Resin composition and presoaking material and laminated board using same

A resin composition and resin technology, applied in the field of prepreg, laminate, and resin composition, can solve problems such as adverse effects on dielectric properties, influence on prepregs, poor compatibility, etc., and achieve dielectric properties and peel strength. High, excellent appearance, the effect of improving dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] (1) Preparation of prepolymer solution of epoxy resin modified polyphenylene ether resin:

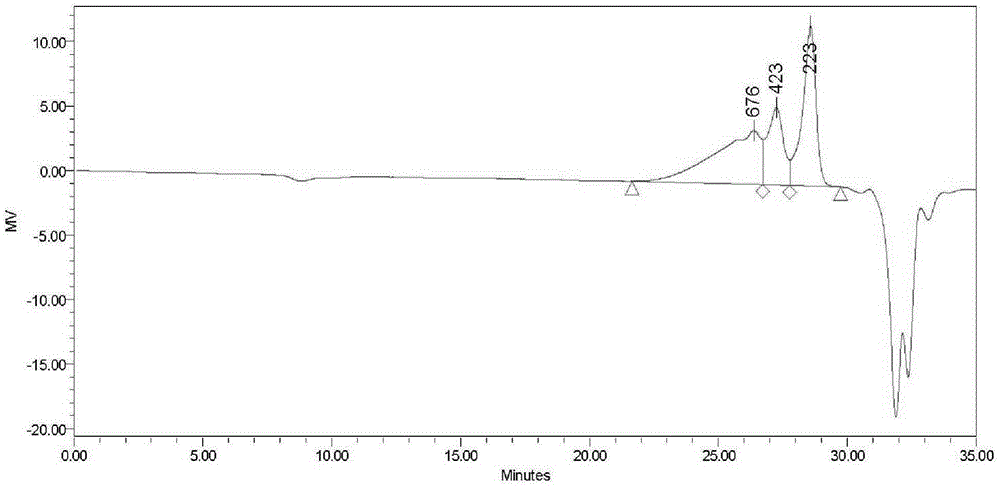

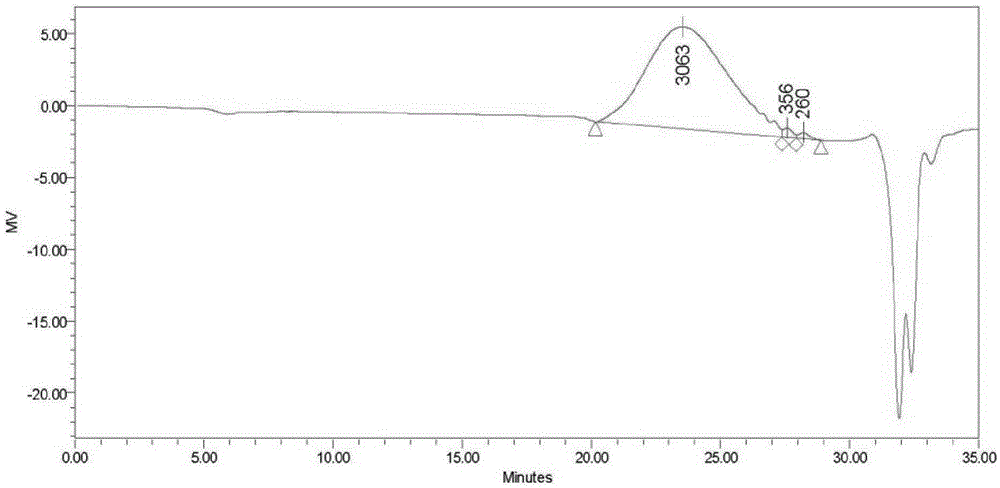

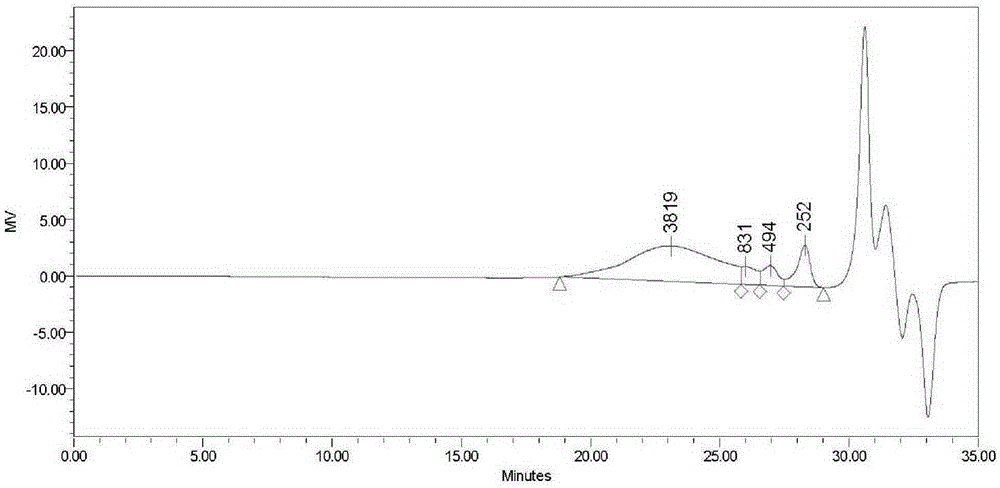

[0098] Dissolve 50 parts of bisphenol A epoxy resin and 0.005 part of pyridine under heating and stirring; then dissolve 50 parts of solid polyphenylene ether resin in xylene solvent to make polyphenylene ether resin with a solid content of 30-70%. The ether resin solution was slowly added dropwise into the above epoxy resin melt, and after the dropwise addition was completed, it was stirred and reacted at 145° C. for 6 hours to obtain a prepolymer solution of epoxy resin modified polyphenylene ether resin. The GPC charts of the prepolymer products of epoxy resin, polyphenylene ether and epoxy resin modified polyphenylene ether resin are as follows: figure 1 , figure 2 and image 3 shown.

[0099] (2) Preparation of prepolymer composition of epoxy resin modified polyphenylene ether resin

[0100] With the prepolymer of step (1) epoxy resin modified polyphenylene ether resin ...

Embodiment 2

[0104] (1) Preparation of prepolymer solution of epoxy resin modified polyphenylene ether resin:

