A polarizer self-adhesive protective film

A self-adhesive protective film, polarizer technology, applied in optics, optical components, polarizing components, etc., can solve the problems of glue residue on the surface of polarizer, irritating odor, cost increase, etc., to achieve firm adhesion, reduce friction coefficient, scratch less damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

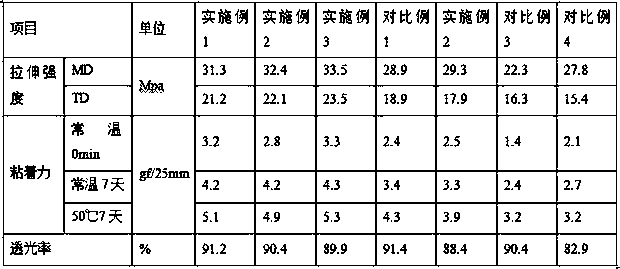

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with specific embodiments, so that those skilled in the art can implement it with reference to the description.

[0022] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

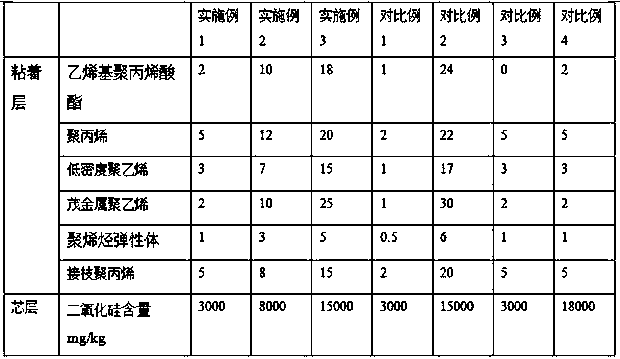

[0023] The invention provides a self-adhesive protective film for polarizers, comprising an adhesive layer, a core layer and a surface layer that are in contact with each other in sequence, and the adhesive layer is formed by extruding and blowing the following materials by weight:

[0024] Vinyl polyacrylate 2~18 parts;

[0025] 5~20 parts of polypropylene;

[0026] Low-density polyethylene 3~15 parts;

[0027] Metallocene polyethylene 2~25 parts;

[0028] 1~5 parts of polyolefin elastomer;

[0029] 2~15 parts of grafted polypropylene.

[0030] Among them, the preparation method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap