Water heavy metal ion attapulgite adsorbent

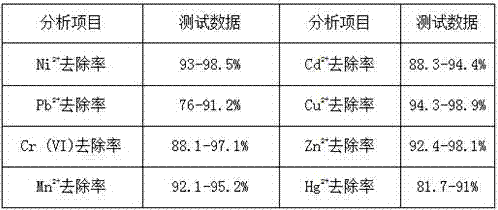

A technology of heavy metal ions and attapulgite, which is applied in the direction of adsorbing water/sewage treatment, water pollutants, water/sewage treatment, etc., to achieve the effects of reducing preparation cost, improving adsorption performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A water heavy metal ion attapulgite adsorbent, comprising the steps of:

[0039] A. Acidification

[0040] Using attapulgite clay as raw material, attapulgite clay, water and sulfuric acid are prepared in parts by weight, 45 parts of attapulgite clay, 35 parts of water, 0.5 part of sulfuric acid with a mass fraction of 98%, and the sulfuric acid with a mass fraction of 98% is diluted in water , diluted with sulfuric acid and sprayed on the attapulgite clay, stirred evenly and stacked for 24 hours;

[0041] B. smash

[0042] Pulverizing the acidified attapulgite clay;

[0043] C. Sieving

[0044] The crushed attapulgite clay is sieved and divided into four specifications of less than 0.1mm, 0.1-0.3mm, 0.3-0.5mm and 0.5-1mm according to the particle size;

[0045] D. Roasting

[0046] Attapulgite clay of four specifications was roasted separately, and after roasting at 450°C for 1 hour, the balls were dehydrated and solidified, then cooled naturally to room temperatu...

Embodiment 2

[0048] A water heavy metal ion attapulgite adsorbent, comprising the steps of:

[0049] A. Acidification

[0050] Using attapulgite clay as raw material, attapulgite clay, water and hydrochloric acid are prepared in parts by weight, 60 parts of attapulgite clay, 40 parts of water, 1 part of hydrochloric acid with a mass fraction of 37%, and the hydrochloric acid with a mass fraction of 37% is diluted in water , diluted with sulfuric acid and sprayed on the attapulgite clay, stirred evenly and stacked for 60 hours;

[0051] B. smash

[0052] Pulverizing the acidified attapulgite clay;

[0053] C. Sieving

[0054] The crushed attapulgite clay is sieved and divided into four specifications of less than 0.1mm, 0.1-0.3mm, 0.3-0.5mm and 0.5-1mm according to the particle size;

[0055] D. Roasting

[0056] Attapulgite clay of four specifications was roasted separately, and after roasting at 550°C for 2 hours, the balls were dehydrated and solidified, then cooled naturally to roo...

Embodiment 3

[0058] A water heavy metal ion attapulgite adsorbent, comprising the steps of:

[0059] A. Acidification

[0060] Using attapulgite clay as raw material, attapulgite clay, water and phosphoric acid are prepared in parts by weight, 65 parts of attapulgite clay, 50 parts of water, 2 parts of phosphoric acid with a mass fraction of 98%, and the phosphoric acid with a mass fraction of 98% is diluted in water , diluted with sulfuric acid and sprayed on the attapulgite clay, stirred evenly and stacked for 72 hours;

[0061] B. smash

[0062] Pulverizing the acidified attapulgite clay;

[0063] C. Sieving

[0064] The crushed attapulgite clay is sieved and divided into four specifications of less than 0.1mm, 0.1-0.3mm, 0.3-0.5mm and 0.5-1mm according to the particle size;

[0065] D. Roasting

[0066] Attapulgite clay of four specifications was roasted separately, and after roasting at 550°C for 2 hours, the balls were dehydrated and solidified, then cooled naturally to room tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com