Nitro-cotton cotton pulp dewatering method

A technology of nitrocellulose cotton and cotton pulp, applied in the field of nitrocellulose production, which can solve the problems of reduced economic benefits, high COD content in wastewater, and large product loss, so as to reduce production water consumption, reduce solid content in wastewater, and increase product yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

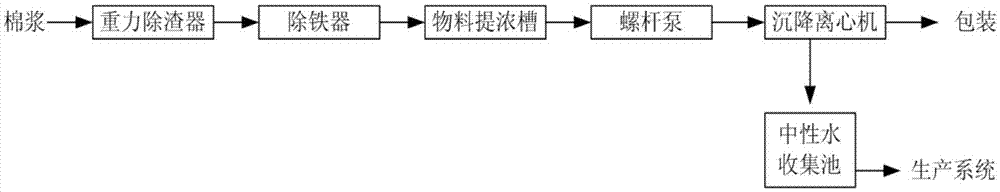

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0018] The dehydration method of nitrocellulose cotton pulp comprises the steps:

[0019] A. Remove heavy impurities and iron filings in cotton pulp;

[0020] B. Use a concentrator to adjust the concentration of the cotton pulp to increase the concentration of the cotton material in the cotton pulp to 8-15%;

[0021] C. Conveying the cotton pulp to a horizontal settling centrifuge;

[0022] D. Start the horizontal decanter centrifuge to separate the solid and liquid from the nitrocellulose pulp.

[0023] Nitrocellulose is a flammable solid. The production process, especially the dehydration process, should avoid friction, impact and static electricity. Therefore, step A should be carried out to remove heavy impurities and iron filings brought in by the cotton pulp production process and raw materials.

[0024] In order to improve production ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com