Laser marking galvanometer scanning system based on machine vision

A laser marking and machine vision technology, applied in the field of laser marking galvanometer scanning system, can solve the problems of difficult to improve the overall efficiency, difficult to achieve automation, and restrict the development and application of laser marking technology, and achieve a high degree of automation and convenience. Recognition, stabilization and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

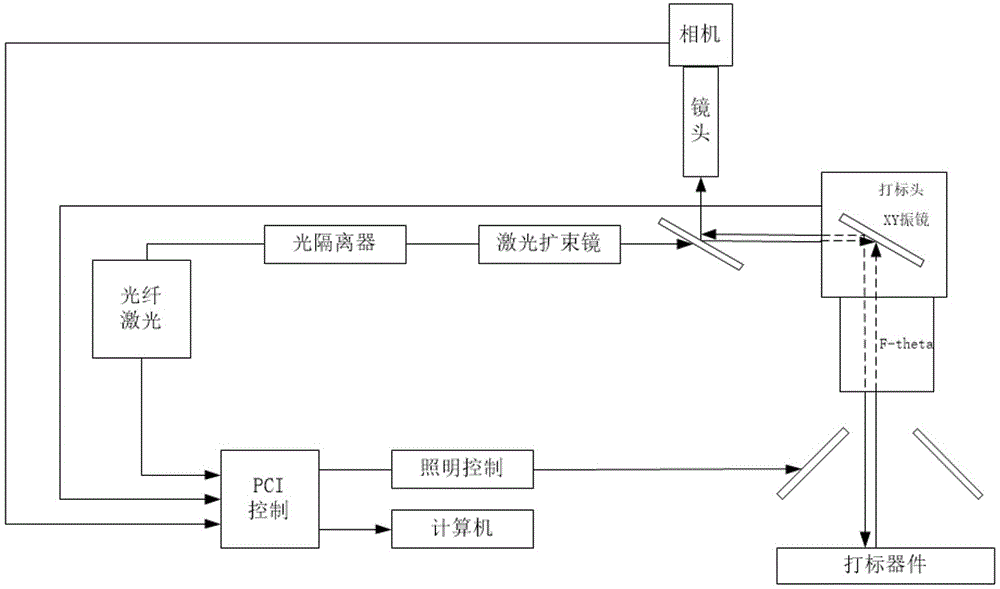

[0031] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a machine vision laser marking galvanometer scanning system proposed by the present invention.

[0032] refer to figure 1 , a machine vision laser marking galvanometer scanning system proposed by the present invention includes an image processing system, a laser galvanometer scanning system, and a motion control system, specifically including a light source, a lens, a CCD camera, an image acquisition card, image processing software, Fiber lasers, optical isolators, laser beam expanders, XY scanning galvanometers, F-theta lenses, monitors, communication / input / output units, three-dimensional adjustment brackets, etc. In the present invention, the marking device group is illuminated by an 890nm LED lighting lamp, and its reflected light enters the CCD camera for imaging after passing through the F-theta lens, XY galvanometer, 45-degree mirror, and camera lens, and the camera transmits the digital...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com