Method and equipment for preparing diazomethane

A diazomethane and equipment technology, applied in the field of diazomethane preparation, can solve the problems of low raw material cost, short process route, high yield, etc., and achieve the effects of reduced production cost, high yield, and avoiding safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

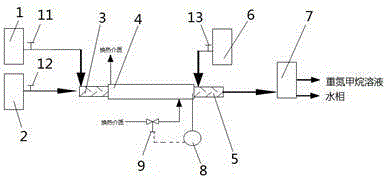

Image

Examples

Embodiment 1

[0034] The preparation method of diazomethane comprises the following steps:

[0035] Under completely sealed conditions, take the raw material N-nitroso-methylurea liquid, the molar mass fraction is 2.32 mol / liter, with the speed of 822 liters per hour (its flow rate is: V (A) * C=822 / 1000m3 / h×2.32kg / m3=1.907kg mol / h) and 25.1% NaOH are simultaneously injected into the static mixer at the feed end at a rate of 238 liters per hour, and the reaction temperature is controlled at -5°C, 30~ After 90 seconds, the reaction is complete, and the diazomethane generated is injected into the extractant ether, and the flow rate of the ether (m 3 / h) is 0.5 times the flow rate (kgmol / h) of the raw material compound N-nitroso-methylurea, and the flow rate is 954 liters per hour (extractant flow rate: 0.5×1.907=0.954 cubic meters / hour). Extract for 15 minutes, separate the water phase, the oil phase is diazomethane solution, the production rate of diazomethane solution is 946 liters / hour, ...

Embodiment 2

[0041] Under completely sealed conditions, the raw material 1-methyl-3-nitro-1-nitrosoguanidine solution, its molar mass fraction is 1.7 mol / liter, with the KOH of 791 liters of speed and mass fraction 25.0% per hour At a speed of 269 liters per hour, it enters the static mixer at the feed end synchronously, and the reaction temperature is controlled at -5°C. After 30 to 90 seconds, the reaction is complete, and the generated diazomethane is injected into the extraction agent tetrahydrofuran. The flow rate of tetrahydrofuran (m 3 / h) is 3.0 times the liquid flow rate (kgmol / h) of the raw material compound 1-methyl-3-nitro-1-nitrosoguanidine, the continuous feeding rate of THF is 4034 liters / hour, and the extraction is carried out for 30 minutes, The aqueous phase and the diazomethane solution were separated, and the diazomethane solution was obtained at a rate of 4045 liters / hour, with a content of 11.19 g / liter and a diazomethane production capacity of 45.26 kg / hour.

[0042]...

Embodiment 3

[0044] Under completely sealed conditions, the raw material N-methyl-N-nitroso-p-toluenesulfonamide solution has a molar mass fraction of 1.2 mol / liter, at a speed of 887 liters per hour and with a mass fraction of 25.1% NaOH At a rate of 173 liters per hour, it enters the static mixer at the feed end synchronously, and the reaction temperature is controlled at -10°C. After 30 to 90 seconds, the reaction is complete. The generated diazomethane is extracted with methyl tert-butyl ether, and methyl tert-butyl The flow rate of base ether (m 3 / h) is 0.8 times of the flow rate (kgmol / h) of the raw material compound N-methyl-N-nitroso-p-toluenesulfonamide solution, the injection flow rate is 852 liters / hour, the extraction is for 15 minutes, and the aqueous phase and the Diazomethane solution, namely 847 liters / hour of diazomethane solution, content of 40.2 g / liter, diazomethane production capacity of 34.0 kg / hour.

[0045] Conclusion: The yield of diazomethane is up to 76%, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com