A fe-b-si-based bulk amorphous alloy with high saturation magnetization

A magnetization, amorphous alloy technology, applied in the direction of magnetic objects, magnetic materials, electrical components, etc., can solve the problems of unfavorable amorphous alloy saturation magnetization, reduction of Fe content in alloys, etc., to achieve high saturation magnetization, high amorphous alloy. Effect of crystal forming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the following, the present invention will be specifically introduced from two aspects of alloy preparation and alloy properties.

[0020] 1. Preparation of amorphous alloy

[0021] The preparation scheme of the Fe-B-Si series bulk amorphous alloy adopted in the present invention comprises:

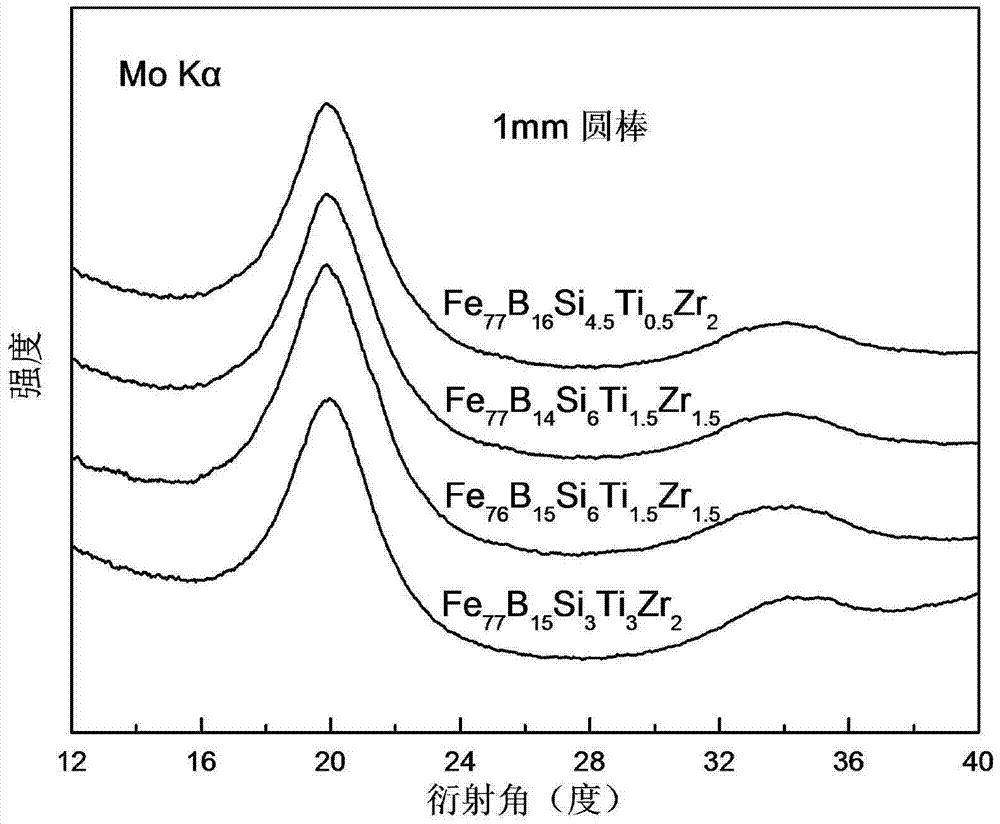

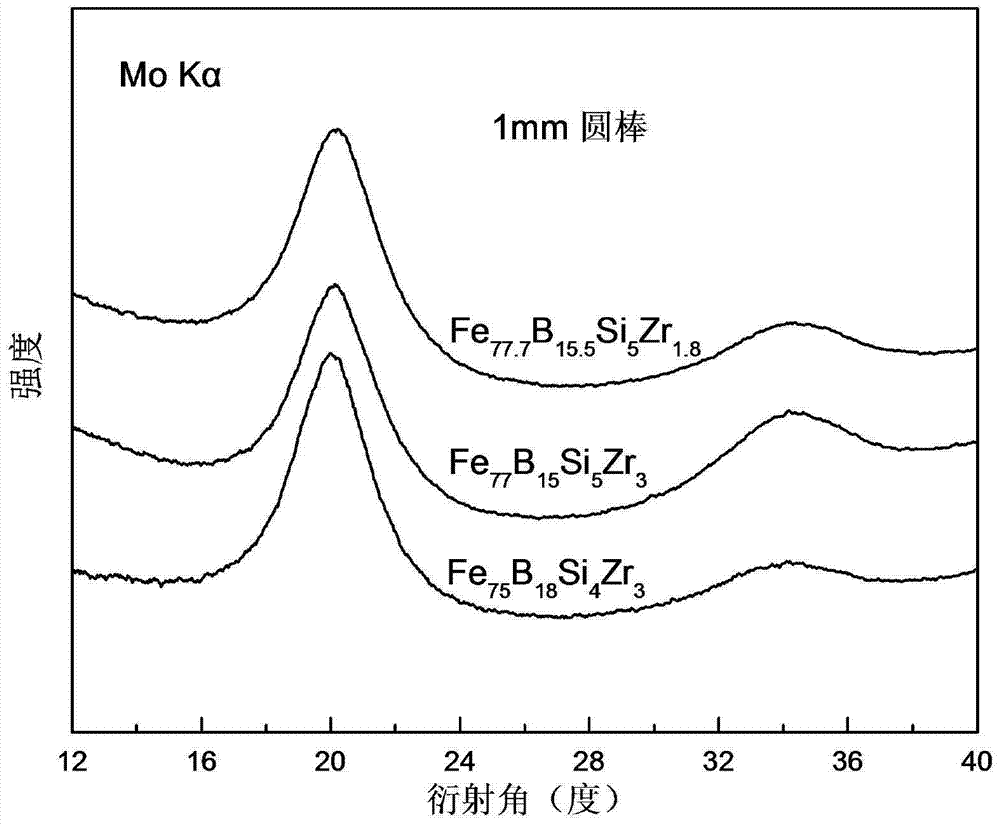

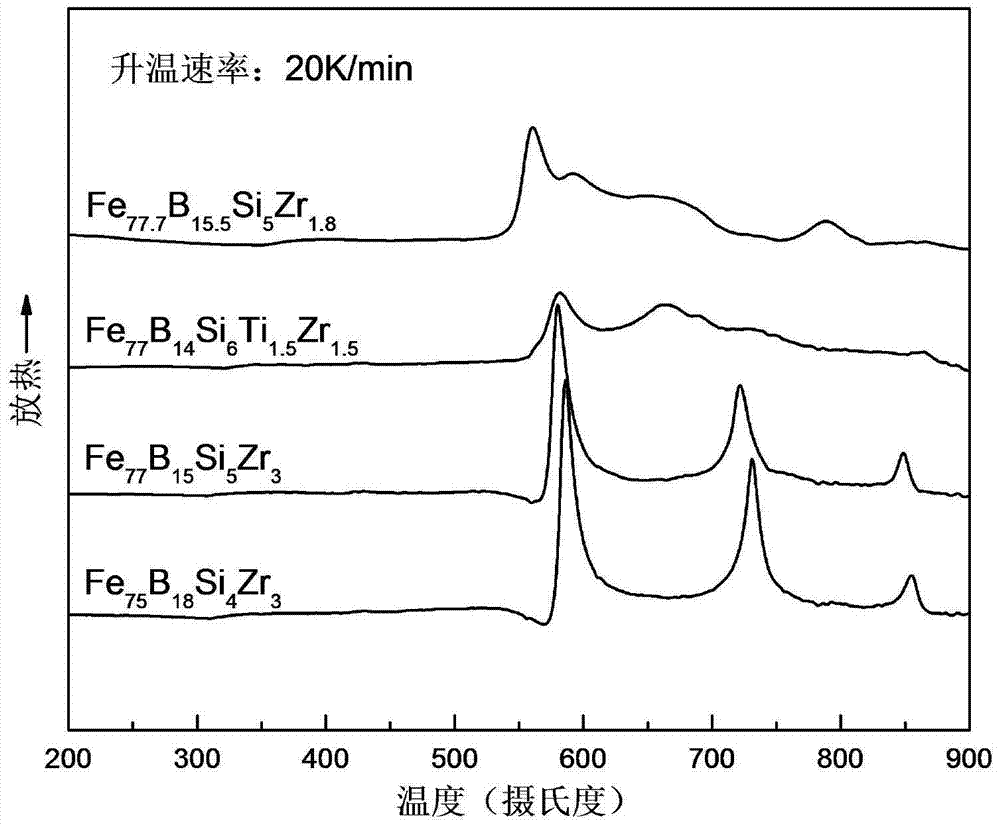

[0022] (1) According to the chemical composition Fe a B b Si c Ti d Zr e Precise allocation of alloy raw materials. The composition characteristics are: 75≤a≤79, 12≤b≤19, 2≤c≤9, 0≤d≤5, 1≤e≤3.5, 1≤d+e≤6, a+b+c+d+ e=100.

[0023] (2) The purity of the raw materials Fe, Zr or Ti used is not less than 99.8%, the purity of Si is not less than 99.5%, and B is added in the form of industrial boron Fe alloy (impurity content is less than 0.7%);

[0024] (3) Grinding and removing the surface oxide skin of the metal raw material, carrying out accurate weighing and proportioning according to the molar ratio and using ethanol to ultrasonically clean the raw material;

[0025] (4) Us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical dimension | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| critical dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com