Anti-corrosion waterproof material and preparing and using method thereof

A waterproof material and mixed technology, applied in anti-corrosion coatings, building insulation materials, building components and other directions, can solve the problems of difficult to remove blisters, weak impact resistance, poor material hardness, etc., to solve the problem of waterproof leakage, Strong adhesion and flexible construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 of the present invention provides an anti-corrosion and waterproof material, which is prepared by mixing the following components in parts by weight: 50-70 parts of composite unsaturated resin, 5-10 parts of organic solvent, 3-6 parts of curing agent, 2 to 4 parts of catalyst, 25 to 40 parts of powder with anti-caking properties; wherein, the composite unsaturated resin is a composite unsaturated resin prepared by adding nano-scale carbon fibers into the unsaturated resin, and the unsaturated resin is mixed with The weight ratio of the nano-scale carbon fiber is (6-15): (1-5), the nano-scale carbon fiber is used to increase the strength of the composite unsaturated resin after curing; The nano-scale powder with anti-caking properties obtained after grinding treatment. In actual application, the material is prepared by mixing the following raw materials in parts by weight: 55-65 parts of composite unsaturated resin, 7-9 parts of organic solvent, 4-5 parts of...

Embodiment 2

[0031] Embodiment 2 of the present invention provides a method for preparing an anti-corrosion and waterproof material, the method comprising:

[0032] Take the unsaturated resin with a weight fraction of 6-15 parts and the carbon fiber with a weight fraction of 1-5 parts, grind the carbon fiber to obtain the ground nano-scale carbon fiber, add the obtained nano-scale carbon fiber to the unsaturated resin internally and stir evenly to obtain a composite unsaturated resin; in practical application, when preparing the composite unsaturated resin, the carbon fiber with a weight fraction of 6 parts of unsaturated resin and 1 part of carbon fiber can be taken, and the carbon fiber is ground. , to obtain the nano-scale carbon fiber after grinding, add the obtained nano-scale carbon fiber into the unsaturated resin and stir evenly to obtain a composite unsaturated resin; further, the weight fraction can be 8 parts of unsaturated resin and 4 parts of unsaturated resin Carbon fiber, gr...

Embodiment 3

[0034] Embodiment 3 of the present invention provides a method for using an anti-corrosion and waterproof material, the method comprising:

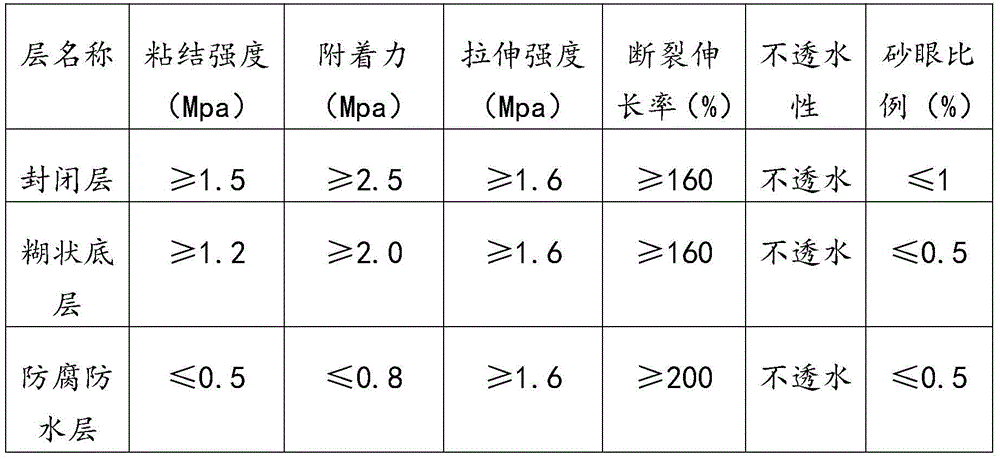

[0035] The first primer: Take 50-70 parts of composite unsaturated resin, 5-10 parts of organic solvent, 3-6 parts of curing agent, and 2-4 parts of catalyst to make a primer, and mix the primer evenly Lay it on the surface of the part to be treated for anti-corrosion and waterproofing to form a sealing layer; in practical application, you can take 50 parts of composite unsaturated resin, 5 parts of organic solvent, 3 parts of curing agent, and 2 parts of catalyst to make a primer. Also can take 60 parts of composite unsaturated resin, 8 parts of organic solvent, 4 parts of curing agent, 3 parts of catalyst and mix uniformly to prepare the primer. Also can take 70 parts of composite unsaturated resin, 10 parts of organic solvent, 6 parts of curing agent, 4 parts of catalyst and mix uniformly to prepare the primer.

[0036] The second pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com