OLED screen body and preparation method thereof

An electrode layer and substrate technology, applied in the field of OLED, can solve the problems of reducing efficiency and reducing the efficiency roll-off of the screen, and achieve the effects of suppressing the efficiency roll-off, improving the brightness, and improving the uniformity of light emission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

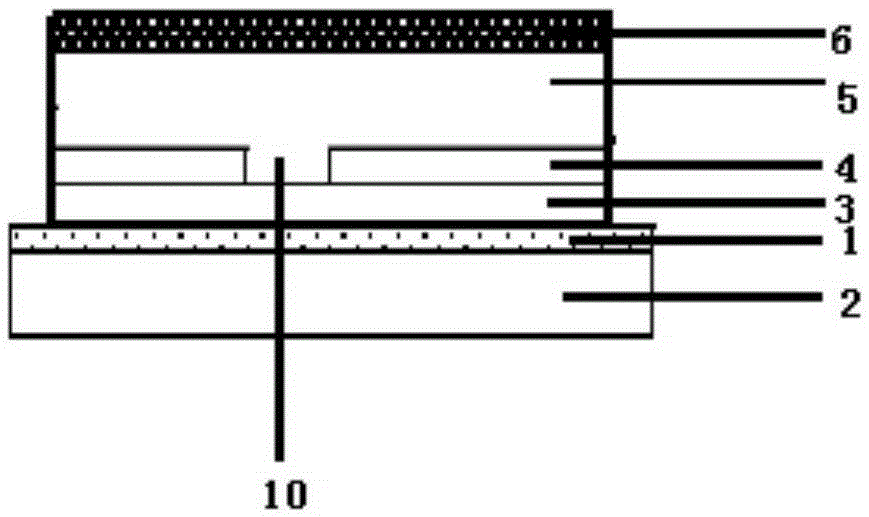

[0030] Embodiment 1 The scattering film layer 1 is arranged on the outside of the substrate

[0031] Such as figure 1 and Figure 4 As shown, a relatively bright OLED panel provided by the present invention includes a substrate 2 and a first electrode layer 3, an organic light-emitting layer 5 and a second electrode layer 6 are stacked on the substrate 2. An insulating film layer is arranged between an electrode layer 3 (anode) and the organic light-emitting layer 5, such as Figure 4 and Figure 5 As shown, the insulating film layer is etched to form parallel or criss-cross light-emitting regions 10, the width of each light-emitting region 10 is 5nm-500um, preferably 50nm-100um, between adjacent light-emitting regions 10 The width of the insulating material layer 4 is 10nm-100um. The thickness of the insulating film layer is 5-20nm. As other implementation manners, the insulating film layer may also be Figure 6 and Figure 7 As shown, its light-emitting area is a para...

Embodiment 2

[0037] Embodiment 2 A scattering film layer 1 is arranged between the substrate and the first electrode layer

[0038] The structure of a relatively bright OLED screen body provided in this embodiment is the same as that in Embodiment 1, such as figure 2 As shown, the scattering film layer 1 is arranged between the substrate 2 and the first electrode layer 3 .

[0039]The preparation method is to arrange a scattering film layer 1 on the substrate 2, coat a layer of insulating film layer on the scattering film layer 1, and the width of the insulating material layer 4 between the adjacent light-emitting regions is 10nm-100um, and then pass the electron beam Photolithography technology carries out photoetching to etch out the light-emitting region 10, the width of the light-emitting region 10 is 5nm-500um, preferably the width is 50nm-100um, and then vapor-deposits the first electrode layer 3, the organic light-emitting layer 5 and the second electrode layer 6 ( cathode), packa...

Embodiment 3

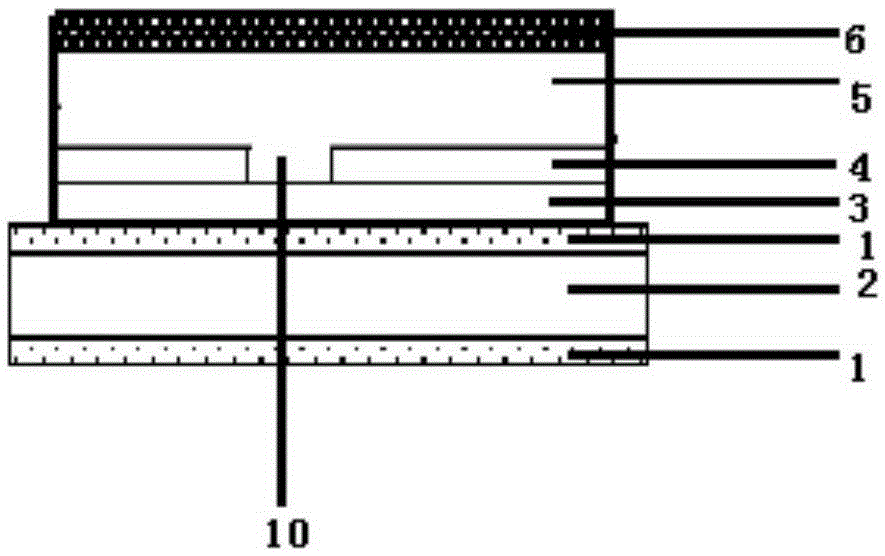

[0040] Embodiment 3 The scattering film layer 1 is respectively arranged on both sides of the substrate

[0041] The structure of a relatively bright OLED screen body provided in this embodiment is the same as that in Embodiment 1, such as image 3 As shown, the two sides of the substrate are respectively provided with scattering film layers 1, that is, one of the scattering film layers 1 is provided between the substrate 2 and the first electrode layer 3, and the other scattering film layer 1 is provided between the The side of the substrate away from the first electrode layer.

[0042] The preparation method is as follows: setting an upper scattering film layer 1 on the substrate 2, coating a layer of insulating film layer on the scattering film layer 1, and then performing photolithography to etch a light-emitting region 10 by electron beam lithography technology. The width of the light-emitting region 10 is 5nm-500um, the preferred width is 50nm-100um, the width of the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com