Horizontal separator manual blowdown device and method

A horizontal separator and sewage device technology, which is applied in chemical instruments and methods, cleaning methods and utensils, cleaning hollow objects, etc., can solve the problems of affecting separation effect, uneconomical, disturbing the flow field of the separator, etc., and achieves flexible operation. , the effect of easy implementation and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

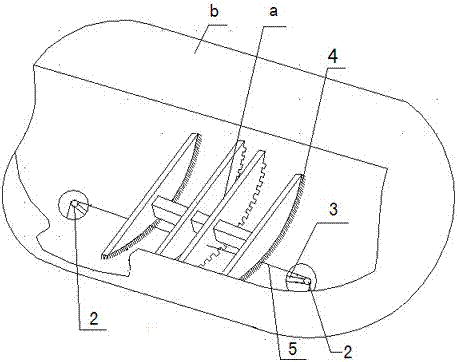

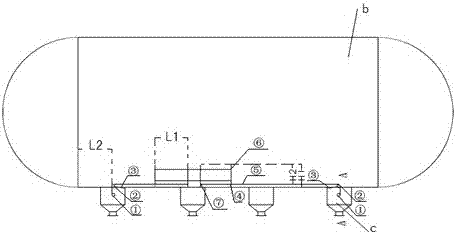

[0030] Attached Figure 1-7 , To further describe the present invention:

[0031] The manual sewage discharge device of the horizontal separator mentioned in the present invention includes a main structure a and a pulley spool device;

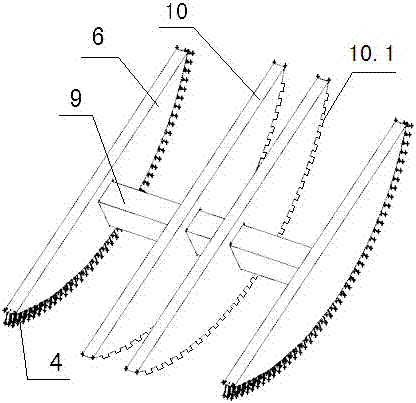

[0032] Inside the horizontal separator b, a main body structure a is provided. The main body structure a includes a brush 4, an outer sand scraper 6, a main shaft 9 and an inner support plate 10. The bottom of the outer sand scraper 6 is curved The area is provided with a brush 4, the outer sand scraping board 6 is connected to the inner support plate 10 through the main shaft 9, and the bottom of the inner support plate 10 is provided with I-shaped oblique serrations 10.1. On the one hand, the oblique serrations make the support plate also have A certain amount of sand scraping, the second aspect, reduces the resistance of the support plate; the bottom curvature radius of the outer sand scraping plate 6 (including the brush 4) and the inner suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com