Beneficiation method for separating copper-nickel sulfide ore from serpentine gangue

A technology of copper-nickel sulfide ore and beneficiation method, applied in solid separation, flotation and other directions, can solve problems such as poor dispersant effect and dispersant consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

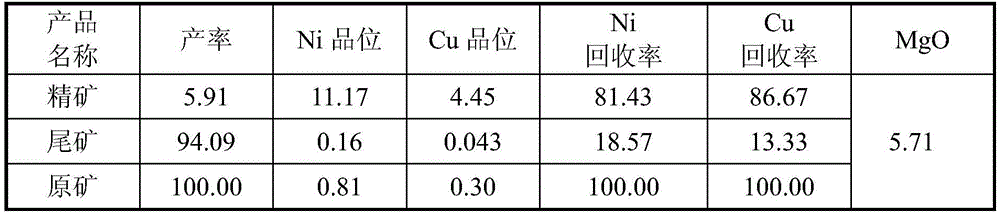

Embodiment 1

[0023] Raw material: a copper-nickel sulfide ore in Xinjiang, its main chemical composition is wt%

[0024] Ni

Cu

MgO

0.81

0.30

27.2

[0025] The process is: Add 3kg / t of ore sodium carbonate into the mill, grind the ore to -0.074mm, accounting for 68%; transfer the ground pulp to the flotation tank, add 200g / t of ore regulator polo Sham, ultrasonic treatment for 10min while stirring, the ultrasonic frequency is 20KHz, the intensity of ultrasonic treatment is 150W, after ultrasonic treatment, add 120g / t ore collector Y89 xanthate, 20g / t ore foaming agent MIBC Rough separation to obtain rough separation concentrate and rough separation tailings; add 80g / t ore poloxamer to the rough separation tailings, and 60g / t ore Y89 xanthate for the first sweep to obtain the first sweep Tailings and scavenging, the first scavenging returns to roughing; 30g / t ore Y89 xanthate is added to the first scavenging tailings for the second scavenging operation, a...

Embodiment 2

[0030] Raw material: A low-grade copper-nickel sulfide ore sample in Xinjiang, its main chemical composition is (wt%)

[0031] Ni

Cu

MgO

0.39

0.08

38.9

[0032] The process is: add 5kg / t ore sodium carbonate into the mill, and grind the ore to -0.074mm, accounting for 75%. Transfer the ground pulp to the flotation tank, add 350g / t ore regulator poloxamer, and carry out ultrasonic treatment for 20 minutes while stirring. The frequency of ultrasonic wave is 20KHZ, and the intensity of ultrasonic treatment is 150W. Collector pentaxanthate and 35g / t ore foaming agent MIBC are used for roughing to obtain roughing concentrate and roughing tailings. Add 120g / t ore poloxamer and 80g / t ore pentaxanthate to the roughing tailings for the first scavenging to obtain the first scavenging tailings and scavenging medium, and the first scavenging medium Return to roughing; add pentaxanthate of 40g / t ore to the tailings of the first sweeping for the second ...

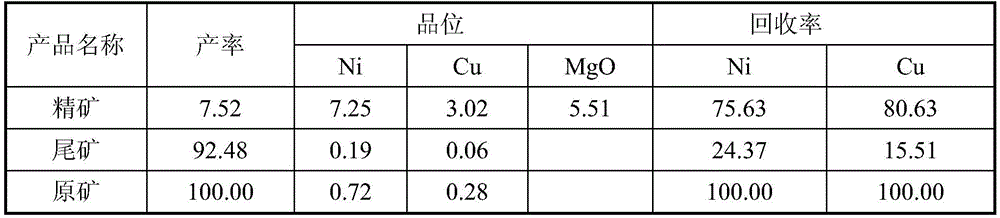

Embodiment 3

[0037] Raw material: a copper-nickel sulfide ore in Sichuan, its main chemical composition is (wt%)

[0038] Ni

Cu

MgO

0.72

0.27

21.37

[0039] The process is: add 2.5kg / t ore sodium carbonate into the mill, and grind the ore to -0.074mm, accounting for 70%. Transfer the ground pulp to the flotation tank, add 250g / t ore regulator poloxamer, and carry out ultrasonic treatment for 10 minutes while stirring. The frequency of ultrasonic wave is 30KHZ, and the intensity of ultrasonic treatment is 120W. Collector butyl xanthate, 20g / t ore foaming agent MIBC for roughing to get roughing concentrate and roughing tailings. Add 100g / t of ore poloxamer and 40g / t of ore to the roughing tailings to carry out the first sweeping to obtain the first sweeping tailings and sweeping ore, and the first sweeping ore Return to roughing; add 20g / t ore dixanthate to the tailings of the first sweep to carry out the second sweeping operation to obtain the sweeping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com