A method for measuring the rotation angle of a rotating shaft to suppress the rotation error of the shafting inclination angle

A technology of inclination rotation and measurement method, which is applied in the measurement of the rotation angle of the rotating shaft and the field of high-precision rotation angle measurement of the rotating shaft, which can solve the problems affecting the accuracy of the rotation angle measurement of the rotating shaft 2, the rotation error, the processing error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

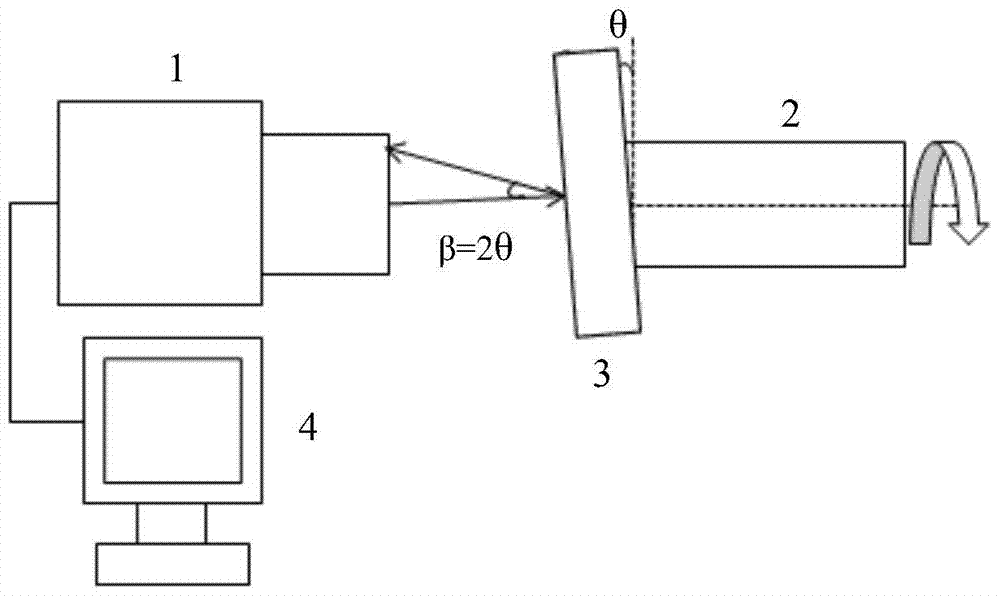

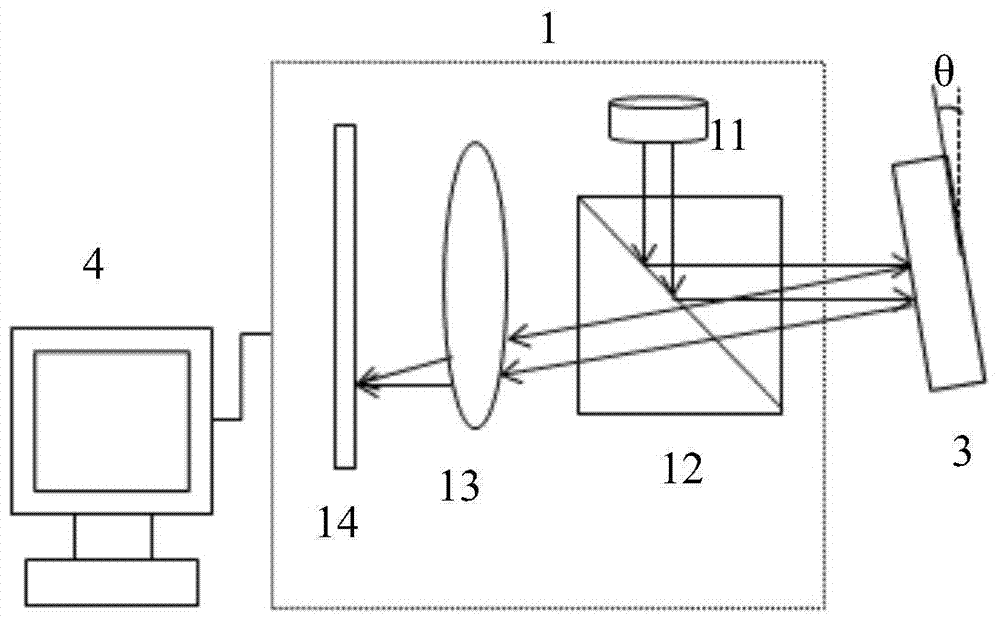

[0028] 1) Autocollimator 1 is Collapex AC300, a product of Xi'an Angke Spot Technology Co., Ltd., with an effective aperture of 32mm, a focal length of 300mm, and an imaging field of view of 50 arc minutes;

[0029] 2) The rotating shaft 2 is a hollow rotating shaft fixed with the worm wheel in the worm gear mechanism, driven by a servo motor, and the servo motor is connected with the computer 4;

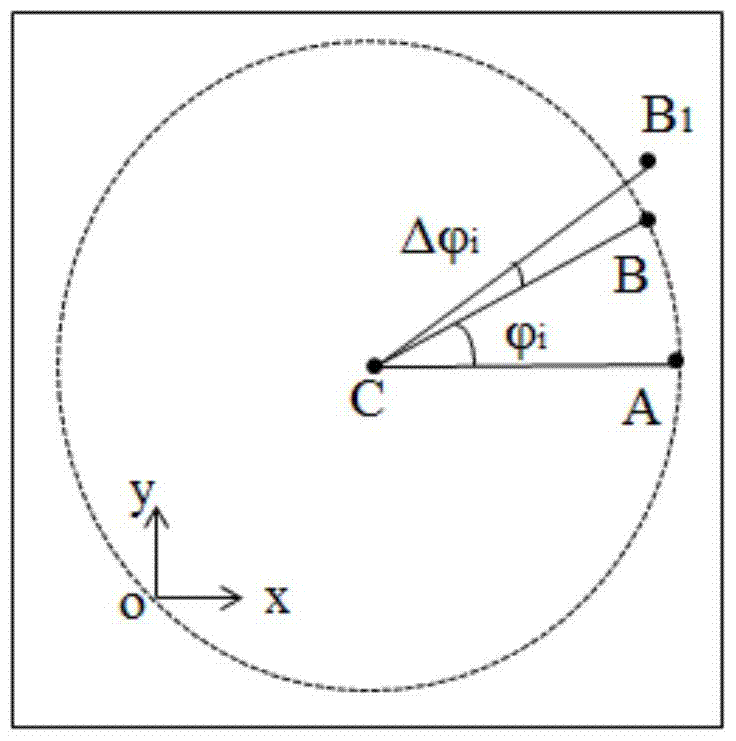

[0030] 3) the computer 4 that links to each other with autocollimator 1 is the incidental equipment of autocollimator 1, and the program 1 that producer is given is installed on it, and the function of program 1 is: provide main interface on the display screen of computer 4, The position of the spot image is displayed on the main interface as a reticle, the center of the reticle is located at the centroid of the spot image, and the reticle moves synchronously with the position of the spot image; establish a Cartesian coordinate system and move along the display The horizontal direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com