A Friction Stir Welding Method Based on Double-pass Offset Welding

A welding method and friction stir technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as limited application range and shape limitation of repair welding materials, and achieve the effect of increasing the elongation rate of the joint and improving the elongation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

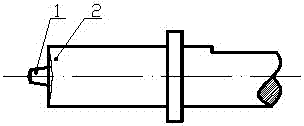

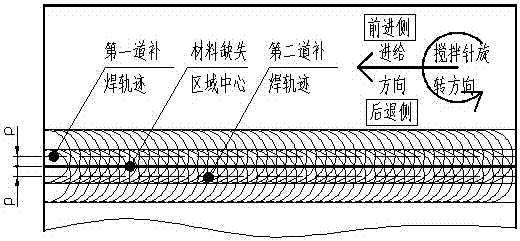

[0027] see figure 1 and 2 , a friction stir welding method based on double-pass offset welding, the steps are as follows: according to the material properties and geometric characteristics to be welded, select the appropriate stirring needle and welding process parameters, the selected stirring needle is as follows figure 1 As shown, there is a stirring needle tip 1 and a stirring needle shoulder 2, and the width of the material missing area is set to 2p, and repair welding is carried out in two steps: the first step is symmetrical to the center of the material missing area, and the welding track is moved to one side Row offset, the distance is p, so that after the offset, the symmetrical center line is located on the retreating side of the welding track, and welding is performed; the second step is to offset the welding track to the other side of the symmetric line, and the offset distance is also p, The center line of symmetry after the offset is located on the advancing si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com