Overlaying buckling sheet tooling

A tooling and buckle technology, which is applied in electromechanical devices, manufacturing motor generators, manufacturing stator/rotor bodies, etc., can solve problems such as low bending quality, low production efficiency, damage to buckle or stator punching, and achieve folding The effect of high bending quality, high alignment accuracy and fast bending speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

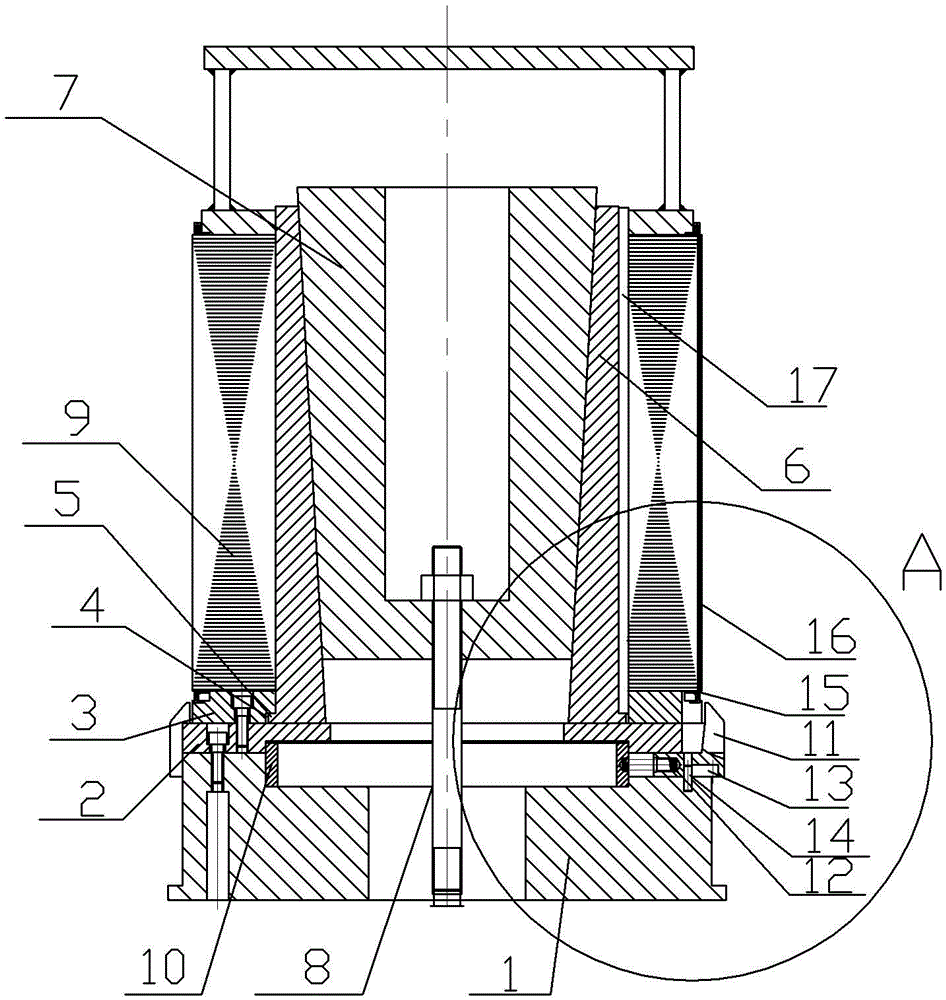

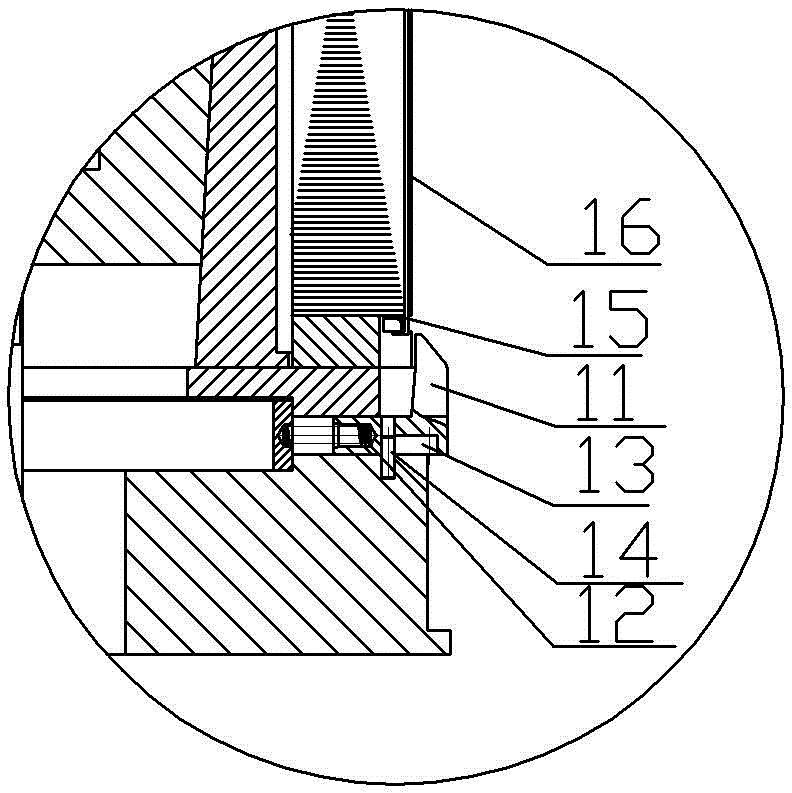

[0020] A stack of buckle tooling is basically attached figure 1 , figure 2 As shown: it includes a base 1 fixed on the sheet lamination machine by bolts. There is a shaft hole in the center of the base 1. The shaft hole is a stepped hole, and an inner retaining ring 10 is interference fit at the step of the stepped hole. The upper end surface of the base 1 is fixed with an annular backing plate 2 by hexagon socket head cap screws. A cylindrical core 6 is placed on the backing plate 2, and the core 6 is assembled from three independent core valves. There is a tapered hole in the core tire 6, and the diameter of the tapered hole decreases gradually from top to bottom. The tapered hole, the backing plate 2, and the stepped hole of the base 1 are concentric.

[0021] The surface of the backing plate 2 is fixed with a ring-shaped lower pressure ring 3 by hexagon socket head screws. The lower pressure ring 3 is located on the periphery of the core tire 6 and is concentric with th...

Embodiment 2

[0025] The difference from Embodiment 1 is that a linear drive motor is used to replace the telescopic cylinder, and the output shaft of the linear drive motor is connected to the lower end of the screw rod 8 through a flange.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com