Preparation method of rice products with low content of heavy metal

A heavy metal content technology, applied in the field of grain deep processing, can solve the problems of complex cleaning, easy clogging, and lower cadmium removal rate, and achieve the effect of improving water solubility, increasing added value, and being easy to realize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

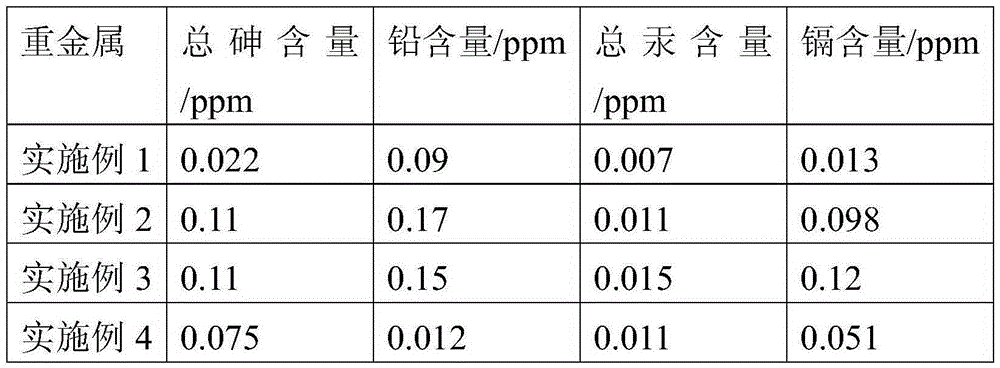

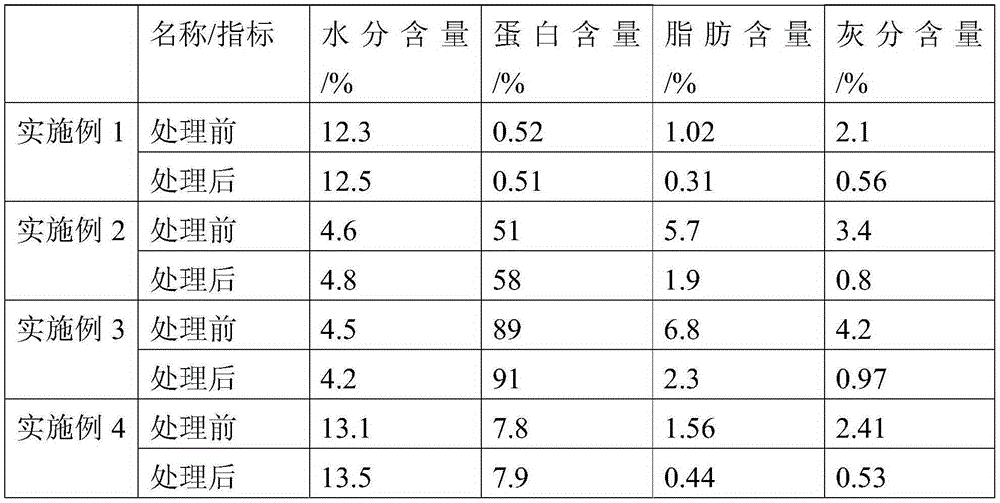

Embodiment 1

[0031] A method for preparing rice products with low heavy metal content, comprising the steps of:

[0032] (1) pulping: the rice product rice flour (the protein dry basis content is 0.52%, the total arsenic content is 0.42ppm, the lead content is 0.23ppm, the total mercury content is 0.02ppm, and the cadmium content is 0.25ppm) water pulping, the quality The concentration is 15%, and the pH of the slurry is adjusted to 6.0 with hydrochloric acid;

[0033] (2) Enzymolysis: add 10 U / g of transglutaminase based on the weight of protein in the slurry to the slurry prepared in step (1), and react for 30 minutes at a temperature of 50° C.;

[0034](3) Complexation: Add complex acid complexing agent (the molar ratio of lactic acid, tartaric acid, hydrochloric acid is 1.5:1.5:1) to adjust the pH value to 4.8 in the slurry processed through step (2), add simultaneously relative to rice flour A compound salt solution of NaCl and KCl with a mass of 0.1% (the molar ratio of NaCl to KCl ...

