High-solid-content aliphatic acrylic polyurethane paint and preparation method thereof

A technology of acrylic polyurethane and high solid content, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of low construction solid content, poor mechanical properties, and easy sagging during construction, and achieve high construction solid content and excellent construction performance Good, low VOC emission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

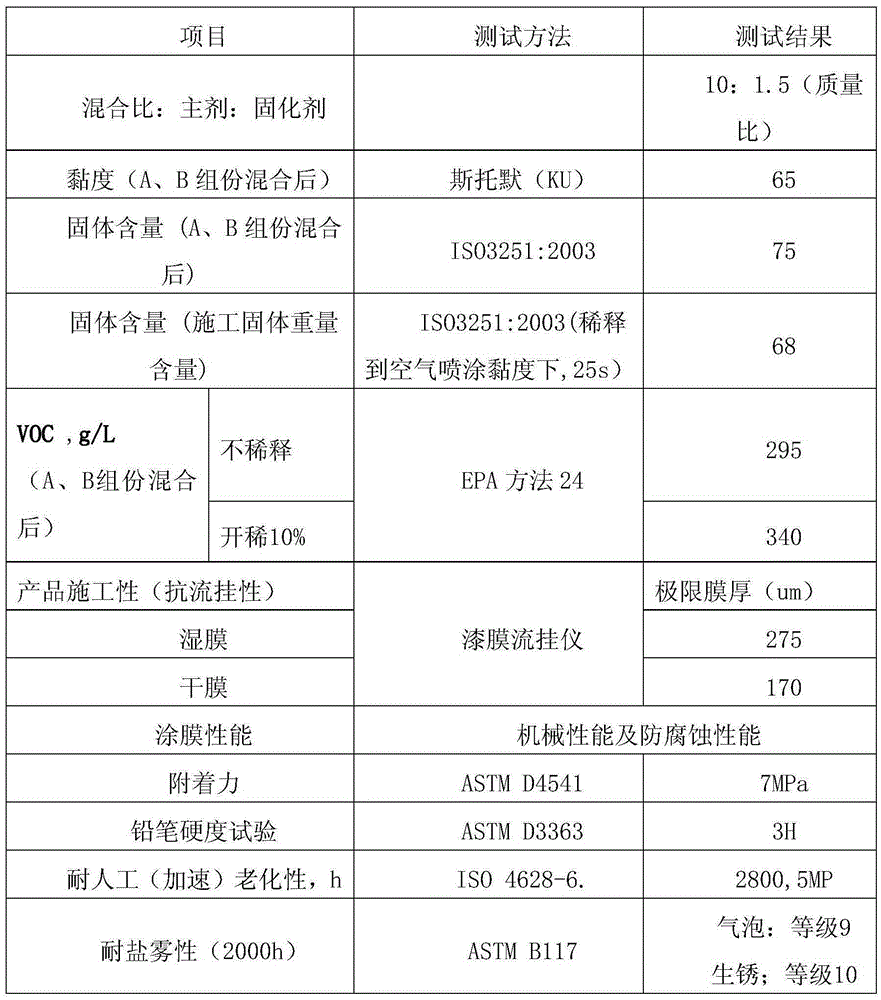

Embodiment 1

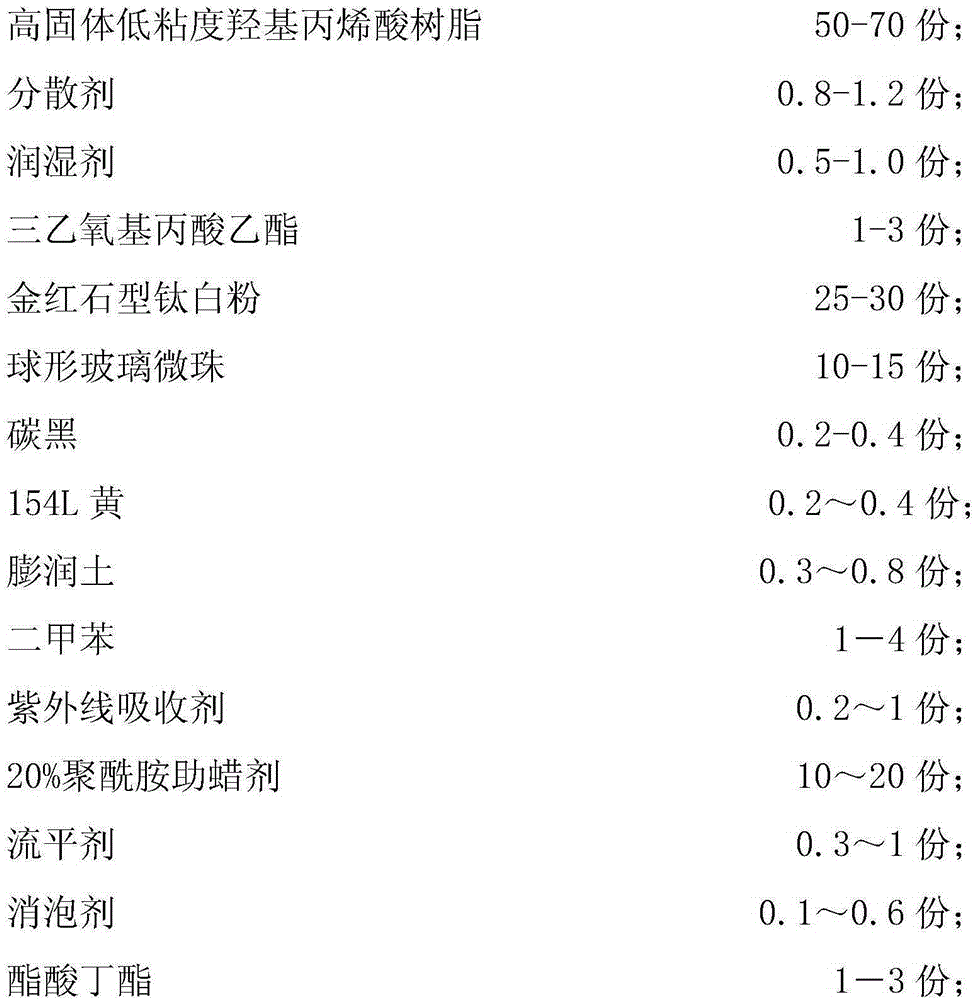

[0043] Component A:

[0044] 1) Preparation of 20% polyamide wax additives: 20 parts by weight of PA3X-20 polyamide wax from French Clayville Company and 50 parts by weight of French Akema Company After mixing 854BA80 high-solid and low-viscosity hydroxyl acrylic resin, disperse at 1500r / min until it becomes a transparent pre-gel, and the fineness is below 20um. Add 30 parts of butyl acetate under low-speed dispersion, stir evenly, and set aside.

[0045] 2) Proportioning by weight, 70 parts 854BA80 high-solid and low-viscosity hydroxyl acrylic resin is metered into the tank, and 0.8 parts of BYK110 from BYK Chemical Company, 0.5 parts of BYKP104S from BYK Chemical Company, 1 part of ethyl triethoxy propionate, 25 parts are added at a speed of 500 r / min. 1 part of rutile titanium dioxide, 10 parts of spherical glass microspheres, 0.2 part of carbon black, 0.2 part of 154L yellow, 0.5 part of bentonite, 2 parts of xylene. In the next grinding process, pass through the grinde...

