Acting part of water-based fire extinguishing bomb

A fire-extinguishing bomb and warhead technology, which is applied to the warhead field of water-based fire-extinguishing bombs, can solve the problems of no safety isolation measures for fire transmission, single detonation mode of fire-extinguishing bombs, and high explosive throwing power, etc., so as to shorten the detonation time and fragment scattering The effect of small distance and low explosion power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in detail below.

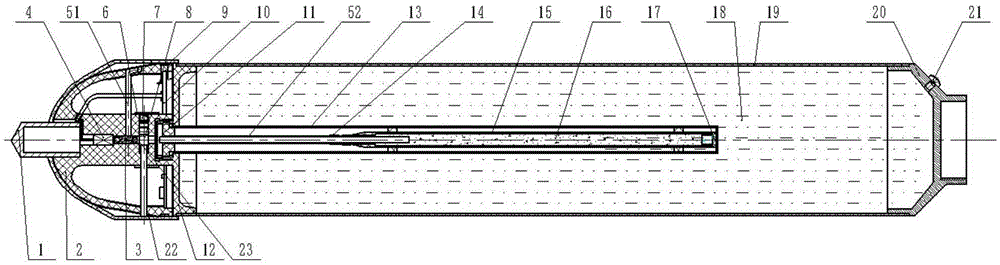

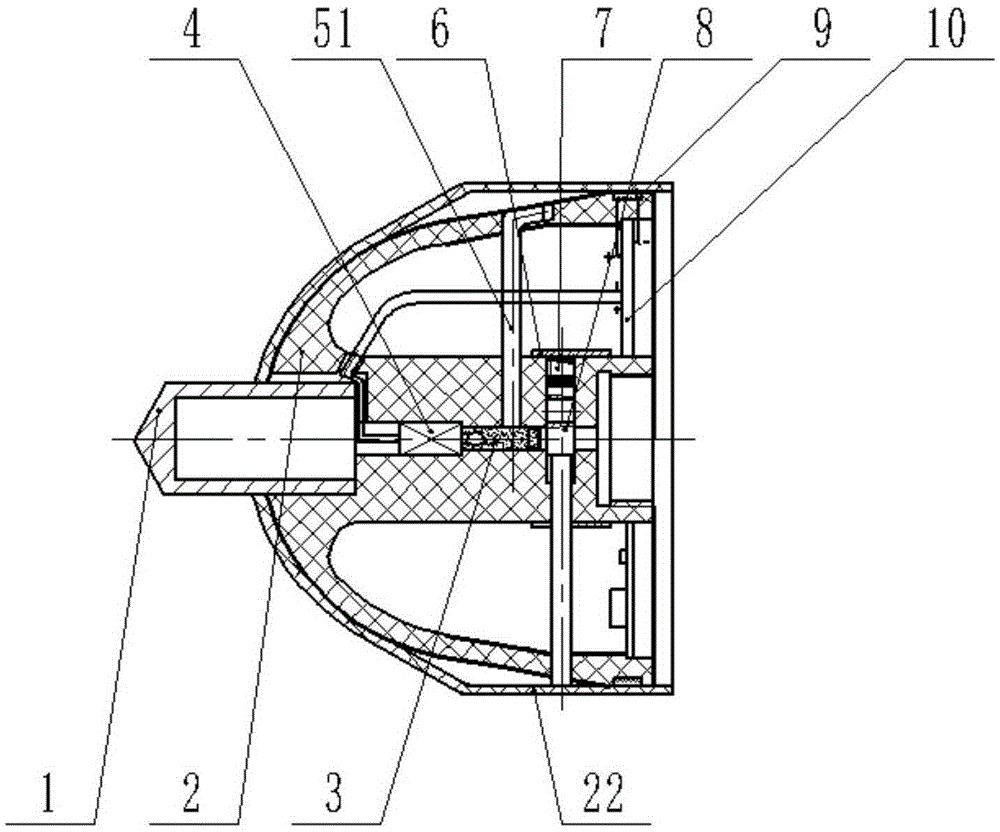

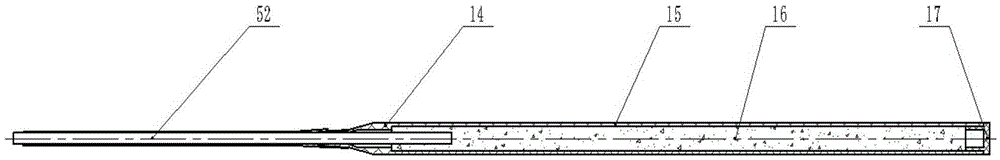

[0025] Such as Figure 1 to Figure 5 As shown, the invention discloses a warhead of a water-based fire extinguishing bomb, which includes a detonating device and a bomb body device fixed at the rear end of the detonating device.

[0026] The detonating device comprises an impact head 1 and a head screw 2, one end of the impact head 1 is embedded in the head screw 2, and the other end is located outside the head screw 2. When extinguishing a building, the impact head 1 is used to break the glass on the building and enter the room; the head screw 2 is provided with a medicine bowl 3, an electric ignition head 4, an external ignition wire 51, an induction secondary coil 9, and an ignition control print. Plate making 10 and isolation mechanism; the induction secondary coil 9 is placed in the annular groove in the head screw 2, the induction secondary coil 9 is connected with the ignition control prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com