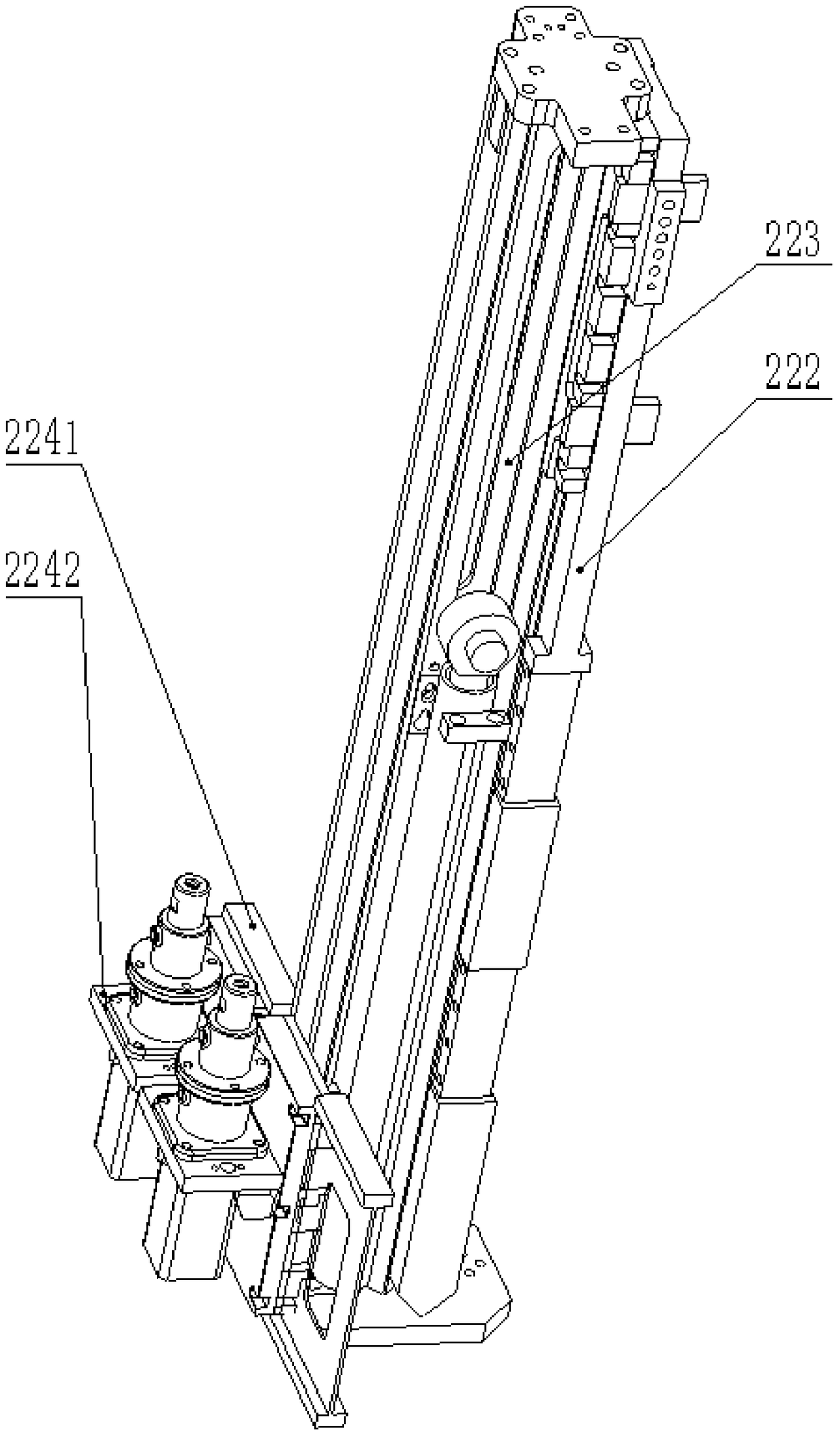

[0082] Refer to attached Figures 12 to 15 As shown, the drill arm mechanism 2' of the six-arm top bolter rig of the present invention includes a drill arm plate 21', a front slide rail group arranged on the drill arm plate 21', and a rear slide rail set arranged on the lower surface of the lifting platform 45'. Rail group 22' and six top bolt rigs (from left to right are rigs 1 to 6), the drill arm plate 21' is vertically fixed and installed on the lifting platform 45', and the six top bolt rigs are divided into two rows at the front and back Set, and the distance between the front and rear rows of drilling rigs is the distance between one row of bolts. The four top bolt rigs in the front row are lined up horizontally, and they are all installed on the front slide rail group o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com