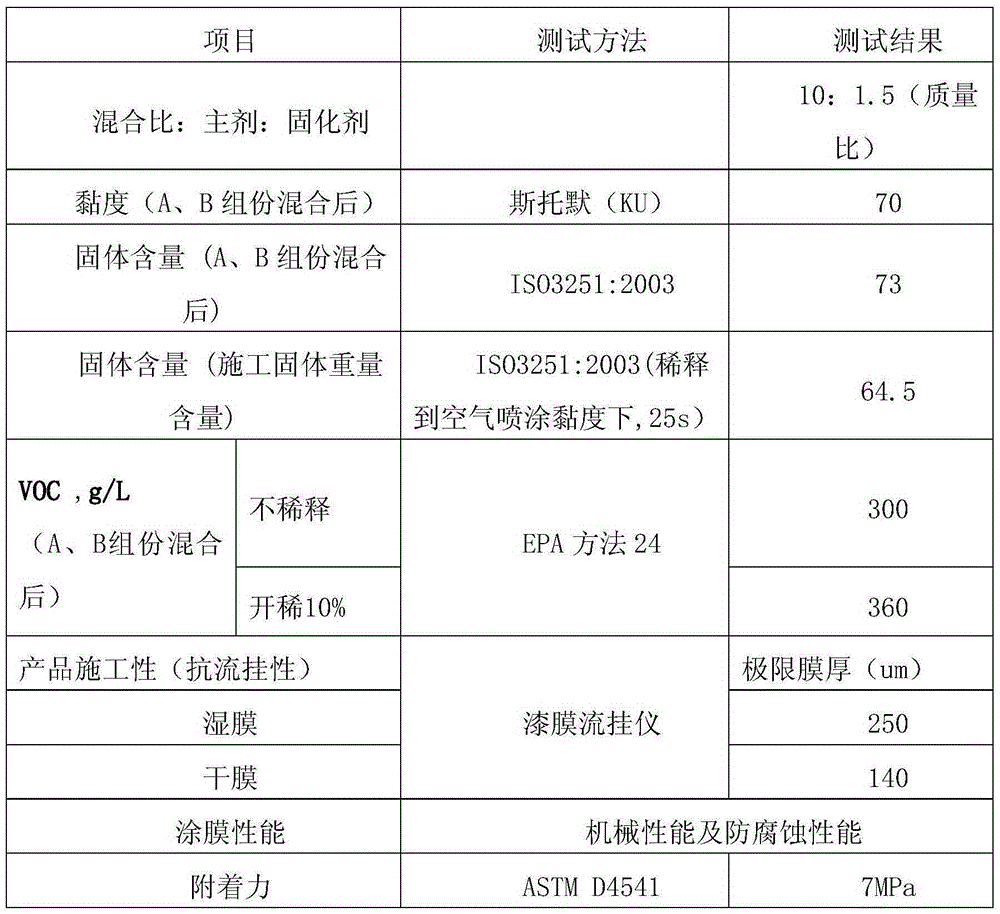

Embodiment 2

[0063] Component A:

[0064] 1) Preparation of 20% polyamide wax additive: 20 parts by weight of JSP-1068 polyamide wax from Japan Phoebe Company and 50 parts by weight of 73006D (80%) high-solid and low-viscosity hydroxyl acrylic resin from Taiwan Changxing Chemical Co., Ltd. After mixing, disperse at 1500r / min until it becomes a transparent pre-gel, and the fineness is detected to be below 20um. Add 30 parts of butyl acetate at a low speed, stir evenly, and set aside.

[0065] 2) According to the proportion by weight, 50 parts of 73006D (80%) high-solid and low-viscosity hydroxyl acrylic resin are metered into the tank, and 1.2 parts of Disponer9250 of Hemings Co., Ltd. of the United States and 0.5 part of BASF Corporation are added at a speed of 500r / min. EFKA5065, 2 parts of ethyl triethoxy propionate, 28 parts of rutile titanium dioxide, 15 parts of spherical glass microspheres, 0.3 parts of carbon black, 0.8 parts of 154L yellow, 0.3 parts of bentonite, 4 parts of xylene...

Embodiment 3

[0084] Component A:

[0085] 1) Preparation of 20% polyamide wax additive: 20 parts by weight of JSP-1068 polyamide wax from Japan Phoebe Company and 50 parts by weight of 73006D (80%) high-solid and low-viscosity hydroxyl acrylic resin from Taiwan Changxing Chemical Co., Ltd. After mixing, disperse at 1500r / min until it becomes a transparent pre-gel, and the fineness is detected to be below 20um. Add 30 parts of butyl acetate at a low speed, stir evenly, and set aside.

[0086] 2) According to the proportion by weight, 60 parts of 73006D (80%) high-solid and low-viscosity hydroxyl acrylic resin are metered into the tank, and 1.0 parts of Disponer9250 of Hemings Co., Ltd. of the United States and 1.0 parts of BASF Corporation are added at a speed of 500r / min. EFKA5065, 3 parts of ethyl triethoxypropionate, 30 parts of rutile titanium dioxide, 12 parts of spherical glass microspheres, 0.4 parts of carbon black, 1.4 parts of 154L yellow, 0.8 parts of bentonite, 1 part of xylene,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com