Embodiment 2

[0038] A method for preparing rice products with low heavy metal content, comprising the steps of:

[0039] (1) Slurry: the rice product rice protein powder (the protein dry basis content is 51%, the total arsenic content is 1.43ppm, the lead content is 0.38ppm, the total mercury content is 0.035ppm, and the cadmium content is 1.57ppm) with water , the mass concentration is 10%, and the pH of the slurry is adjusted to 6.0 with hydrochloric acid;

[0040] (2) Enzymolysis: Add 20 U / g of transglutaminase based on the weight of protein in the slurry to the slurry prepared in step (1), and react for 30 minutes at a temperature of 55° C.;

[0041] (3) Complexation: Add complex acid complexing agent (the molar ratio of citric acid, malic acid, hydrochloric acid is 2.5:2.5:1) to adjust the pH value to 5 in the slurry processed through step (2), add relative In a compound salt solution of NaCl and KCl with a mass of 0.5% of the rice protein powder (the molar ratio of NaCl to KCl is 4:...

Embodiment 3

[0045] A method for preparing rice products with low heavy metal content, comprising the steps of:

[0046] (1) Slurry: the rice product rice protein powder (protein dry basis content is 89%, total arsenic content is 1.84ppm, lead content is 0.33ppm, total mercury content is 0.036ppm, cadmium content is 1.72ppm) water slurry , the mass concentration is 5%, and the pH of the slurry is adjusted to 6.5 with hydrochloric acid;

[0047] (2) Enzymolysis: add 50 U / g of transglutaminase based on the weight of protein in the slurry to the slurry prepared in step (1), and react at a temperature of 40° C. for 60 minutes;

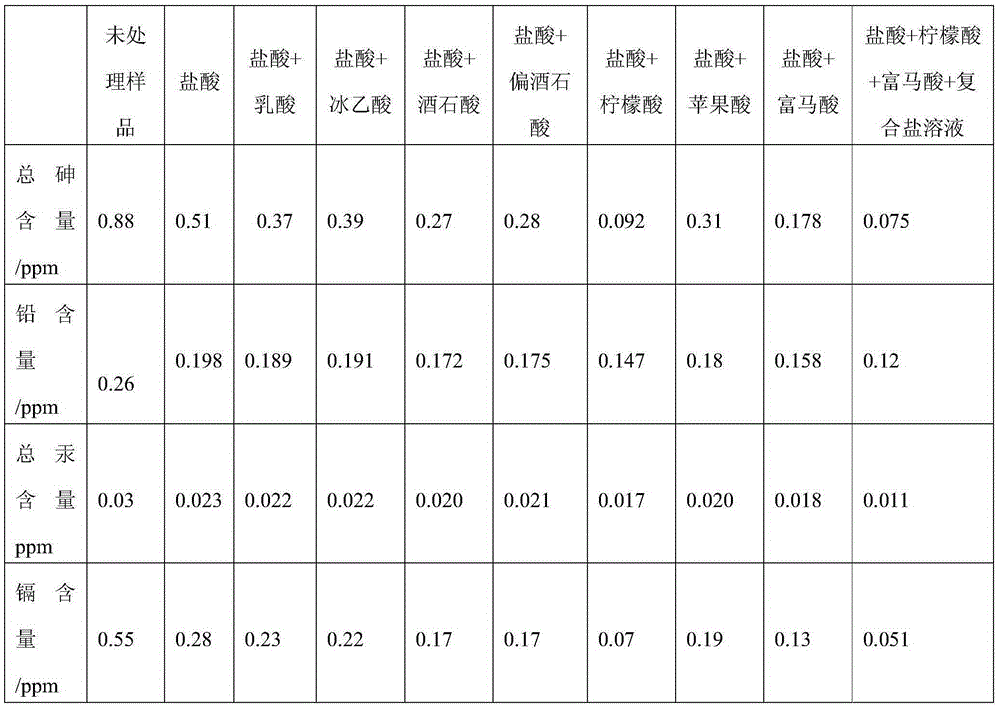

[0048] (3) Complexation: Add complex acid complexing agent (the molar ratio of lactic acid, citric acid, and hydrochloric acid is 2.5:1.5:1) to adjust the pH value to 4 in the slurry processed through step (2), and add relative to A compound salt solution of NaCl and KCl with a mass of 0.5% of the rice protein powder (the molar ratio of NaCl to KCl is 3:1, and the mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com