External nozzle twin-wire co-pool narrow-gap GMAW torch

A narrow gap, eutectic pool technology, applied in the direction of electrode characteristics, welding equipment, welding accessories, etc., can solve the problems that the molten pool can not form a good protection effect, complex structure, easy to form turbulent flow, etc., to achieve good gas protection effect , Simplify the structure of the welding torch and avoid the effect of entraining air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

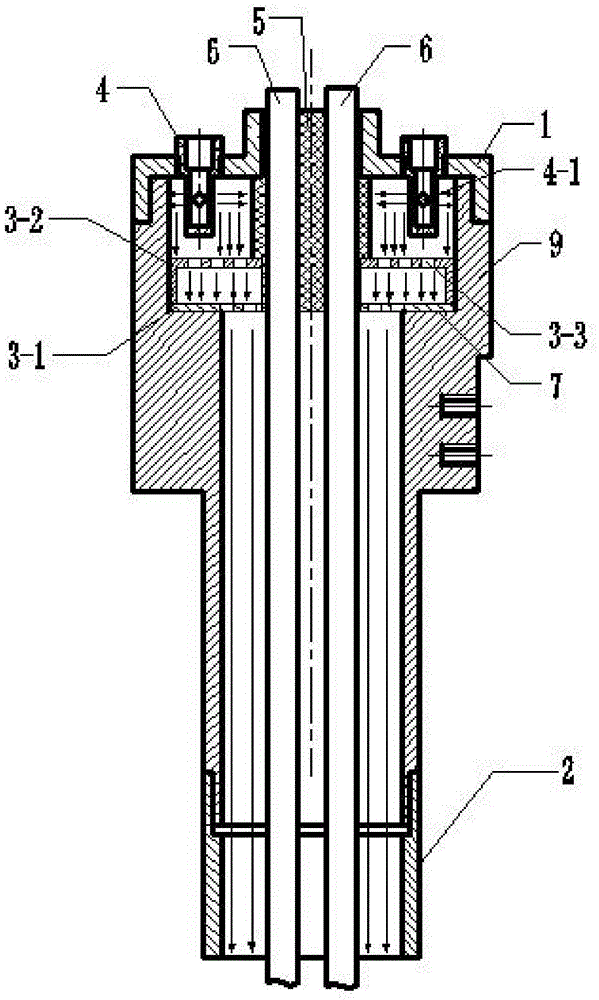

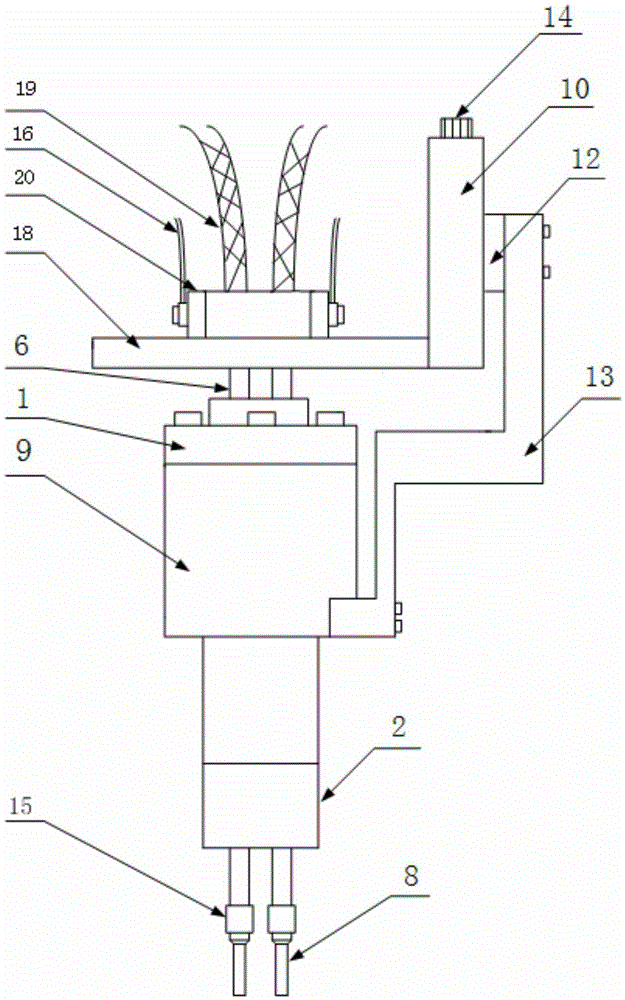

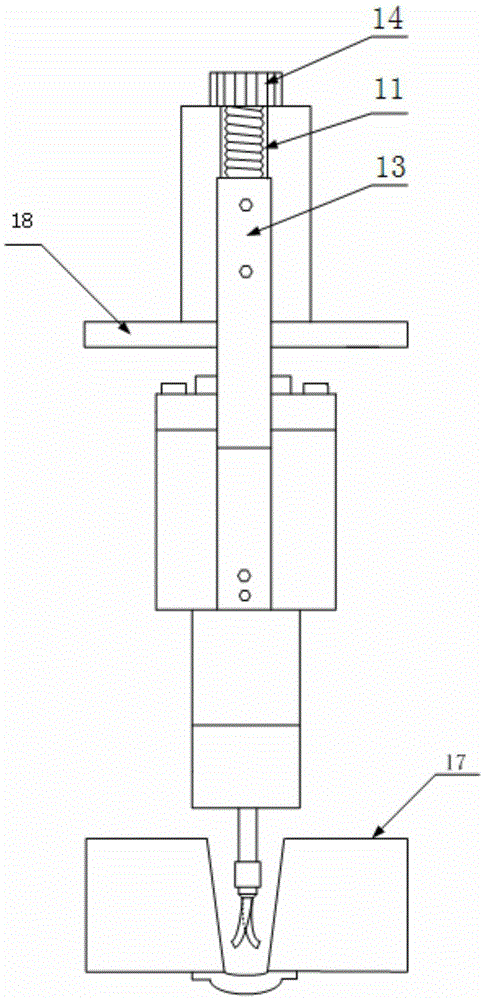

[0018] Specific embodiment 1: In this embodiment, the GMAW welding torch of the external nozzle double-wire eutectic pool narrow gap includes a welding torch body, two conductive rods 6, two conductive tips 8, a first gas sieve plate 3-1, a second gas Sieve plate 3-2 and gas plug 4, wherein the welding torch main body is made up of loam cake 1, gun barrel body 9 and nozzle 2, and loam cake 1 and nozzle 2 are connected to the upper end face and the lower end face of gun barrel body 9 by thread respectively to form a long Tubular torch main body has an annular groove on the wall of the upper part of the gun barrel body 9, the pipe diameter of the gun barrel body 9 becomes smaller below the annular groove, and the connection between the annular groove and the gun barrel body 9 diameter becomes smaller Boss 7 is formed, an insulating sleeve hole and a plurality of air inlet holes are opened on upper cover 1, and air plug 4 is inserted in each air inlet hole. The opening direction ...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the upper cover 1 and the barrel body 9 are made of aluminum alloy.

[0021] In this embodiment, the aluminum alloy material can be used to reduce the weight of the welding torch.

specific Embodiment approach 3

[0022] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that the nozzle 2 is made of red copper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com