Nano graphene oxide modified double-component aqueous epoxy anti-corrosion coating and preparation method thereof

A graphene modification, water-based epoxy technology, applied in the field of coatings, can solve problems such as affecting the health of operators, high relative density of zinc powder, reduced corrosion resistance, etc., to eliminate fire hazards and achieve high mechanical strength of paint films. , the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

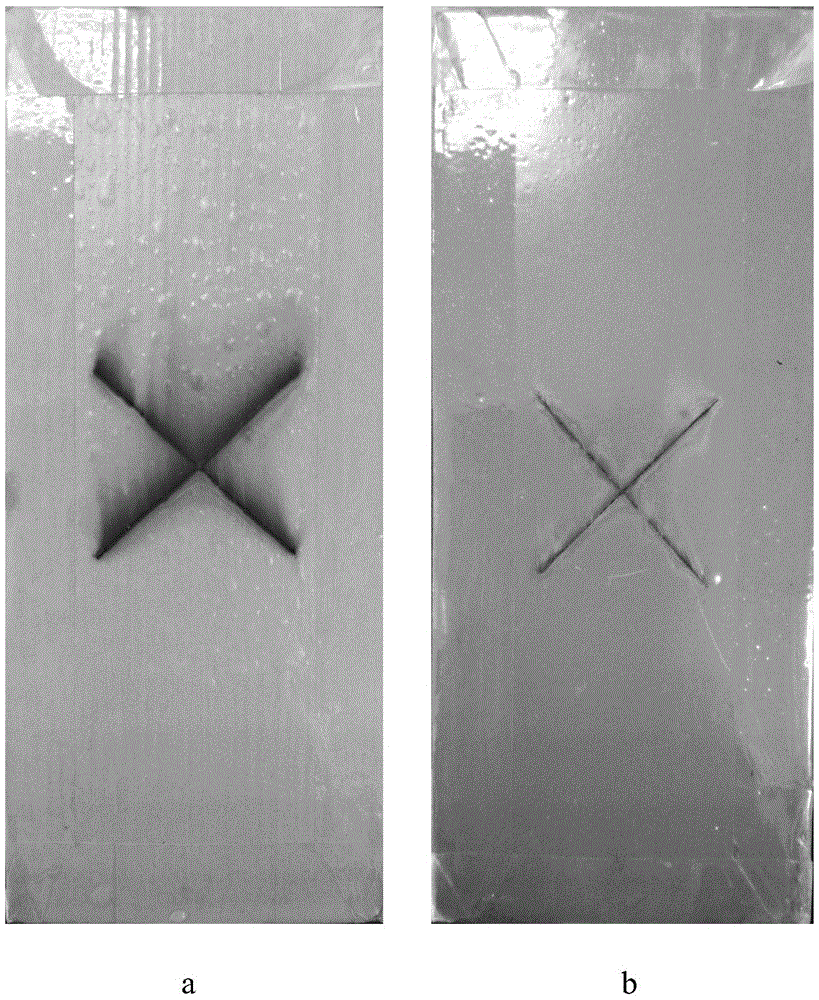

Image

Examples

Embodiment 1

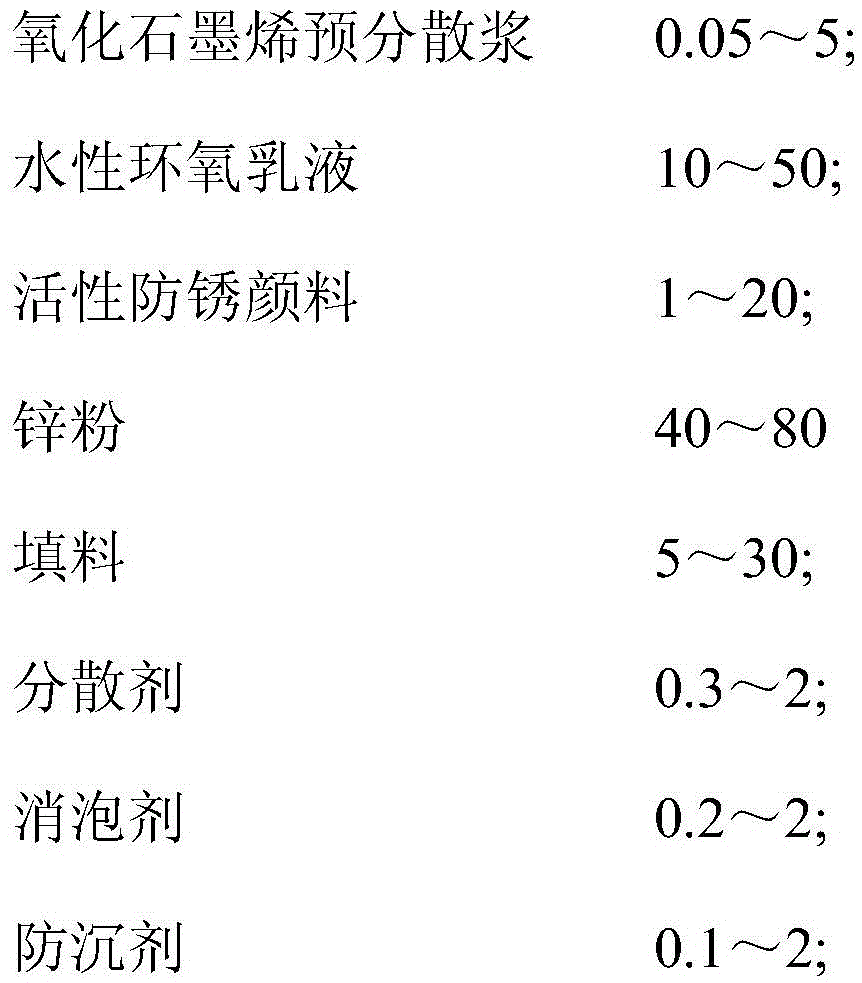

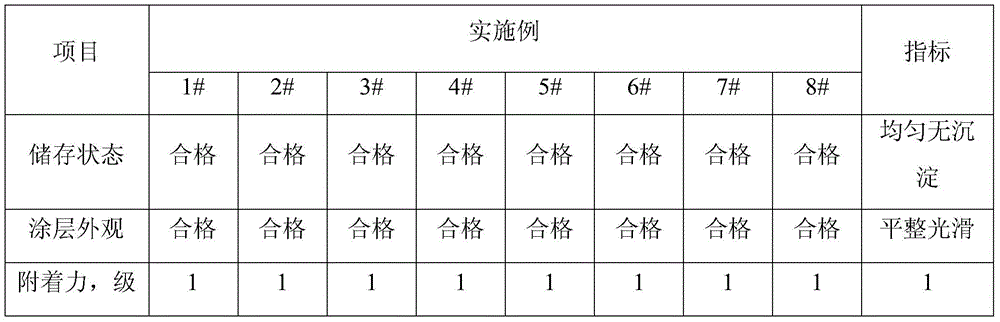

[0025] A nano-graphene oxide modified two-component water-based epoxy anti-corrosion coating, firstly, graphene oxide is prepared into a 20% aqueous solution, and 1% dispersant and 10% bisphenol A water-based epoxy resin emulsion are added at the same time. The dispersant is ground to 1000 mesh particles to obtain graphene oxide pre-dispersed slurry. Below by weight ratio, with graphene oxide pre-dispersed slurry 0.1, bisphenol A type aqueous epoxy resin emulsion 20, zinc phosphate 1, aluminum tripolyphosphate 5, 500 mesh flake zinc powder 70, water-based bentonite 2, mica powder 10 , dispersing agent 0.5, defoaming agent 0.3, anti-settling agent 0.2, stir evenly, disperse at high speed and grind to a fineness of less than 35 microns by grinding equipment to obtain the A component of the graphene oxide modified two-component water-based epoxy anti-corrosion coating . At the same time, 40 parts of the polyamide modified epoxy curing agent is diluted with 60 parts of deionized ...

Embodiment 2

