Low-odor and low-volatile automobile heavy sound insulation mat material and preparation method thereof

A low-volatility, low-odor technology, which is applied in low-volatility automotive heavy-duty sound-insulating pad materials and its preparation, and low-odor fields. It can solve the problems of poor feeding ability, material odor and volatiles that cannot meet consumer requirements, low odor, etc. problem, to achieve the effect of improving the devolatilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

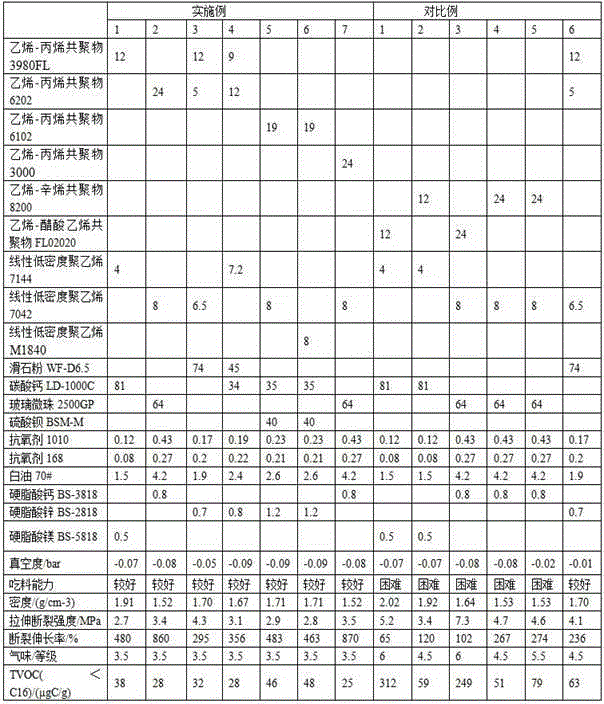

Embodiment 1-7 and comparative example 1-4

[0056] According to the formula in Table 1, first weigh ethylene-propylene copolymer, linear low-density polyethylene, lubricant, and antioxidant and add them to a high-speed mixer and mix for 3-5 minutes, wherein the speed of the high-speed mixer is 200 rpm-300 rpm; then weigh the inorganic filler and add it to the high-speed mixer and mix for 3-5 minutes, wherein the speed of the high-speed mixer is 200 rpm-300 rpm; add the above-mentioned mixed particles into the twin-screw extruder Melt extrusion, granulation, drying, cooling and packaging are carried out. Among them, the twin-screw extruder is a double-vacuum design (that is, a vacuum pump is installed in the 6th zone and 9th zone respectively), and the vacuum degree is ≤ -0.05bar. The screw length-to-diameter ratio of the twin-screw extruder is 48, and the screw speed is 480rpm. The feeding speed is 1000kg / h, and the temperature of the twin-screw extruder is 200°C, 200°C, 200°C, 210°C, 210°C, 205°C, 205°C, 205°C, 200°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com