Preparation method of non-woven interior decoration material containing silver-loaded titanium dioxide for vehicles

A technology of silver-loaded titanium dioxide and nano-titanium dioxide, which is applied in the processing of textile materials, continuous processing of textile materials, textiles and papermaking, etc., can solve the problems of difficult to ensure the effect of spraying process and durable scrubbing, difficult to guarantee the quality of the solution, and uncomfortable operation and other problems, to achieve the effect of stable release rate, long-term effect, wide antibacterial range and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

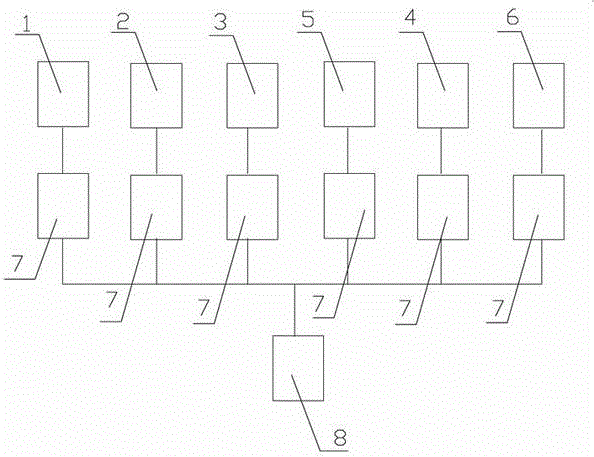

[0027] A method for preparing a non-woven interior decoration material containing silver-loaded titanium dioxide for vehicles, which is characterized by comprising: a mixed solution preparation system 1, a dipping system 2, a heating system 3, an air cooling system 4, a setting system 5, a cutting system 6, The emergency shutdown system 7 and the comprehensive control system 8, the mixed solution preparation system 1, the dipping system 2, the heating system 3, the air cooling system 4, the setting system 5 and the cutting system 6 are connected by signals, and the mixed solution preparation system 1 , impregnation system 2, heat drying system 3, air cooling system 4, sizing system 5 and cutting system 6 are respectively connected to emergency stop system 7, the mixed liquid preparation system 1, impregnation system 2, heat drying system (3) , air cooling system 4, sizing system 5 and the emergency stop system 7 connected on the cutting system 6 are all connected with the integ...

Embodiment 2

[0037] A method for preparing a non-woven interior decoration material containing silver-loaded titanium dioxide for vehicles, which is characterized by comprising: a mixed solution preparation system 1, a dipping system 2, a heating system 3, an air cooling system 4, a setting system 5, a cutting system 6, The emergency shutdown system 7 and the comprehensive control system 8, the mixed solution preparation system 1, the dipping system 2, the heating system 3, the air cooling system 4, the setting system 5 and the cutting system 6 are connected by signals, and the mixed solution preparation system 1 , impregnation system 2, heat drying system 3, air cooling system 4, sizing system 5 and cutting system 6 are respectively connected to emergency stop system 7, the mixed liquid preparation system 1, impregnation system 2, heat drying system (3) , air cooling system 4, sizing system 5 and the emergency stop system 7 connected on the cutting system 6 are all connected with the integ...

Embodiment 3

[0049] A method for preparing a non-woven interior decoration material containing silver-loaded titanium dioxide for vehicles, which is characterized by comprising: a mixed solution preparation system 1, a dipping system 2, a heating system 3, an air cooling system 4, a setting system 5, a cutting system 6, The emergency shutdown system 7 and the comprehensive control system 8, the mixed solution preparation system 1, the dipping system 2, the heating system 3, the air cooling system 4, the setting system 5 and the cutting system 6 are connected by signals, and the mixed solution preparation system 1 , impregnation system 2, heat drying system 3, air cooling system 4, sizing system 5 and cutting system 6 are respectively connected to emergency stop system 7, the mixed liquid preparation system 1, impregnation system 2, heat drying system (3) , air cooling system 4, sizing system 5 and the emergency stop system 7 connected on the cutting system 6 are all connected with the integ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com