Preparation method of carbon nanotube film

A technology of carbon nanotube film and carbon nanotube, which is applied in the direction of carbon nanotube, nanocarbon, nanotechnology, etc., can solve the problems of limited length of carbon nanotube yarn and application limitation of carbon nanotube yarn, and achieve the goal of improving mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

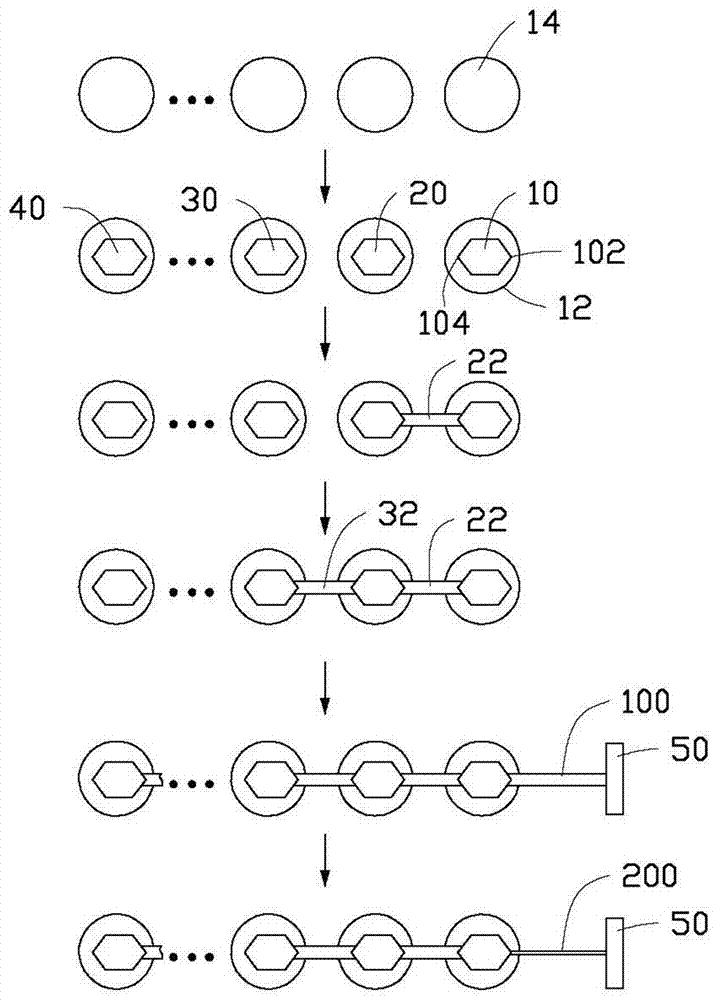

[0027] Please also see Figure 1 to Figure 3 , the first embodiment of the present invention provides a method for preparing a carbon nanotube film 100, comprising the following steps:

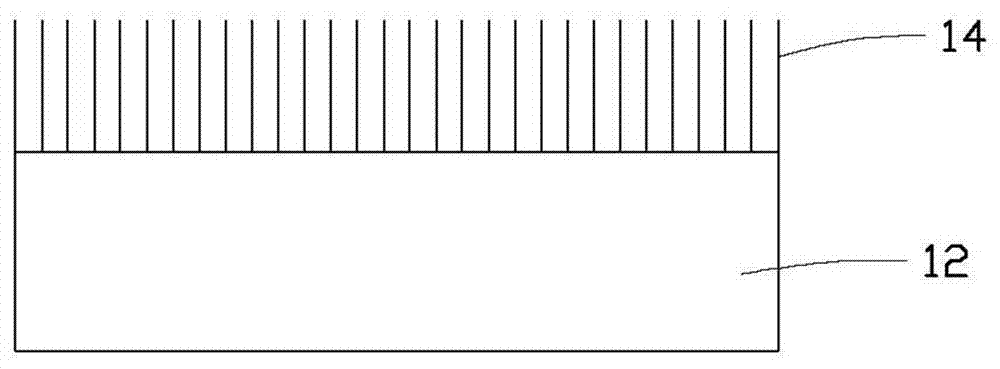

[0028] S10, providing a plurality of carbon nanotube arrays 14, the plurality of carbon nanotube arrays 14 are arranged at intervals along a horizontal direction, and the horizontal direction is defined as an X direction;

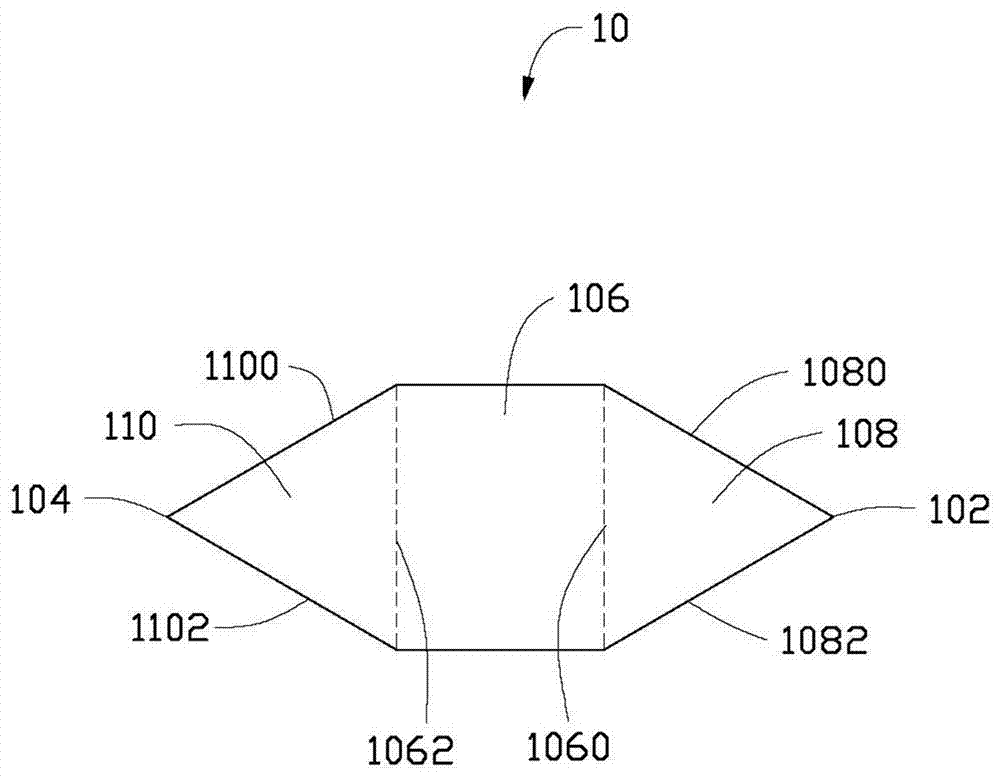

[0029] S20, patterning the plurality of carbon nanotube arrays 14 to form a plurality of patterned carbon nanotube arrays, and naming them successively as the first patterned carbon nanotube array 10 and the second patterned carbon nanotube array 20. Up to the Nth patterned carbon nanotube array 40, each patterned carbon nanotube array has opposite first end points 102 and second end points 104, and the first end point 102 of each patterned carbon nanotube array is connected to The second end points 104 of adjacent patterned carbon nanotube arrays are adjacent, and the N i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com