Non-supported catalyst and preparation method and application thereof

A catalyst and carrier-free technology, which is applied in the preparation of heterocyclic compounds, chemical instruments and methods, and the preparation of hydroxyl compounds, etc., can solve the problems of limiting the effect of additives, achieve the effects of improving catalytic reaction performance, low product cost, and promoting reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] A preparation method for an iron-based inversion catalyst that can be used for Fischer-Tropsch synthesis, comprising the steps of:

[0072] 1. Preparation of active metal oxide nanoparticles:

[0073] Weigh 1.95g of ferric chloride and 0.2g of trisodium citrate, add 40ml of ethylene glycol after mixing, and stir for 0.5h to obtain solution A;

[0074] Weigh 4g of sodium acetate and dissolve it in 40ml of glycerol, stir for 0.5h to obtain solution B;

[0075] Slowly add solution B to solution A, and keep stirring for 3h;

[0076] Move the above solution into a polytetrafluoroethylene container, seal it in a stainless steel autoclave, heat and react at 150°C for 10 hours, and then cool it to room temperature; after centrifuging the above product, wash it with ethanol three times, and then heat it at 60°C Drying for 10 h under the hood to obtain ferric oxide microspheres with a diameter of about 250 nm.

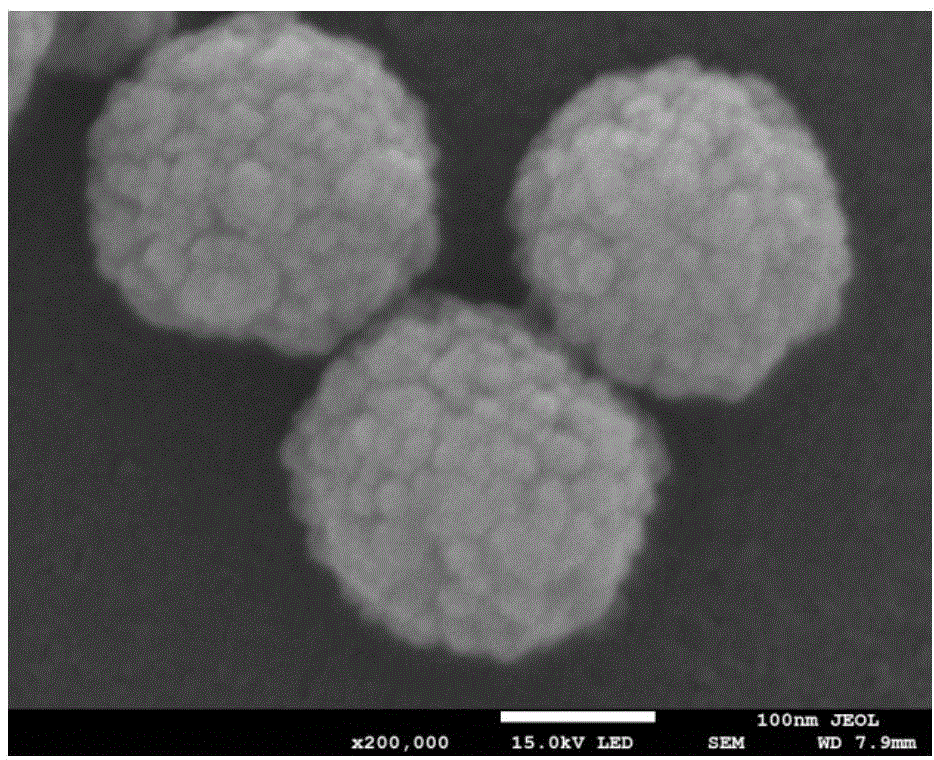

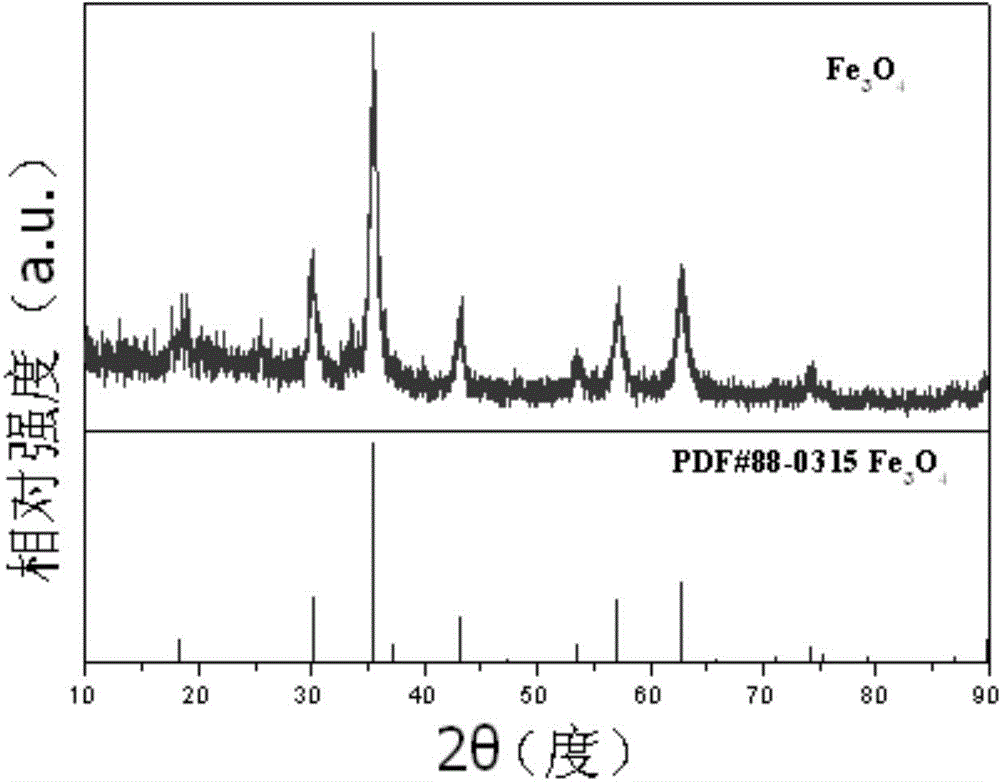

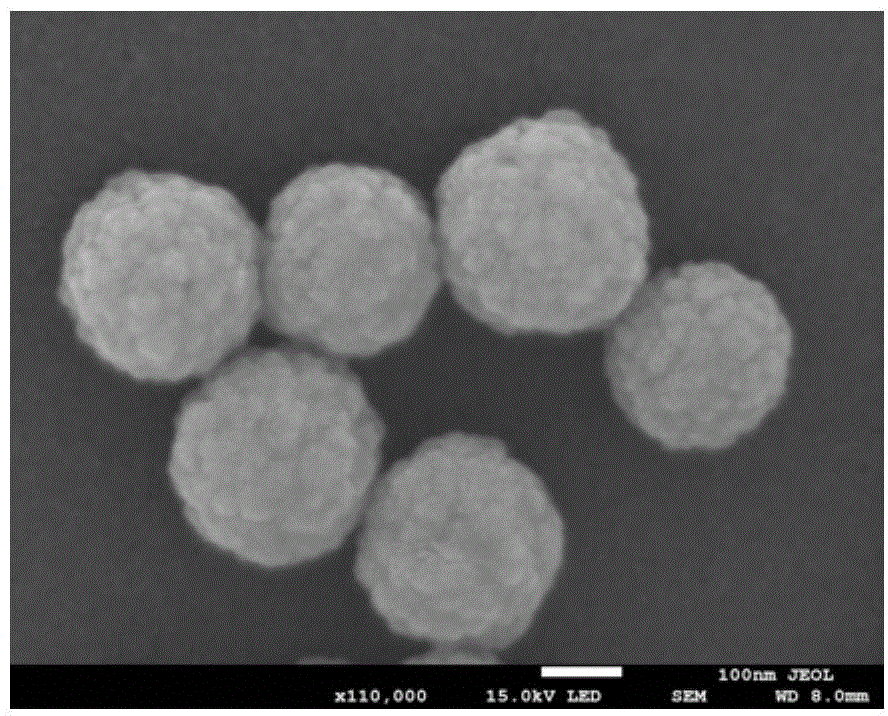

[0077] figure 1 It is the SEM image of the ferric oxide microsph...

Embodiment 2

[0089] Same as Example 1, the difference is:

[0090] 2. In the preparation of the catalyst:

[0091] 1) The drying temperature is 60°C, and the temperature is constant for 12 hours;

[0092] 2) The drying temperature is 60°C, and the temperature is constant for 24 hours.

[0093] The catalyst obtained is identical to the application of Example 1, and the reaction results are shown in Table 1.

Embodiment 3

[0095] Same as Example 1, the difference is:

[0096] 2. In the preparation of the catalyst:

[0097] 1) The drying temperature is 180°C, and the temperature is constant for 24 hours;

[0098] 2) The drying temperature is 180°C, and the temperature is kept constant for 48 hours.

[0099] The application method of the obtained catalyst is the same as in Example 1, and the reaction results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com