Starting method of normal-temperature low-ammonia-nitrogen plug-flow type half-nitritation process

A plug-flow, low-ammonia-nitrogen technology, applied in chemical instruments and methods, aerobic and anaerobic process treatment, water/sludge/sewage treatment, etc., can solve difficult engineering applications, stable operation problems, reactors Crash and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiments, but the application of the present invention is not limited to this.

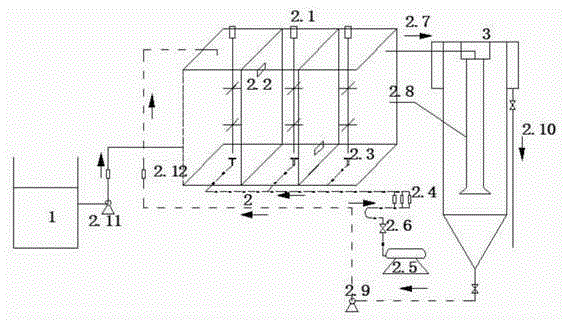

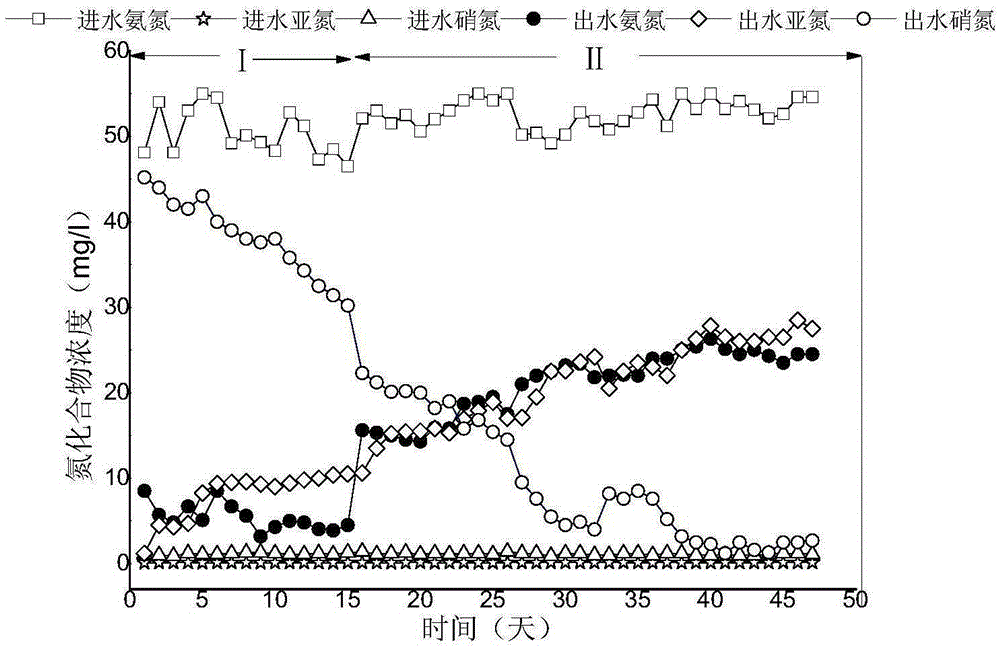

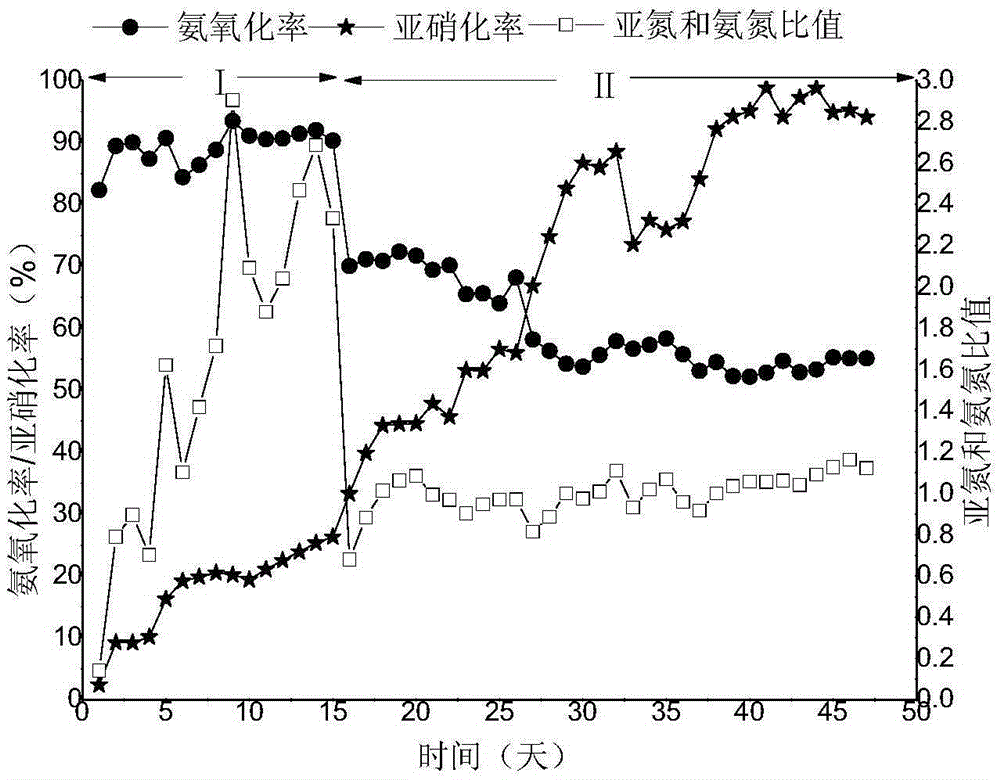

[0029] The continuous flow reactor used in the present invention has a total volume of 120L and a vertical flow type secondary settling tank with a volume of 60L. An aeration device is installed at the bottom of the reactor, and a stirring device is installed at the top of the reactor. The sludge is separated and returned to the reaction through the secondary settling tank. In the first compartment of the device, the effluent flows from the overflow weir on the upper part of the second settling tank. The test water is artificial simulated wastewater, with (NH 4 ) 2 SO 4 Is the matrix, Concentration 50±5mg / L, pH through NaHCO 3 Adjust between 7.5-8.2, while using NaHCO 3 Provide inorganic carbon source, add proper amount of Ca in the feed water 2+ , Mg 2+ And the trace elements needed for the growth of microor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com