Lifting device for upper platform of automatic layout machine for photovoltaic cell strings

A lifting device, automatic typesetting technology, used in conveyors, transportation and packaging, etc., can solve the problems of hidden quality problems, product quality stability control buried, affecting typesetting work accuracy, etc., to ensure position accuracy, product quality improvement, The effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

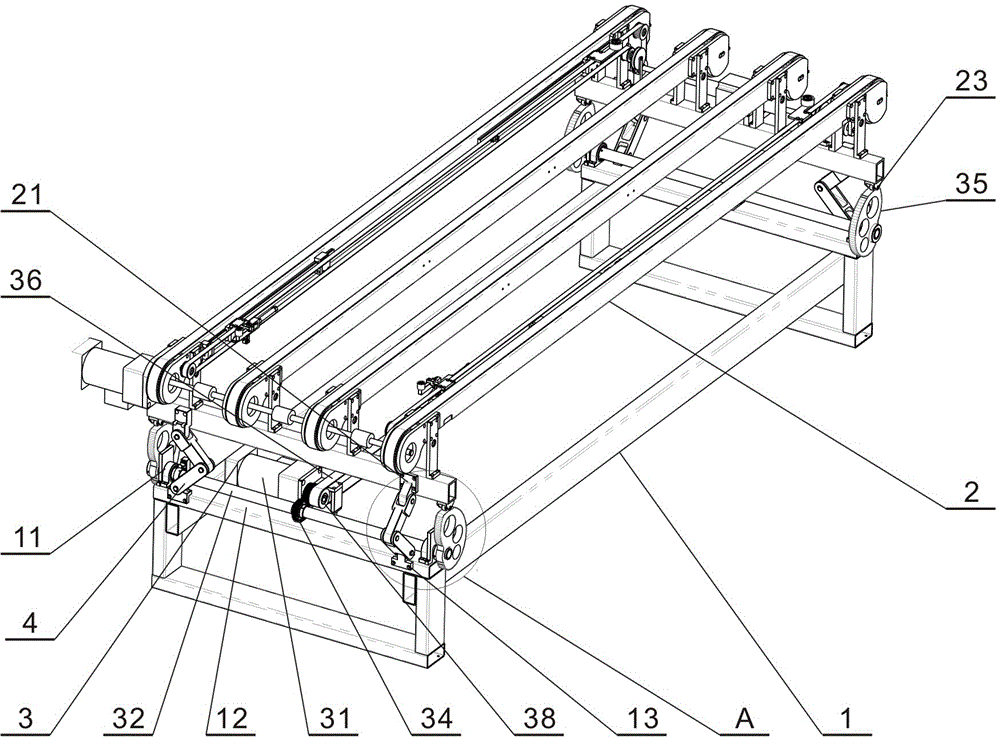

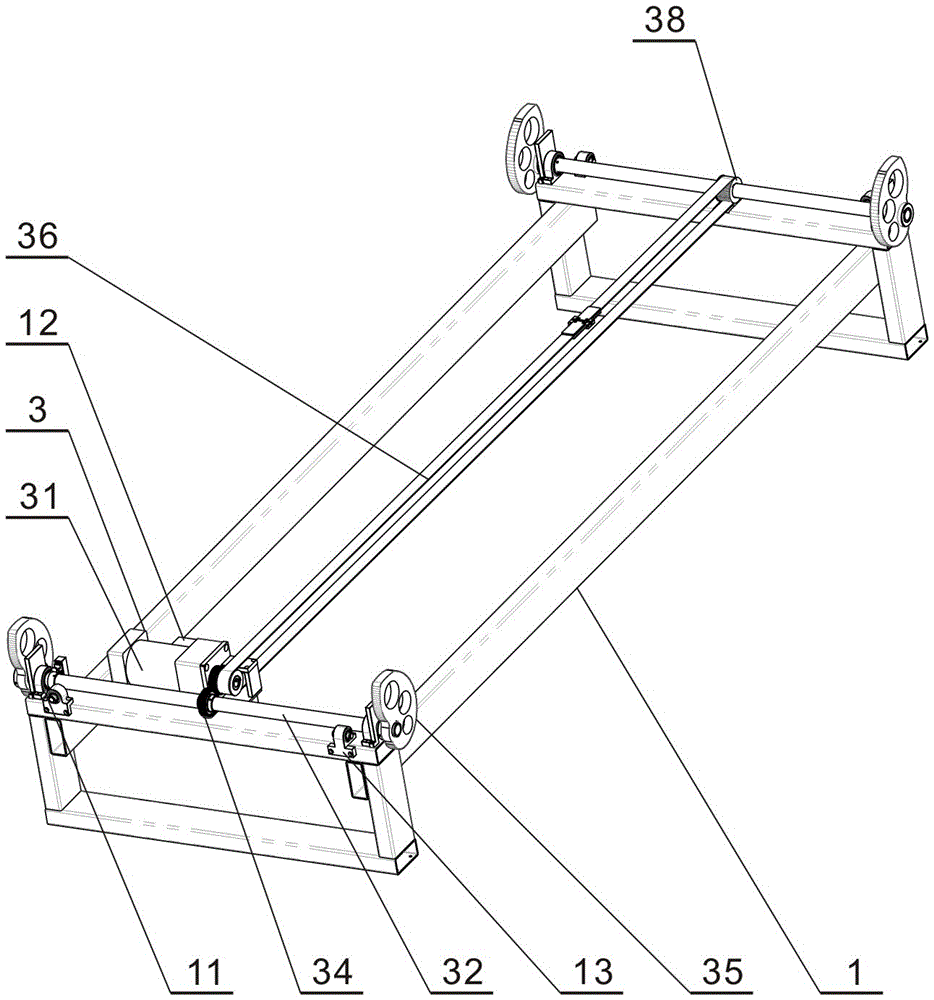

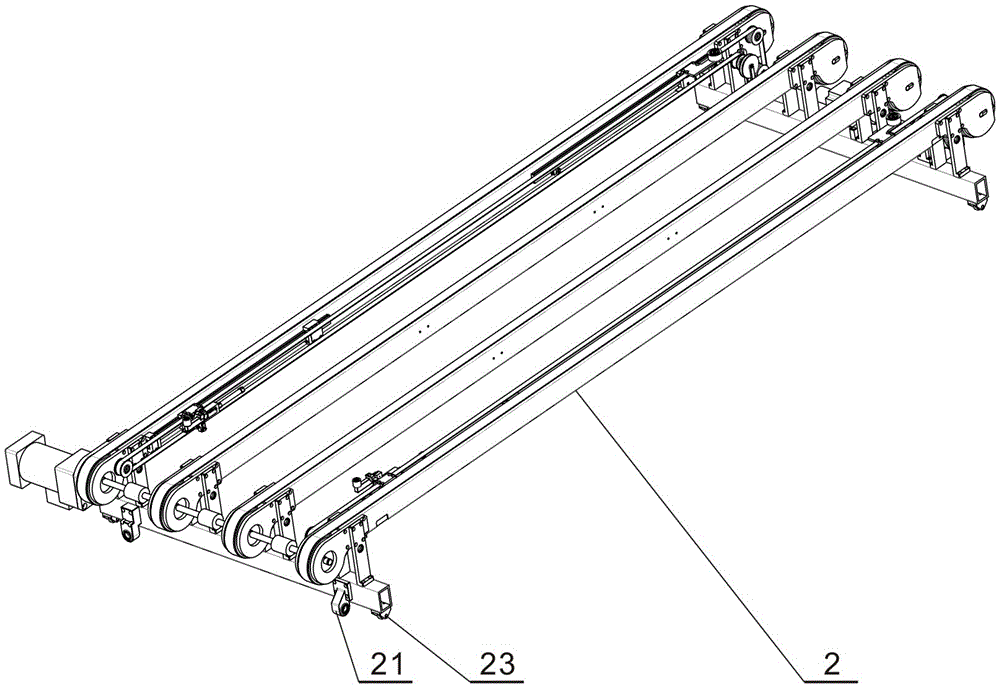

[0019] The invention is used in the production process of the photovoltaic cell, and is a device for the photovoltaic cell string typesetting machine to carry out glass conveying, positioning and transfer. The specific working process is as follows:

[0020] refer to Figure 1 ~ Figure 4 , when the glass is transported to the upper platform 2, the lifting motor 31 starts, and the output shaft of the lifting motor 31 drives the two drive shafts 32 to rotate in reverse through the gear 34 and the synchronous pulley 38, and drives the two drive shafts arranged symmetrically on each other. The lifting cam 35 on the power transmission shaft 32 rotates in the opposite direction. With the rotation of the lifting cam 35, the wheel rim of the lifting cam 35 drives the guide wheel 23 of the upper platform 2 to raise the upper platform 2. The open line segment and the concentric circle curve segment are formed, when the involute of the guide wheel 23 and the lifting cam 35 a When the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com