Method for evaluating corrosion resistance of welded joint based on potential testing technology

A technology for welding joints and corrosion performance, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of long test period, cumbersome sample preparation, large test error, etc., to achieve short test period and economic cost. Low, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for evaluating the corrosion performance of welded joints based on potential testing technology provided in this embodiment includes the following steps:

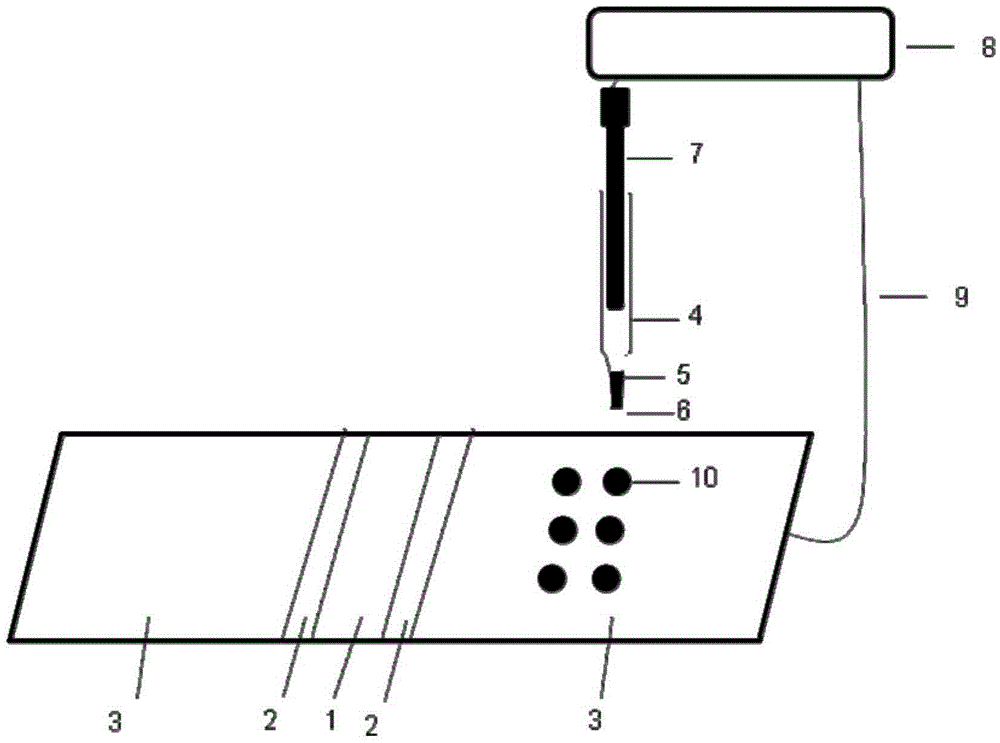

[0021] (1) Preparation of samples: After mechanical processing, the welded joint samples are ground and polished on a metallographic grinding and polishing machine, and the welded joints are corroded with a metallographic corrosive solution. The degree of corrosion can distinguish the weld zone 1 and the fusion zone , heat-affected zone 2 and base metal 3 are suitable;

[0022] (2) Preparation of corrosion solution: According to the main influencing factors of the welded joint service environment, prepare a suitable welded joint corrosion solution 10, so that the corrosion mechanism of the welded joint under the corrosion solution 10 is consistent with the corrosion mechanism of the welded joint under the service environment , the corrosion rate of the welded joint in the corrosive solution 10 may be differe...

Embodiment 2

[0030] A method for evaluating the corrosion performance of welded joints based on potential testing technology provided in this embodiment includes the following steps:

[0031] (1) Preparation of samples: After mechanical processing, the welded joint samples are ground and polished on a metallographic grinding and polishing machine, and the welded joints are corroded with a metallographic corrosive solution. The degree of corrosion can distinguish the weld zone 1 and the fusion zone , heat-affected zone 2 and base metal 3 are suitable;

[0032] (2) Preparation of corrosion solution: According to the main influencing factors of the welded joint service environment, prepare a suitable welded joint corrosion solution 10, so that the corrosion mechanism of the welded joint under the corrosion solution 10 is consistent with the corrosion mechanism of the welded joint under the service environment , the corrosion rate of the welded joint in the corrosive solution 10 may be differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com