[0105] Dissolve 50 parts of DCPD epoxy resin and 0.005 parts of pyridine under heating and stirring; then dissolve 50 parts of solid polyphenylene ether resin in xylene solvent to make a polyphenylene ether resin solution with a solid content of 30-70%. , slowly added dropwise into the above epoxy resin melt, after the dropwise addition was completed, stirred and reacted at 145° C. for 6 hours to obtain a prepolymer solution of epoxy resin-modified polyphenylene ether resin. The weight average molecular weight was 6,200 in the molecular weight measurement by GPC of the prepolymer of the obtained epoxy resin-modified polyphenylene ether resin.

[0106] (2) Preparation of prepolymer composition of epoxy resin modified polyphenylene ether resin

[0107] With 60 parts by weight of step (1) prepolymer of epoxy resin modified polyphenylene ether resin, 20 parts by weight of phenol nov...

Embodiment 3

[0111] (1) Preparation of prepolymer solution of epoxy resin modified polyphenylene ether resin:

[0112] Dissolve 20 parts of DCPD epoxy resin and 0.005 part of pyridine under heating and stirring; then dissolve 50 parts of solid polyphenylene ether resin in toluene solvent to make a polyphenylene ether resin solution with a solid content of 30-70%. Slowly added dropwise to the above epoxy resin melt, and after the dropwise addition was completed, stirred and reacted at 145°C for 6 hours to obtain a prepolymer solution of epoxy resin modified polyphenylene ether resin. The weight average molecular weight was 6,200 in the molecular weight measurement by GPC of the prepolymer of the obtained epoxy resin-modified polyphenylene ether resin.

[0113] (2) Preparation of prepolymer composition of epoxy resin modified polyphenylene ether resin

[0114] With 60 parts by weight of step (1) prepolymer of epoxy resin modified polyphenylene ether resin, 20 parts by weight of phenol novol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com