Preparation method of calcium glycinate

A technology of calcium glycine and glycine, applied in the preparation of organic compounds, chemical instruments and methods, cyanide reaction preparation, etc., can solve the problem of large amounts of by-products of acid or lye, difficulty in large-scale industrial production, and easy coking of by-products, etc. problem, achieve the effect of shortening the reaction time, increasing the yield, and increasing the reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A preparation method of calcium glycinate, comprising the following steps:

[0019] a, take by weighing 0.60g (8.0mmol) glycine and 0.44g (4.0mmol) calcium chloride anhydrous and join in the 100ml flask respectively, then add 20ml absolute ethanol;

[0020] b. The reaction system in step a above was reacted for 4 to 6 hours under the radiation of ultrasonic waves (RUC-2203DT—operating frequency: 42±1.5KHz; ultrasonic power: 100W), and a white precipitate—ultrafine powder was formed, which was left to stand;

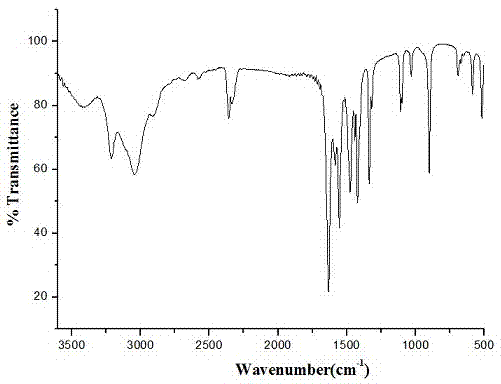

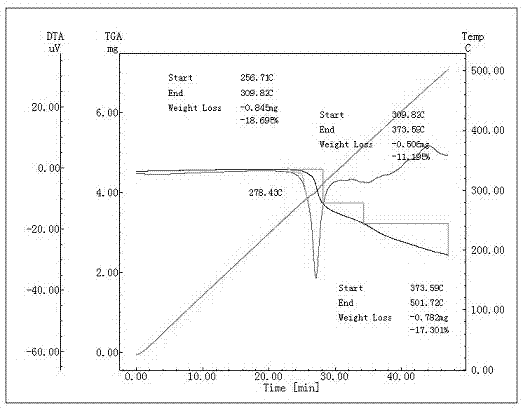

[0021] c. The reaction product in step b above was washed several times with absolute ethanol, centrifuged, and vacuum-dried at 60° C. for 24 hours to obtain 0.71 g of white ultrafine powder with a yield of 94.3%. see figure 1 , 2 , 3.

Embodiment 2

[0023] Same as Example 1, but the anhydrous calcium chloride in the b step is changed into anhydrous calcium hydroxide to obtain white ultrafine powder 0.68g, and the productive rate is 90.3%.

Embodiment 3

[0025] Same as Example 1, but the anhydrous calcium chloride in the b step is changed to anhydrous calcium oxide to obtain white ultrafine powder 0.67g, and the productive rate is 89.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com