[0027] A nanometer graphene oxide modified two-component water-based epoxy anti-corrosion coating, firstly, graphene oxide is prepared into a 30% aqueous solution, and 2% dispersant and 20% bisphenol F-type water-based epoxy resin emulsion are added at the same time. The dispersant is ground to 500 mesh particles to obtain graphene oxide pre-dispersed slurry. Below by weight ratio, will graphene oxide pre-dispersed slurry 1, bisphenol F type aqueous epoxy resin emulsion 20, zinc phosphate 2, aluminum tripolyphosphate 3, 1000 mesh spherical zinc powder 60, water-based bentonite 1, light calcium carbonate 7. Dispersing agent 0.5, defoaming agent 0.4, and anti-settling agent 0.2 are mixed evenly, dispersed at high speed and ground to a fineness of less than 35 microns by grinding equipment to obtain group A of graphene oxide modified two-component water-based epoxy anti-corrosion coating point. At the same time, 60 parts of polyamide modified epoxy curing agent is diluted with 4...

Embodiment 3

[0029] A nano-graphene oxide modified two-component water-based epoxy anti-corrosion coating. First, graphene oxide is prepared into a 40% aqueous solution, and 1% dispersant and 5% bisphenol F type water-based epoxy resin emulsion are added at the same time. The dispersant is ground to 2000 mesh particles to obtain graphene oxide pre-dispersed slurry. Below by weight ratio, will graphene oxide pre-dispersed slurry 5, bisphenol A type aqueous epoxy resin emulsion 10, aluminum tripolyphosphate 5, 2000 mesh flake zinc powder 70, calcined kaolin 2, mica powder 8, dispersant 0.4 , 0.4 of defoamer, and 0.4 of hydroxycellulose, stir evenly, disperse at high speed and grind to a fineness of less than 35 microns by grinding equipment to obtain component A of the graphene oxide modified two-component waterborne epoxy anti-corrosion coating. At the same time, 60 parts of aliphatic amine modified epoxy curing agent is diluted with 40 parts of deionized water to obtain B component of grap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com